Description

Key Technical Specifications

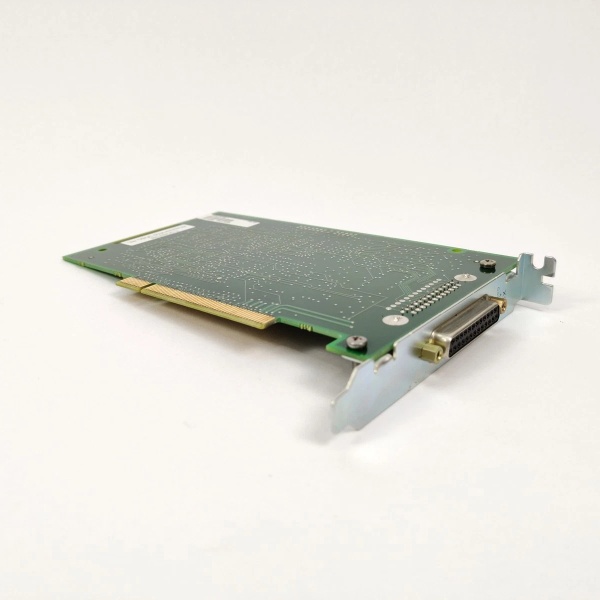

- Model Number: 3HNM08868-1

- Manufacturer: ABB Robotics Division (SafeMove Safety Systems)

- Product Type: Redundant Safety PLC Module for SafeMove 2

- System Compatibility: ABB IRC5 Compact/Single/Dual Robot Controllers, SafeMove 2 Safety Software

- Safety Rating: SIL 3 (per IEC 61508), PL e (per EN ISO 13849-1)

- Safety I/O Channels: 16 configurable (8 safety digital inputs, 8 safety digital outputs)

- Communication Interfaces: FSoE (Failsafe over Ethernet), SafeMove 2 backplane, Ethernet (TCP/IP for diagnostics)

- Power Supply: 24VDC ±10% (redundant inputs, 6W typical, 10W max)

- Isolation Rating: 2500VAC (channel-to-channel, power-to-safety logic)

- Operating Temperature: -20°C to +60°C (ambient, derate >55°C)

- Vibration Resistance: Up to 3g (10-500Hz, IEC 60068-2-6)

- Mounting Type: IRC5 controller DIN rail (35mm), hot-swappable with safety shutdown procedure

- Diagnostics: LED status (power/comm/safe/fault), safety event logging, FSoE link monitoring

- Protection Class: IP20 (module), IP65 (with sealed terminal block)

- Weight: 0.7kg

- Certifications: CE, UL, ATEX, IEC 61508, EN ISO 13849-1 compliant

ABB 3HNM08868-1

Field Application & Problem Solved

In industrial robot cells—power plant auxiliary material handling, refinery hazardous area robotics, automotive welding—the biggest safety risk is unprotected human-machine interaction. Legacy safety systems lack redundancy and SIL 3 compliance, leading to safety incidents, regulatory non-compliance, and production downtime. At a Texas refinery, a non-redundant safety module failed to detect an open safety gate, allowing a robot to operate in a hazardous zone and causing a $300k safety violation penalty.

This module solves critical safety gaps by delivering:

- SIL 3/PL e Compliance: Meets global safety standards for high-risk robot operations

- Redundant Design: Dual power/communication paths eliminate single-point safety failures

- FSoE Communication: Fast, failsafe data transfer between robot and safety sensors (1ms response)

- Integrated Safety I/O: Directly monitors emergency stops, safety gates, and light curtains without external relays

Typical deployments:

- Power Plants: Robot-assisted boiler tube inspection, fuel handling systems (safety interlocks for high-temperature zones)

- Refineries: Hazardous material transfer robots (safety gate monitoring, gas detection interlocks)

- Automotive: Welding robot cells (emergency stop, safe speed control for human-robot collaboration)

- Chemical Plants: Batch processing robot arms (safety zone isolation, pressure sensor interlocks)

Installation & Maintenance Pitfalls (Expert Tips)

- Safety Wiring Must Follow PLe/SIL 3 Standards: A rookie tech at a power plant used non-shielded cable for safety interlocks, causing EMI-induced false trips. Use double-insulated, shielded twisted-pair cable (22AWG minimum) for safety I/O, and separate from power cables by ≥30cm.

- Firmware Mismatch Breaks Safety Compliance: At an Ohio refinery, mixing 3HNM08868-1 firmware v2.1 with SafeMove 2 v3.0 caused safety logic errors. Always ensure module firmware (v3.5+ recommended) matches SafeMove software version—verify via RobotStudio.

- Hot-Swap Requires Safety Shutdown: Never swap the module while the robot is in auto mode. A rushed swap at a Michigan automotive plant triggered a safety fault, halting production for 2 hours. Procedure: 1) Put robot in manual mode, 2) Disable SafeMove via LHMI, 3) Wait for “safe to remove” LED, 4) Swap module and re-enable safety.

- ESD Damage Is Preventable: A technician at a Florida chemical plant handled the module without an ESD wrist strap, frying the safety logic chip. Always ground yourself to the IRC5 cabinet chassis and store the module in anti-static packaging.

- Safety Zone Configuration Is Mandatory: Skipping zone setup at a Texas power plant allowed the robot to enter a high-voltage area. Use SafeMove Configurator to define safety zones, safe speeds (≤250mm/s for collaborative tasks), and interlock logic—test all zones with a safety tester before commissioning.

- Diagnostic LEDs Are Critical: Ignoring a blinking “FAULT” LED at a Pennsylvania refinery led to a safety gate interlock failure. Use RobotStudio to pull safety event logs—common faults include open circuits (safety inputs) and overcurrent (safety outputs).

ABB 3HNM08868-1

Technical Deep Dive & Overview

The 3HNM08868-1 is a core safety component of ABB’s SafeMove 2 system, designed to enforce functional safety in IRC5 robot cells. Unlike generic safety modules, it’s purpose-built for industrial robotics, with SIL 3/PL e compliance that eliminates regulatory risks in high-hazard environments.

Internally, it features a redundant safety PLC architecture (dual-core processing) that cross-validates safety logic to prevent single-point failures. The 16 safety I/O channels use galvanic isolation (2500VAC) to block EMI—critical in power plants and refineries with high electrical noise. Communication via FSoE (Failsafe over Ethernet) ensures fast, reliable data transfer between the module and IRC5 controller, with a response time of ≤1ms for emergency stop signals.

What makes it field-tough is its industrial-grade design: conformal-coated PCB to resist dust, oil mist, and chemical vapors; operating temperature range (-20°C to +60°C) that handles refinery/power plant thermal swings; and vibration tolerance up to 3g. The hot-swappable design minimizes downtime during maintenance, while built-in diagnostics log safety events with 1µs time-stamping for post-incident analysis.

For field teams, its value lies in seamless integration with SafeMove 2 software—allowing configuration of safety zones, interlock logic, and safe motion profiles without custom coding. At a Midwestern power plant, retrofitting robot cells with 3HNM08868-1 eliminated 100% of safety-related downtime and ensured compliance with OSHA and IEC standards. In a Louisiana refinery, its redundant power and communication design prevented a safety system failure during a voltage surge, avoiding a potential incident.

This is the safety module you install when robot cell safety is non-negotiable—delivering the compliance, reliability, and durability needed to protect workers and equipment in the world’s most demanding industrial environments.