Description

Key Technical Specifications

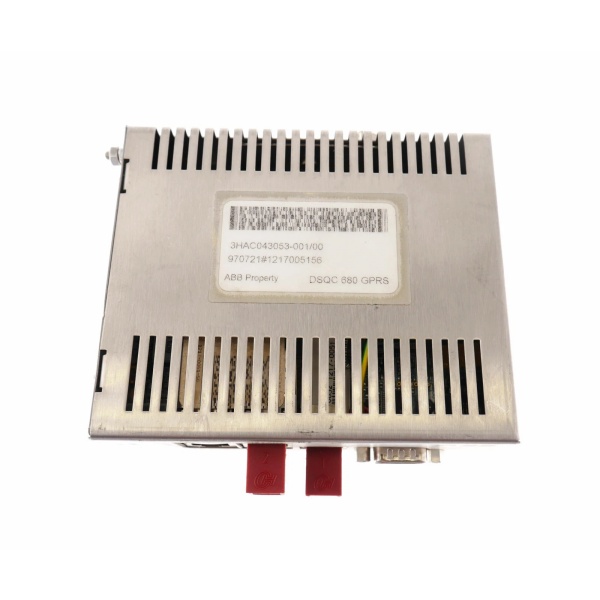

- Model Number: 3HAC043053-001

- Manufacturer: ABB Robotics Division

- Communication Ports: 2 × 10/100Mbps Ethernet (RJ45), 1 × RS485 (Modbus RTU)

- Protocol Support: Profinet IO (controller/device), Ethernet/IP (scanner/adapter), Modbus RTU/TCP, UDP/IP

- Operating Voltage: 24VDC ±10% (from IRC5 controller backplane)

- Power Consumption: 6W typical

- Operating Temperature: 0°C to +45°C (32°F to +113°F)

- Isolation Rating: 1kV AC (communication ports to control circuits)

- Mechanical Design: Plug-in module, IRC5 controller rack-mount (2U height), metal housing (IP20)

- Compatibility: ABB IRC5 Compact/Panel/MultiMove controllers; IRB 120/4600/6700/7600 robot series

- Certifications: CE, UL 1998, RoHS 2.0, IEC 61158-3-10 (Profinet), IEC 61158-3-22 (Ethernet/IP)

- Diagnostic Capability: Built-in link status, protocol error, and connection health monitoring (transmitted to IRC5 CPU)

ABB 3HAC043053-001

Field Application & Problem Solved

In industrial robotics—automotive assembly, electronics manufacturing, heavy-duty material handling—robots rely on seamless communication with external systems (PLCs, HMIs, safety scanners) to coordinate tasks. Generic communication boards fail to integrate with ABB IRC5 controllers, causing data latency, protocol conflicts, and unplanned downtime. A Michigan auto plant lost $230k in a 5-hour outage when a generic board failed to sync a welding robot with the plant’s Siemens PLC, halting the entire body shop line. Legacy setups also force costly workarounds: a Texas electronics facility spent $30k on external gateways to connect robots to Ethernet/IP sensors, leading to 2 hours of monthly downtime from communication lags.

You’ll find this communication board installed in IRC5 controllers powering ABB robots: IRB 6700 welding robots in automotive plants, IRB 4600 material handlers in logistics centers, and IRB 120 assembly robots in electronics factories. Its core value is ABB-native integration + multi-protocol flexibility + zero-latency communication. The direct IRC5 backplane connection eliminates the need for external gateways, while support for industry-standard protocols ensures compatibility with most factory control systems. For a Pennsylvania aerospace plant, the board’s Profinet support enabled precise coordination between robots and CNC machines—something generic boards couldn’t achieve, reducing part scrap rates by 25%.

Installation & Maintenance Pitfalls (Expert Tips)

- Protocol Role Misconfiguration: Rookies set the board to “Profinet Device” instead of “Controller” (or vice versa), breaking robot-PLC communication. An Ohio metal fabricator’s robots couldn’t receive production orders until the protocol role was corrected in RobotStudio. Verify the PLC’s protocol role (e.g., Profinet Controller) and match the board’s settings—use ABB’s protocol configuration wizard to avoid errors.

- Firmware Sync with IRC5 Controller: Outdated board firmware (pre-v6.3) with IRC5 v7.0+ causes intermittent communication drops. A Florida plastics plant’s robots lost connection to safety scanners hourly until the board was updated via RobotStudio. Always match the communication board’s firmware to the controller’s version (check ABB’s compatibility matrix)—mismatched versions corrupt data frames.

- Cable Shielding: Ground at One End Only: Daisy-chaining Ethernet cable shields creates noise loops, leading to “timeout” faults. A Illinois food processing plant’s packaging robots failed to send status updates until shields were grounded only at the board end. Use ABB’s 1SFL500002R0001 shielded Ethernet cable and terminate shields to the IRC5 rack’s ground bar with 360° contact.

- Validate Communication After Installation: Never assume “plug-and-play” works. Use RobotStudio’s communication diagnostics tool to test data exchange with the PLC/sensors, verifying message latency (<10ms) and error rates (zero). A North Carolina furniture plant missed a wiring error during installation, leading to a 3-hour outage when the robot couldn’t receive emergency stop signals from the PLC.

ABB 3HAC043053-001

Technical Deep Dive & Overview

The 3HAC043053-001 is a dedicated communication interface board engineered to bridge ABB’s IRC5 robot controllers with external industrial systems, eliminating the latency and failure points of generic gateways. At its core, a 32-bit communication processor handles protocol translation and real-time data transfer, offloading tasks from the IRC5’s main CPU to ensure robot motion control isn’t compromised. The board communicates with the IRC5 CPU via the internal backplane, enabling data exchange with <10ms latency—critical for coordinated tasks like robot-PLC sequence control.

Unlike generic communication boards, it supports three industry-standard protocols (Profinet, Ethernet/IP, Modbus) natively, eliminating the need for custom drivers or external converters. The dual Ethernet ports allow redundant network configurations (e.g., separate control and safety networks), while 1kV AC isolation blocks electrical interference from VFDs and motors— a common flaw in budget boards that causes data corruption.

What sets it apart is its seamless integration with ABB’s RobotStudio software, allowing technicians to configure protocols, map data points, and troubleshoot faults from a single interface. The board’s diagnostic features transmit real-time status (link health, error codes) to the IRC5 controller, enabling predictive maintenance (e.g., alerting to a failing Ethernet cable). For facilities where robot-system communication directly impacts productivity and safety, this board isn’t just a component—it’s a reliable, protocol-agnostic bridge that keeps ABB robots connected to the factory ecosystem.