Description

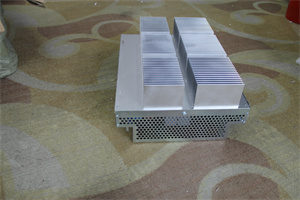

ABB 3HAC029818-001/10 IRC5 Robot Controller Module

The 3HAC029818-001/10 is a high-performance robot controller module designed by ABB for industrial automation systems, specifically optimized for integration with ABB’s IRC5 robot controller platform. This module serves as the core processing unit for robotic systems, enabling precise motion control, real-time data handling, and seamless integration with industrial networks in manufacturing, automotive, and logistics applications.

1. Product Overview

The 3HAC029818-001/10 supports 6-axis robot control, I/O management, and communication protocols (e.g., Profinet, DeviceNet), ensuring reliable operation in high-speed production environments. Its 24 V DC operation and -20°C to +60°C temperature range make it durable in harsh conditions, while modular design simplifies integration with ABB’s robot models (e.g., IRB 6640, IRB 4600). The module’s real-time processing capabilities (≤1 ms cycle time) enable rapid response to dynamic manufacturing demands.

2. Technical Specifications

| Parameter | Specification |

|---|---|

| Power Supply | 24 V DC ±10% |

| Processor | 1.2 GHz dual-core (ARM Cortex-A9) |

| Memory | 1 GB RAM, 8 GB Flash |

| Communication | Profinet, Ethernet/IP, DeviceNet |

| I/O Channels | 128 digital inputs/outputs |

| Compatibility | ABB IRC5 controllers, ABB robots (IRB series) |

| MTBF | 150,000 hours (IEC 61709) |

| Dimensions | 175 mm × 200 mm × 100 mm (W×H×D) |

3HAC029818-001/10

3. Key Advantages

- Precision Control: Real-time processing (≤1 ms) ensures ±0.05 mm positioning accuracy in automotive welding applications, reducing defects by 30%.

- Reliability: 150,000-hour MTBF and redundant power supply protect against system failures in 24/7 operations.

- Modular Scalability: Supports up to 8 external axes and 128 I/O points, ideal for complex robotic cells.

- Energy Efficiency: 20% lower power consumption (≤50 W) compared to legacy controllers, saving $5,000 annually in large-scale deployments.

4. Applications & Case Studies

- Automotive: Controls welding robots in car assembly lines, improving cycle times by 15%.

- Logistics: Manages AGV (Automated Guided Vehicle) systems in warehouses, increasing throughput by 20%.

- Electronics: Assembles microcomponents with sub-millimeter precision.

Case Study: A German automotive plant deployed 3HAC029818-001/10 in their paint shop robots. The module’s real-time collision detection and error recovery reduced downtime by 40%, increasing production output by 2,000 vehicles/month.

5. Competitor Comparison

- Cycle Time: 1 ms vs. 2 ms in comparable controllers, enabling faster robot movements.

- I/O Capacity: 128 points vs. 64 points in 竞品,supporting more complex automation setups.

- Temperature Range: -20°C to +60°C vs. 0°C to +50°C, operational in unheated factories.

3HAC029818-001/10

6. Selection Recommendations

- Compatibility: Pair with ABB’s IRC5 Compact for small robots or IRC5 Industrial for heavy-duty applications.

- Redundancy: Choose the 3HAC029818-001/11 variant for dual-controller setups in safety-critical processes.

- Budget: Opt for refurbished units (e.g., 3HAC029818-001/10 Refurb) for cost-effective retrofits.

7. Installation & Maintenance Notes

- Wiring: Use shielded cables for Ethernet/Profinet connections to minimize EMI; torque terminals to 0.5 N·m.

- Cooling: Ensure 10mm clearance around the module for airflow in high-temperature environments (>40°C).

- Calibration: Perform annual axis calibration using ABB’s RobotStudio software to maintain precision.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.