Description

Key Technical Specifications

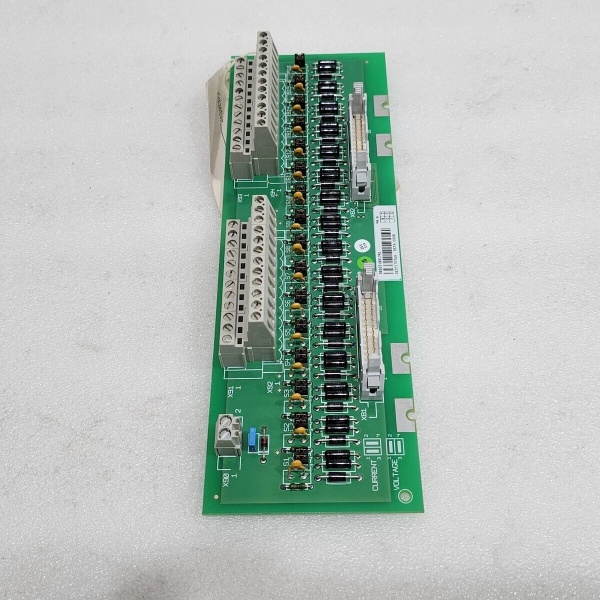

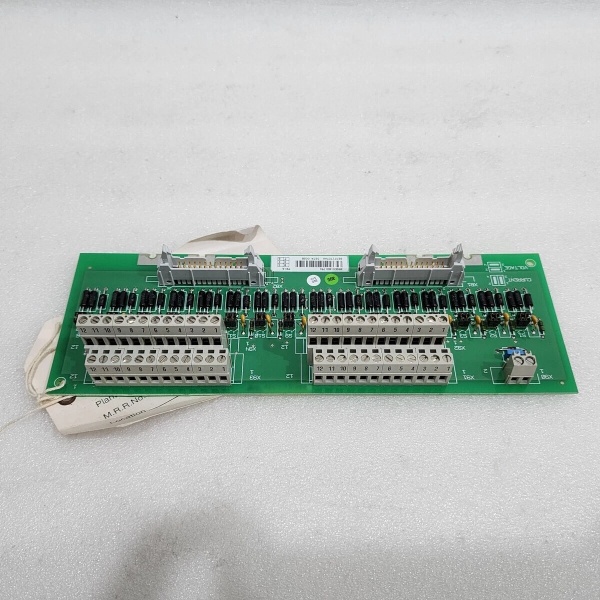

- Model Number: 3HAC027851-001

- Manufacturer: ABB Robotics Division

- Safety Certification: IEC 61508 (SIL 3), ISO 13849-1 (PL e)

- Safety Inputs: 8 dual-channel safety inputs (E-stop, door interlocks, safety scanners)

- Safety Outputs: 4 dual-channel safety outputs (robot motion enable, cell lockout)

- Operating Voltage: 24VDC ±10% (from IRC5 controller backplane)

- Power Consumption: 5W typical

- Operating Temperature: 0°C to +45°C (32°F to +113°F)

- Isolation Rating: 2kV AC (safety circuits to control circuits)

- Communication: Internal IRC5 backplane (safety data exchange with main CPU)

- Mechanical Design: Plug-in module, IRC5 controller rack-mount (2U height)

- Certifications: CE, UL 1998, RoHS 2.0

- Compatibility: ABB IRC5 Compact/Panel/MultiMove robot controllers

ABB DSTA002B 3BSE018317R1

Field Application & Problem Solved

In industrial robotics—automotive welding lines, electronics assembly, heavy machinery material handling—safety compliance and reliable interlock control are non-negotiable. Generic safety boards fail to integrate with ABB IRC5 controllers, leading to compliance violations and catastrophic accidents. A Michigan auto plant was fined $220k by OSHA after a generic safety board failed to stop a welding robot, injuring a technician. Legacy setups also suffer from communication lag: a Texas electronics facility experienced 3-second delays between door interlock triggers and robot shutdowns, risking collisions with operators.

You’ll find this safety board installed in IRC5 controllers powering ABB robots: IRB 6700 welding robots in automotive plants, IRB 120 assembly robots in electronics factories, and IRB 4600 material handlers in packaging facilities. Its core value is ABB-native integration + SIL 3 compliance + zero-latency safety response. The direct IRC5 backplane connection eliminates communication delays, while dual-channel inputs ensure fail-safe operation—critical for stopping 6-axis robots weighing up to 500kg. For a Pennsylvania aerospace plant, the ISO 13849-1 PL e certification ensured compliance with strict aviation safety standards, avoiding costly production halts.

Installation & Maintenance Pitfalls (Expert Tips)

- Dual-Channel Wiring Is Mandatory: Rookies wire safety inputs (e.g., E-stop) to single channels, voiding SIL 3 certification. A Florida plastics plant’s safety audit failed until technicians rewired all interlocks to dual channels. Follow ABB’s wiring diagram—each safety device must connect to both channels of an input pair to ensure fault detection.

- Firmware Sync with IRC5 Controller: Outdated board firmware (pre-v6.0) with IRC5 v7.0+ causes safety communication failures. A Ohio metal fabricator’s robots locked out randomly until the board was updated via RobotStudio software. Always match safety board firmware to the controller’s version (check ABB’s compatibility matrix).

- Ground Safety Circuits Separately: Sharing safety circuit grounds with robot power circuits introduces noise, leading to false interlock triggers. A Illinois food processing plant’s packaging robots shut down hourly until a dedicated 10mm² safety ground bar was installed. Keep safety grounds isolated from power grounds and ensure <1Ω ground resistance.

- Validate Safety Functions After Installation: Never skip functional testing. Use RobotStudio’s safety validation tool to simulate E-stop, door interlock, and safety scanner triggers, verifying robot shutdown within 100ms. A North Carolina furniture plant missed a wiring error during installation, leading to a near-miss when a robot failed to stop after a door was opened.

Technical Deep Dive & Overview

The 3HAC027851-001 is a dedicated safety interface board engineered to enforce safety interlocks for ABB IRC5-controlled robots, operating as a standalone safety PLC within the controller. At its core, a dual-core microprocessor executes safety logic in lockstep—each core runs identical code, and outputs are only enabled if both cores agree, ensuring fail-safe operation. The board monitors 8 dual-channel safety inputs, designed to detect open circuits, short circuits, and cross-wiring in interlock devices like E-stops and safety doors.

Unlike generic safety boards, it communicates directly with the IRC5’s main CPU via the internal backplane, eliminating latency from external wiring or protocol translation. When a safety input is triggered (e.g., E-stop pressed), the board sends an immediate shutdown signal to the robot’s drive module, cutting motor power within 100ms—fast enough to stop a robot moving at 2m/s before it can travel more than 20cm. The dual-channel output design ensures that a single channel failure won’t prevent a safety shutdown, a critical feature for SIL 3 compliance.

What sets it apart is its seamless integration with ABB’s RobotStudio software, allowing technicians to configure safety logic, monitor inputs/outputs, and run diagnostics without external tools. For facilities where robot safety directly impacts operator well-being and compliance, this board isn’t just a component—it’s a life-saving, audit-proof solution built to work flawlessly with ABB’s industrial robot ecosystem.