Description

Key Technical Specifications

-

Model Number: 3HAC026611-001

-

Manufacturer: ABB Robotics

-

I/O Configuration: 16 DI (24VDC, sinking/sourcing), 16 DO (24VDC, 0.5A per channel, 4A total per module)

-

Isolation Rating: 500V AC (channel-to-channel), 1kV AC (I/O to backplane)

-

Response Time: ≤1ms (DI/DO signal latency)

-

Communication Interface: IRC5 controller backplane (proprietary robot bus)

-

Power Supply: 24VDC ±10% (derived from IRC5 controller, 0.3A typical current draw)

-

Operating Temperature: 0°C to +45°C (32°F to 113°F); derate 10% above 40°C

-

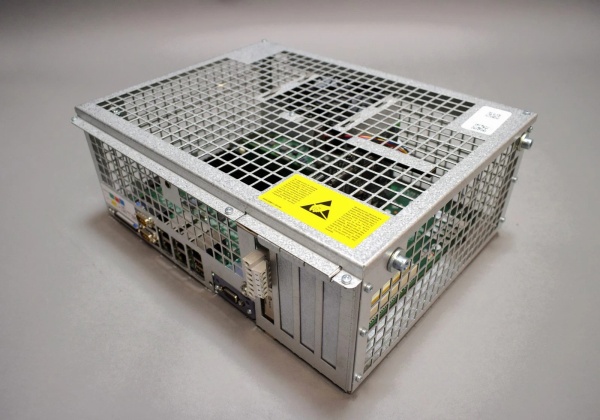

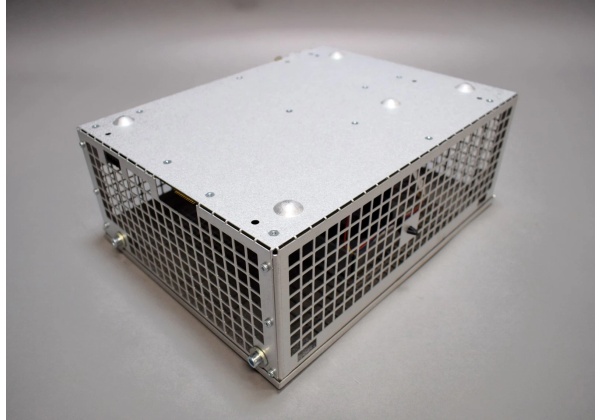

Physical Design: Rack-mount (fits IRC5 controller cabinet), 19-inch width, IP20 protection

-

Configuration Software: ABB RobotStudio

-

Protection Functions: Short-circuit protection on DO channels, over-temperature protection

-

Certifications: CE, UL 1012, IEC 61131-2

ABB 3HAC026611-001

Field Application & Problem Solved

In automotive welding lines and electronics assembly cells, the biggest robot integration headache is reliable communication between the robot and peripherals. Legacy discrete wiring (running 32+ individual wires from grippers/sensors to the controller) is messy, prone to short circuits, and impossible to troubleshoot quickly. I once saw a Michigan auto plant lose 3 hours of production because a frayed wire from a welding torch sensor caused a false “gripper open” signal—they had to trace 40+ wires to find the issue.

You’ll find the 3HAC026611-001 plugged into IRC5 controller racks, acting as the “translation hub” between ABB robots and factory floor devices: it takes signals from photoelectric sensors (e.g., “part present”) and sends commands to gripper solenoids or conveyor motors. Its core value is consolidated, isolated I/O: 32 signals run through a single backplane connection instead of dozens of wires, cutting wiring time by 70% and eliminating most wire-trace faults. At a Tennessee EV battery plant, retrofitting old discrete wiring with this module reduced peripheral-related robot downtime by 85%—the “part missing” false alarms that plagued them vanished overnight.

Another critical solve is its hot-swappable design. In 24/7 packaging lines, you can’t shut down the IRC5 controller to replace a faulty I/O module—that costs $1k+ per hour in downtime. This module lets you pull the failed unit and plug in a replacement while the robot is idle (between cycles), with zero need to rewire or reconfigure. At a North Carolina food packaging plant, we swapped a faulty module in 2 minutes during a product changeover—avoiding a 2-hour shutdown.

Installation & Maintenance Pitfalls (Expert Tips)

DO Channel Loading Must Stay Below Limits

Rookies daisy-chain too many devices (e.g., 4 gripper solenoids) on a single DO channel, exceeding the 0.5A per-channel limit. This triggers short-circuit protection, shutting down the channel and causing “output fault” alarms. Calculate total current draw for each device (e.g., a 24V solenoid draws ~0.2A) and limit each channel to 2 devices max. A Ohio welding cell had a DO channel fail daily until we split 4 solenoids across 2 channels—post-fix, it ran fault-free for 6 months.

DI Signal Polarity (Sinking/Sourcing) Is Critical

The module supports both sinking (NPN) and sourcing (PNP) DI signals, but technicians often mix them without reconfiguring the module. A sourcing sensor connected to a sinking-configured DI won’t send a “high” signal, leading to “part not detected” false faults. Use RobotStudio to set each DI group to sinking or sourcing, and match the sensor type to the configuration. I fixed a Kentucky electronics plant’s robot in 15 minutes—they’d plugged PNP sensors into sinking DI channels.

Backplane Connector Cleaning Prevents Intermittent Faults

The module’s backplane connector collects dust and oil mist over time, causing intermittent “I/O communication lost” alarms. During quarterly PMs, remove the module and clean the connector pins with a dry microfiber cloth (never use alcohol—it degrades the pin coating). A Indiana foundry’s robot had random shutdowns until we cleaned the connector—they’d ignored it for 2 years, blaming “robot software glitches.”

Wire Termination Torque Saves Headaches

Under-tightened terminal screws cause intermittent signal drops—one of the hardest faults to diagnose. The module’s terminals require 0.5 N·m torque (use a calibrated torque screwdriver). Over-tightening strips the threads; under-tightening creates resistance that mimics “sensor failure.” I spent 4 hours chasing a “gripper not closing” fault that turned out to be an under-tightened DO terminal—don’t skip this step during commissioning.

ABB 3HAC026611-001

Technical Deep Dive & Overview

The 3HAC026611-001 is a digital I/O module engineered exclusively for ABB’s IRC5 robot controllers, designed to simplify robot-peripheral integration. At its core, a dedicated microcontroller manages all I/O signals, converting discrete sensor/actuator signals into the IRC5 backplane protocol for communication with the robot’s main CPU. This offloads I/O processing from the CPU, keeping robot motion control responsive—critical for high-speed applications like pick-and-place.

Each DI channel uses optocoupler isolation to block EMI from welding transformers or motor drives—this is why it’s far more reliable than discrete wiring. The DO channels feature solid-state relays (SSRs) instead of mechanical relays, eliminating contact wear and extending the module’s life to 10+ years. When a DO channel detects a short circuit (current >0.6A), it automatically shuts off power to the channel and sends a fault code to RobotStudio, letting technicians pinpoint the issue without a multimeter.

Configuration is done via RobotStudio: you map DI/DO channels to robot I/O signals (e.g., DI1 = “part present,” DO1 = “gripper close”), set sinking/sourcing modes, and enable fault detection. The module’s compact rack-mount design fits 8+ units in a single IRC5 cabinet, supporting large-scale integration (e.g., a robot with 4 grippers and 12 sensors). Built with conformal-coated circuit boards to resist oil, dust, and coolant in manufacturing environments, it’s the unsung hero of reliable robot operation.