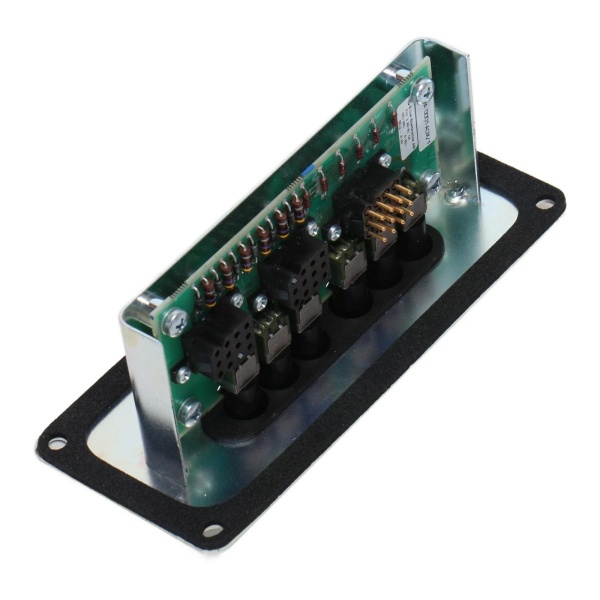

Description

Key Technical Specifications

-

Model Number: 3HAA0001-AA

-

Manufacturer: ABB

-

Material: High-strength aluminum alloy, anodized

-

Function: Axis-4 structural housing & cooling interface

-

Surface Finish: Ra0.8 precision machined, anodized hard-coat

-

Cooling: Internal channel for air or liquid (customer option)

-

Sealing: IP54 when assembled with O-rings

-

Operating Temp: −20 °C to +80 °C continuous

-

Weight: ≈0.45 kg

-

Mounting: Two dowel pins + M6 through-holes

-

RoHS: Compliant

ABB 3HAA0001-AA

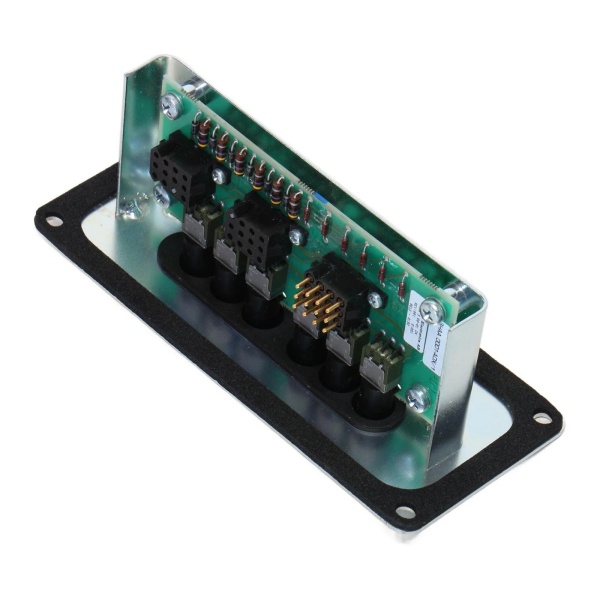

Field Application & Problem Solved

In the field, the biggest headache on older IRB arms is axis-4 overheating during high-speed welding or dispensing. The motor sits inside a nearly sealed wrist—no airflow, no heat-sink. 3HAA0001-AA fixes that: it’s the only OEM housing that builds a cooling gallery right into the casting. You plumb shop-air or a 1/8” coolant line and the wrist temp drops 8-10 °C. That keeps the servo encoder from drifting and saves you a “motor over-temp” fault every other shift.

In the field, the biggest headache on older IRB arms is axis-4 overheating during high-speed welding or dispensing. The motor sits inside a nearly sealed wrist—no airflow, no heat-sink. 3HAA0001-AA fixes that: it’s the only OEM housing that builds a cooling gallery right into the casting. You plumb shop-air or a 1/8” coolant line and the wrist temp drops 8-10 °C. That keeps the servo encoder from drifting and saves you a “motor over-temp” fault every other shift.

You’ll see this housing on every IRB 6700/4600 that runs 24/7—auto body lines, white-goods welding, even foundry deburring. Its main value is structural (it’s the reference surface for the whole wrist) but the cooling channel is what keeps the motor alive past 15 000 h.

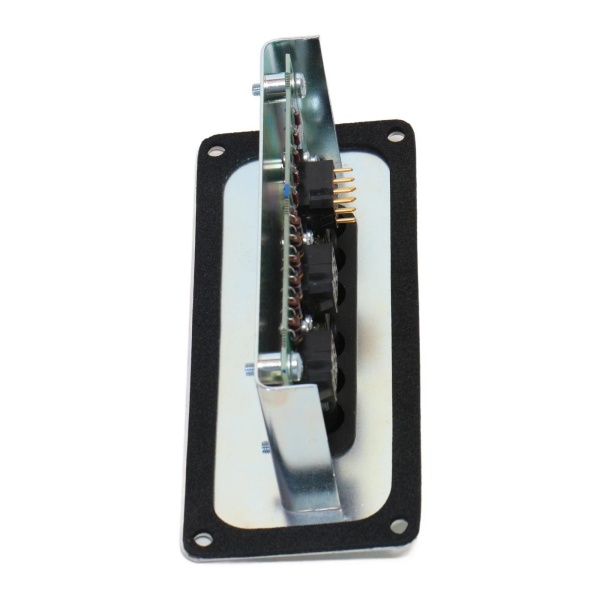

Installation & Maintenance Pitfalls (Expert Tips)

Dowel pins must be flush – If you hammer them in crooked, the wrist will bind on re-assembly. Use a driver, not a drift.

O-ring groove is shallow – One nick and you’ll spray coolant inside the motor. Lube the O-ring with silicone, don’t stretch it over sharp edges.

Torque pattern matters – M6 bolts should be 10 N·m diagonal sequence. Uneven torque warps the face and you’ll chase ±0.05 mm repeatability errors for weeks.

Coolant line orientation – The 1/8” BSPP port aims straight at the dress-pack. Rotate the housing 15° before you tighten, or you’ll kink the hose on the first axis-4 rotation.

ABB 3HAA0001-AA

Technical Deep Dive & Overview

3HAA0001-AA is a monolithic aluminum housing that doubles as the kinematic reference for axis-4. It carries the servo motor, the gear unit, and the customer dress-pack. The cooling gallery runs around the motor pocket—simple drilled circuit, but it works. ABB machines the motor bore and the gear-seat in one setup, so concentricity is <0.01 mm; that’s why you can’t swap in a generic housing and expect the robot to hold tolerance. The anodized surface gives you 1000 h salt-spray resistance—handy if your plant washes down with caustic. Bottom line: if axis-4 is running hot or you see wrist wobble, this housing is the first place to look.

3HAA0001-AA is a monolithic aluminum housing that doubles as the kinematic reference for axis-4. It carries the servo motor, the gear unit, and the customer dress-pack. The cooling gallery runs around the motor pocket—simple drilled circuit, but it works. ABB machines the motor bore and the gear-seat in one setup, so concentricity is <0.01 mm; that’s why you can’t swap in a generic housing and expect the robot to hold tolerance. The anodized surface gives you 1000 h salt-spray resistance—handy if your plant washes down with caustic. Bottom line: if axis-4 is running hot or you see wrist wobble, this housing is the first place to look.