Description

Key Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Model Number | ABB CI522A 3BSE018283R1 |

| Manufacturer | ABB |

| Product Type | Redundant communication interface module |

| Communication Protocol | AF100 protocol |

| Applicable System | S800 I/O system, compatible with System 800xA |

| Power Supply | 24V DC |

| Isolation Rating | 500V AC (channel-to-channel; channel-to-backplane) |

| Operating Temperature | -25°C to +70°C |

| Storage Temperature | Generally matches industrial module standards, around -40°C to +85°C |

| Protection Rating | IP20 |

| Weight | Approximately 0.2kg |

| Dimensions | 265mm×120mm×27mm (depth×width×height) |

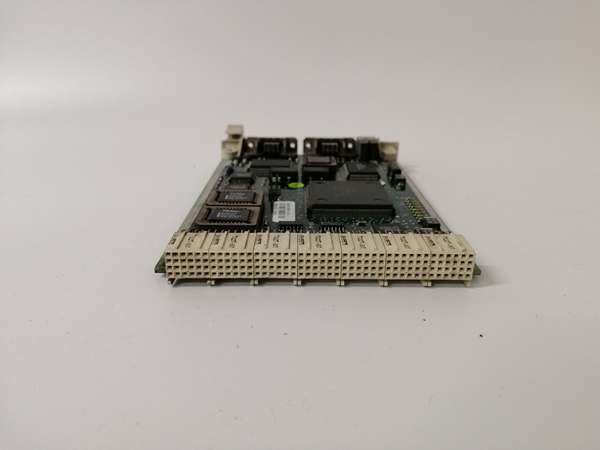

ABB CI522A 3BSE018283R1

Field Application & Problem Solved

In industrial automation scenarios such as chemical production lines and thermal power plant boiler control systems, once the communication between the S800 I/O system and the main control system is interrupted, it will lead to the loss of on-site data and the failure of control commands to be executed, resulting in production suspension or even safety accidents. For example, a chemical plant once had a communication line failure in the reactor temperature monitoring system. The traditional single communication module could not switch the communication path in time, resulting in a 4-hour shutdown and direct economic losses of hundreds of thousands of yuan.

The CI522A 3BSE018283R1 module solves this problem through its redundant communication design. It establishes a backup communication path for the S800 I/O system. When the main communication channel fails, it can seamlessly switch to the backup channel, ensuring the continuity of data transmission. In a thermal power plant’s steam turbine control system, after this module was adopted, the unplanned downtime caused by communication failures was reduced by more than 80%. In addition, it is compatible with multiple industrial control scenarios and can be applied to the data transmission of temperature, pressure, and flow sensors in pharmaceutical clean rooms, ensuring the stability of the production process and meeting the strict requirements of GMP certification.

Installation & Maintenance Pitfalls (Expert Tips)

- Match System Compatibility Before Installation: This module is specifically designed for the S800 I/O system. Many users mistakenly install it in non-matching I/O systems, resulting in incompatible communication. Before installation, confirm that the on-site control system is the S800 series, and check whether the System 800xA version matches to avoid communication failures caused by system mismatches.

- Ensure Correct Redundant Path Wiring: The core advantage of the module lies in redundant communication. Some construction personnel incorrectly connect the main and backup channels to the same line during wiring, making the redundant function invalid. When wiring, it is necessary to use two independent cables for the main and backup channels, and mark them clearly to ensure that the two paths are completely independent.

- Stabilize the Power Supply Voltage: The module relies on a 24V DC power supply. Voltage fluctuations exceeding ±20% will cause signal drift or module restart. It is recommended to configure a voltage stabilizer for the power supply circuit of the module, especially in power plants with large power grid fluctuations, to prevent communication interruptions caused by unstable power supply.

- Pay Attention to Isolation Protection During Wiring: The module has a 500V AC isolation rating. During installation, avoid parallel wiring with high-voltage cables. The distance between the module’s signal line and the high-voltage line should be more than 30cm to prevent electromagnetic interference from damaging the isolation performance and causing communication errors.

ABB CI522A 3BSE018283R1

Technical Deep Dive & Overview

The ABB CI522A 3BSE018283R1 is a core communication component in the S800 I/O series, mainly designed to solve the problem of reliable communication in industrial control systems. Its core lies in the AF100 protocol and redundant path design. The AF100 protocol has the advantage of stable transmission in industrial environments, which can ensure the accuracy and timeliness of data between the I/O system and the main control system. The redundant communication design is a key highlight. When the main communication channel fails due to line aging or external interference, the module can switch to the backup channel within milliseconds without manual operation.

In terms of hardware design, the module adopts a compact structure, with a weight of only 0.2kg and a small volume, which can save installation space in the control cabinet. The 500V AC isolation design between channels and between channels and the backplane can effectively prevent mutual interference between different signals and avoid module damage caused by voltage surges. At the same time, the IP20 protection level ensures that it can work stably in the indoor control cabinet environment, resisting dust and small particle pollution.

In practical application, this module can be seamlessly integrated into the System 800xA control platform. Engineers can monitor the module’s communication status in real time through the platform, and quickly locate problems such as channel faults. Its compatibility and scalability also allow it to be used in conjunction with various sensors and actuators, realizing the integrated transmission of on-site detection data and control signals. It is widely used in critical control links that require high reliability, such as chemical reaction kettle control and power generation unit monitoring, providing a solid guarantee for the continuous operation of industrial production.