Description

Key Technical Specifications

- Model Number: 3BHE041464R0101 UDD406A

- Manufacturer: ABB Industrial Automation Division (Drives Business Unit)

- Power Stage: 6-pack IGBT module (integrated freewheeling diodes)

- Voltage Rating: 650V DC link (compatible with 380-480V AC input)

- Output Current: 400A continuous, 600A peak (1 minute)

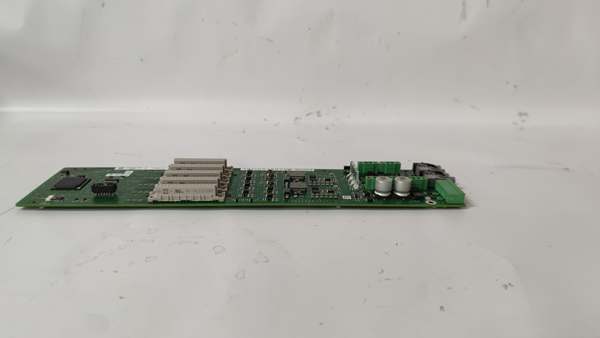

- Cooling Type: Liquid-cooled (glycol-water mixture, 5-60°C flow temperature)

- Operating Temperature: -10°C to +55°C (32°F to +131°F); derate 2% per °C above 45°C

- Isolation Rating: 2.5kV AC (power circuits to control circuits)

- Protection Features: IGBT desaturation protection, overtemperature, overvoltage, short-circuit, undervoltage lockout

- Mechanical Design: Bolt-on power stack, ACS800 drive chassis-compatible, metal housing (IP20)

- Certifications: CE, UL 508C, RoHS 2.0, IEC 61800-5-1

- Compatibility: ABB ACS800-07/09/11 VFD frames, heavy-duty industrial loads (50-200kW)

- Weight: 7.8kg (17.2lbs)

- Firmware Compatibility: ACS800 drive firmware v4.0+

ABB 3BHE041464R0101 UDD406A

Field Application & Problem Solved

In heavy-duty industrial drives—refinery crude oil pumps, paper mill main drives, power plant forced draft fans—generic power modules fail to handle the high current and thermal stress of continuous operation. These units lack integration with ABB ACS800 drives, suffer from IGBT thermal runaway, and cause catastrophic VFD failures. A Texas refinery lost $280k in a 6-hour outage when a generic power stack’s IGBT failed, damaging an ACS800 drive and halting a 150kW crude transfer pump. Legacy replacements also struggle with cooling: a Wisconsin paper mill spent $35k annually replacing air-cooled generic modules that overheated during summer production peaks.

You’ll find this power module in ACS800 drives powering: refinery distillation column pumps, paper mill calender rolls, steel mill conveyor systems, and wastewater treatment plant aerators. Its core value is ABB-native integration + liquid-cooled thermal management + industrial ruggedness. The UDD406A is calibrated to ACS800 drive control boards, eliminating compatibility issues, while liquid cooling maintains IGBT temperatures below 125°C even at 100% load. For a Pennsylvania steel mill, the module’s 600A peak current handling prevented tripping during motor startup surges—something generic modules couldn’t do, reducing downtime by 80% for their heavy-load drives.

Installation & Maintenance Pitfalls (Expert Tips)

- IGBT Wiring Torque: 8Nm for Power Connections: Rookies under-torque DC link or motor terminals, causing arcing and IGBT damage. An Ohio metal fabricator’s UDD406A failed after 3 months due to loose DC connections—use a torque wrench to apply exactly 8Nm to copper terminals. Apply anti-oxidant paste to prevent corrosion in humid environments.

- Cooling System Maintenance: Monitor Flow & Quality: Inadequate coolant flow (below 5L/min) or contaminated glycol triggers overtemperature shutdowns. A Florida food processing plant’s drives tripped hourly until technicians cleaned clogged coolant filters and verified flow rate with ABB’s flow sensor (1SFL500005R0001). Test coolant conductivity quarterly—replace if above 100µS/cm to avoid electrolytic corrosion.

- Firmware Sync with ACS800 Drive: Outdated module firmware (pre-v4.0) causes current regulation errors with ACS800 v5.0+. A North Carolina refinery’s pump drive exhibited erratic speed until the UDD406A was updated via DriveStudio. Always match power module firmware to the drive’s control board—mismatched versions corrupt torque control data.

- Static Discharge Protection: Handle with Anti-Static Wristbands: IGBTs are ESD-sensitive—rookies handling modules without anti-static protection fry the gate circuitry. A Louisiana paper mill destroyed two units ($4,200 total) during installation. Store modules in anti-static bags and ground yourself before handling.

- Load Testing Post-Installation: Simulate Peak Loads: Rookies skip full-load testing, missing latent IGBT defects. A Michigan auto plant’s drive failed during production when it hit 350A—use DriveStudio’s load test function to simulate 110% of rated current. Monitor IGBT temperature via drive diagnostics (keep below 125°C).

ABB 3BHE041464R0101 UDD406A

Technical Deep Dive & Overview

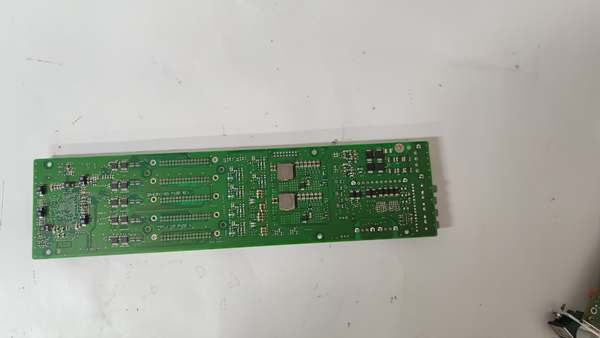

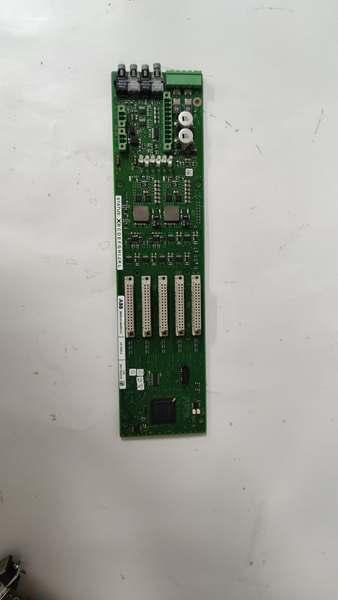

The ABB 3BHE041464R0101 UDD406A is a high-power IGBT module engineered to deliver stable power conversion for ABB’s ACS800 industrial drives. At its core, a 6-pack IGBT configuration converts 380-480V AC input to DC (via the drive’s rectifier) and back to variable-voltage, variable-frequency AC for motor control. The integrated freewheeling diodes protect IGBTs from voltage spikes during motor deceleration, a common failure point in generic modules.

Unlike generic power stacks, the UDD406A features ABB’s proprietary gate drive circuitry, which minimizes switching losses and prevents thermal runaway by adjusting gate voltage based on load conditions. The liquid-cooled design uses a dedicated heat sink and coolant channel to dissipate up to 15kW of power, enabling continuous operation at 400A—critical for 24/7 industrial processes. The module’s 2.5kV AC isolation blocks electrical interference from motor cables and VFD control circuits, ensuring reliable operation in noisy environments.

What sets it apart is its seamless integration with the ACS800 drive ecosystem: it bolts directly into the drive chassis and communicates with the control board via a dedicated interface, eliminating the need for custom wiring or tuning. The module’s rugged construction includes a conformal-coated PCB to resist dust and humidity, making it suitable for refineries, paper mills, and other harsh industrial settings. For facilities relying on heavy-duty drives, this power stack isn’t just a component—it’s a precision-engineered workhorse that delivers the reliability and performance needed to keep critical industrial processes running.