Description

Key Technical Specifications

- Model Number: 3BHE027632R0101

- Manufacturer: ABB

- Device Type: IGBT Power Stack Module (Integrated Three-Phase Bridge)

- Voltage Rating: 4500V DC link (continuous operating)

- Current Rating: 1200A rms (continuous), 3600A peak (surge)

- Semiconductor Type: High-voltage IGBT chips with anti-parallel free-wheeling diodes

- Operating Temperature: -25°C to +70°C (-13°F to +158°F)

- Storage Temperature: -40°C to +85°C (-40°F to +185°F)

- Isolation: 6kV AC (phase-to-phase, phase-to-chassis)

- Cooling Method: Liquid-cooled (ABB standard deionized water loop compatible)

- Control Interface: Integrated gate drive (±15V DC), fault feedback signals

- Dimensions (W x H x D): 320mm x 210mm x 105mm

- Weight: Approx. 5.8kg

- Protection Features: Over-temperature, over-current, short-circuit, and under-voltage protection

- Compliance: IEC 61972, IEC 60664-1, UL 1557, CSA C22.2

- Mounting: Bolt-on (compatible with ACS6000 drive cabinets, 35mm DIN rail adapter optional)

- Status Indicators: LED for power-on, gate drive active, and fault alerts

ABB 3BHE027632R0101

Field Application & Problem Solved

In heavy-industry settings—steel mills, mining operations, pulp mills, and refineries—the biggest challenge is powering large-scale motors (1MW+) with precise, efficient variable-frequency control. Legacy drives rely on thyristors that suffer from slow switching speeds, high energy losses, and limited control flexibility, leading to wasted energy and frequent maintenance. This IGBT power stack module solves that by combining high-voltage/current capacity with fast, efficient switching, bridging the gap between raw power and precise motor control.

You’ll typically find this module as a core component in ABB ACS6000 medium-voltage drives, powering critical equipment like steel mill rolling mill motors, mine hoist systems, pulp mill dryer section drives, and refinery compressor motors. It’s also a key retrofit component, replacing aging thyristor stacks in legacy drives to boost efficiency and reliability. In greenfield installations, it’s chosen for its scalability—multiple modules can be paralleled to support motors up to 100MW, eliminating the need for custom power solutions.

Its core value lies in efficiency and durability. The IGBT technology cuts conduction and switching losses by 30–40% compared to traditional thyristors, slashing energy costs for 24/7 operations. The integrated liquid cooling system ensures consistent thermal performance, even under full load, preventing the thermal cycling that degrades semiconductors. For plant operators, this translates to lower energy bills, fewer unplanned outages, and extended maintenance intervals—critical in industries where downtime costs $50k+ per hour.

Installation & Maintenance Pitfalls (Expert Tips)

Liquid Cooling Water Quality Is Non-Negotiable

Rookies often use tap water or improperly treated deionized water in the cooling loop. Contaminants or incorrect conductivity (above 10μS/cm) cause corrosion or scaling in the module’s cooling channels, blocking heat transfer and leading to over-temperature failures. Use only ABB-specified deionized water with a corrosion inhibitor, and test conductivity monthly. Flush the loop every 6 months to remove sediment—this extends the module’s lifespan by 50% or more.

Gate Drive Signal Wiring: Avoid EMI Interference

The integrated gate drive is sensitive to electromagnetic interference (EMI) from high-voltage power cables. Technicians frequently run gate drive wires parallel to power cables, causing signal distortion that leads to erratic switching or false faults. Maintain at least 30cm (12 inches) of separation between gate drive and power cables, and use double-shielded twisted-pair cable. Ground the outer shield at the drive controller end only—double-ended grounding creates ground loops that amplify noise.

Power Terminal Torque: Precision Prevents Arcing

Over-tightening or under-tightening the 1200A power terminals is a catastrophic error. Over-tightening (exceeding 25Nm) cracks the copper busbar or strips terminal threads, while under-tightening (below 20Nm) causes resistance heating and arcing. Use a calibrated torque wrench set to ABB’s spec (20–25Nm) and recheck after the first week of operation—thermal cycling loosens connections in high-load applications. Never use aluminum busbars; copper’s higher conductivity prevents hotspots.

Pre-Installation Insulation & Continuity Checks

Skipping insulation tests is a common mistake that leads to short circuits on power-up. Use a 5kV megohmmeter to test phase-to-phase and phase-to-chassis insulation—resistance must be ≥200MΩ. A lower reading indicates internal damage from shipping or handling. Also, check continuity of the free-wheeling diodes with a multimeter—open or shorted diodes mean the module is faulty. These checks take 15 minutes but prevent $10k+ in system damage.

ABB 3BHE027632R0101

Technical Deep Dive & Overview

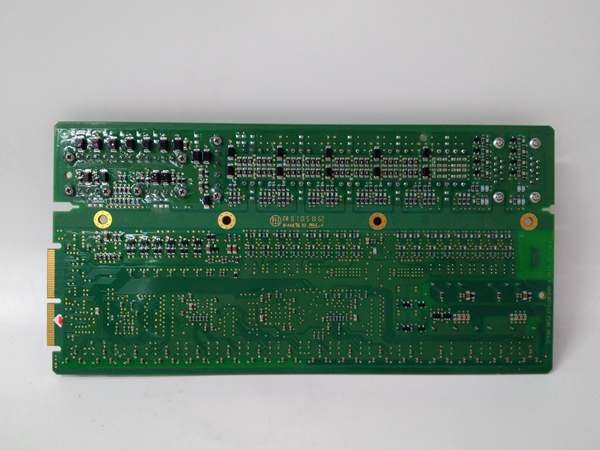

The ABB 3BHE027632R0101 is a high-performance IGBT power stack module, purpose-built for ABB’s ACS6000 medium-voltage drive series. It integrates a three-phase bridge configuration of high-voltage IGBT chips, anti-parallel free-wheeling diodes, integrated gate drives, and protection circuitry into a single rugged housing—consolidating critical power conversion functions to simplify installation and reduce failure points.

At its core, the module converts the drive’s DC link voltage (from the rectifier stage) into variable-frequency AC power for large motors. The IGBT chips switch at 2–5kHz, a balance that delivers precise motor speed control while minimizing switching losses. The anti-parallel free-wheeling diodes provide a path for inductive load currents during IGBT turn-off, preventing voltage spikes that would damage the semiconductors. The integrated gate drive ensures optimal IGBT switching performance, with built-in protection against over-voltage and over-current in the gate circuit.

The liquid cooling system is a cornerstone of its design: internal channels route deionized water directly across the IGBT and diode substrates, removing heat efficiently even at full load. This allows the module to operate at junction temperatures up to 150°C without de-rating, a key advantage over air-cooled modules in hot industrial environments. The 6kV insulation rating ensures safe operation in medium-voltage systems, while real-time protection circuits monitor current, temperature, and voltage—triggering shutdowns or alerts to prevent catastrophic failure.

Integration with ACS6000 drives is seamless via standardized backplane connections and gate drive interfaces. The status LEDs provide on-site technicians with instant visibility into module health, while fault signals are transmitted to the drive controller for remote monitoring and diagnostics. Its compact form factor (320mm x 210mm x 105mm) enables dense packing in drive cabinets, supporting parallel configurations for higher current ratings. Overall, this module is a rugged, efficient workhorse—engineered to handle the most demanding industrial drive applications, delivering reliable performance and lower total cost of ownership.