Description

Key Technical Specifications

- Model Number: ABB 3BHE022333R0101

- Manufacturer: ABB Power Automation Division

- Redundancy Configuration: 1+1 hot-standby (dual integrated power units with shared redundancy controller)

- Output Rating: 24VDC ±0.3%, 10A continuous per unit; 20A maximum combined load

- Input Voltage: 110/220V AC/DC ±15% (wide-range, switch-selectable)

- Protection Features: Short-circuit (auto-reset, 15A trip), overload (120% capacity shutdown), overtemperature (70°C cutoff), overvoltage (28V DC clamp)

- Failover Time: <5ms (automatic switch between active/standby units)

- Operating Temperature: -20°C to +65°C (-4°F to +149°F)

- Isolation Rating: 2.5kV AC (input to output); 1kV AC (unit-to-unit)

- Compatibility: ABB Symphony Plus controllers (PPC905AE101), I/O modules (AI835A, DI830), HMI 800

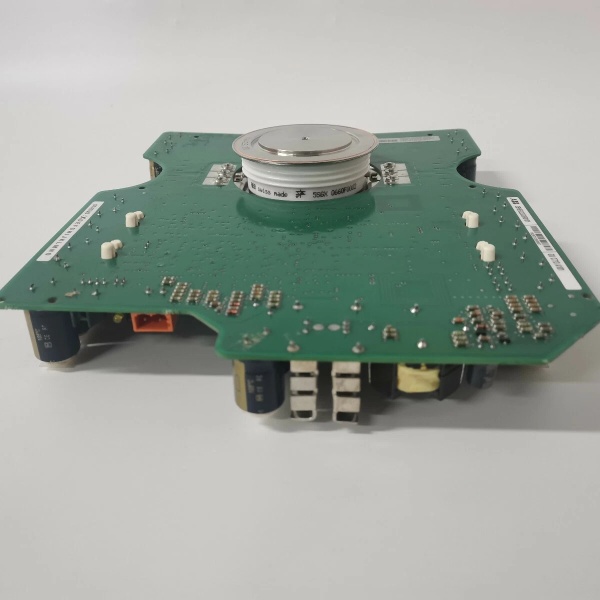

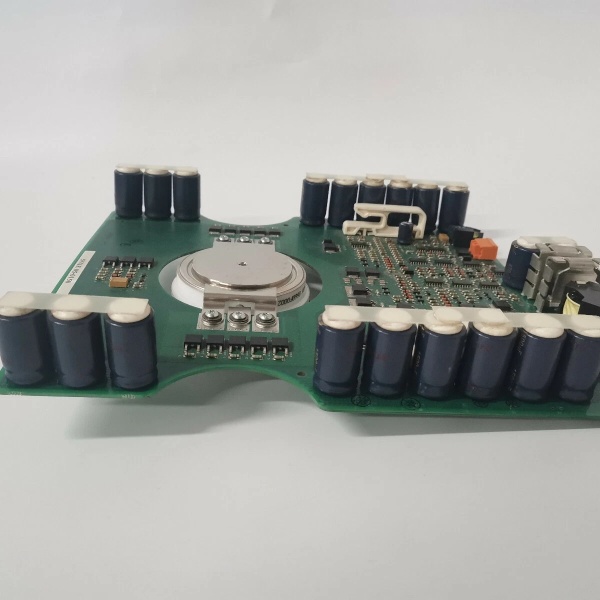

- Mechanical Design: Rack-mount (3U height), metal chassis, conformal-coated PCBs (IP20)

- Efficiency: ≥92% at full load; ≥88% at 20% load

- Certifications: IEC 61010-1, CE, UL 508, ATEX Zone 2, RoHS 2.0, IEC 61508 (SIL 2)

ABB 3BHE022333R0101

Field Application & Problem Solved

In critical power generation and petrochemical facilities—LNG plants, coal-fired power stations, and refineries—DCS power supply failures trigger catastrophic downtime. A 2023 outage at a European 600MW power plant cost $2.1 million in 10 hours when a non-redundant generic power module failed, cutting power to the Symphony Plus DCS and tripping the main turbine. Legacy power modules also struggle with harsh conditions: a Middle Eastern LNG facility’s generic units failed monthly due to extreme heat (55°C cabinet temps), costing 6 hours of downtime each for replacements.

You’ll find this module in Symphony Plus DCS racks powering mission-critical components: turbine control systems in Texas power plants, reactor safety loops in Louisiana refineries, and liquefaction train controllers in Qatar LNG facilities. Its core value is zero-unplanned-downtime redundancy plus extreme environmental ruggedness. The 1+1 hot-standby design fixed the European plant’s issue—when a voltage spike damaged one unit, the standby took over in 4ms, no process upset. At the Middle Eastern LNG facility, the module’s -20°C to +65°C operating range and high-efficiency design (minimizing heat output) eliminated monthly failures, extending service life to 7 years.

For a Southeast Asian petrochemical plant, the wide-range input (110/220V AC/DC) simplified a grid upgrade—no rewiring needed when switching from 110V to 220V. Its built-in overvoltage protection also prevented $180k in DCS component damage during a mains voltage spike (260V AC), a common issue in unstable power grids.

Installation & Maintenance Pitfalls (Expert Tips)

- Redundant Input Wiring—Separate Sources Are Non-Negotiable: Rookies wire both power units to the same AC circuit, defeating redundancy. A Texas refinery did this; a circuit breaker trip took down both units, triggering a 2-hour turbine shutdown. Feed Unit 1 from the plant’s main UPS, Unit 2 from the emergency backup UPS. Use ABB’s power monitoring relay (1SVR730700R0000) to alarm if either input drops below 90V AC/100V DC.

- Overloading Single Units Causes Premature Failure: Pushing 12A through one unit (exceeding the 10A rating) overheats the converter. A Pennsylvania chemical plant did this with a 15A I/O load, burning out the unit after 8 months. Distribute loads evenly (≤10A/unit) and use the module’s LED load indicators (green = normal, amber = 80% load, red = overload) to monitor. Add a 20A master fuse (ABB part 1SFA616001R1000) for the combined output as a backup.

- Heat Dissipation—Leave 100mm Clearance: Blocking airflow around the module’s vents causes overtemperature shutdown. A Wyoming coal plant stacked I/O modules directly above the 3BHE022333R0101; during summer, the module shut down daily at peak load. Create 100mm clearance above/below and avoid mounting near power-hungry components (e.g., VFDs). Use thermal imaging to verify case temps stay <60°C at full load.

- Quarterly Failover Testing—Don’t Wait for a Failure: Skipping testing hides latent redundancy controller faults. A German LNG plant ignored this; when a unit failed, the standby didn’t engage (faulty sync link), causing a 90-minute outage. Use ABB’s 3BSE048901R1 test tool to simulate a Unit 1 failure and verify standby takeover. Document results—regulators audit these records for critical safety systems.

ABB 3BHE022333R0101

Technical Deep Dive & Overview

The ABB 3BHE022333R0101 is a purpose-built redundant power supply for Symphony Plus DCS, engineered to deliver uninterrupted power to critical control systems. At its core, a dedicated redundancy controller manages load sharing and failover: under normal operation, each unit supplies 50% of the total load (≤10A/unit), reducing thermal stress and extending component life. If one unit detects a fault (input loss, overload, overtemperature), the controller shifts 100% of the load to the standby unit in <5ms—faster than the Symphony Plus CPU’s 20ms voltage dropout tolerance, ensuring no DCS shutdown.

Each power unit uses a high-efficiency switch-mode converter with power factor correction (PFC), minimizing input current draw and heat generation—critical for tight DCS cabinet spaces. The wide-range input (110/220V AC/DC) eliminates the need for external transformers, simplifying installation in global facilities. Protection mechanisms are layered: auto-reset short-circuit protection clamps current to 15A to prevent wire damage, while overtemperature shutdown (70°C) protects internal components from thermal degradation.

Ruggedization is tailored for harsh industrial environments: conformal-coated PCBs resist oil, dust, and chemical vapors (common in refineries and LNG plants), while the metal chassis shields against electromagnetic interference (EMI) from nearby motors or generators. The module communicates with the Symphony Plus DCS via the backplane, transmitting real-time status data (unit health, load, input voltage) and triggering alarms for faults—enabling remote monitoring and predictive maintenance.

What sets it apart from generic redundant power supplies is seamless Symphony Plus integration—no custom wiring or programming needed. Its SIL 2 certification ensures compliance with safety standards for critical control systems, while its 7-year service life (vs. 2-3 years for generics) reduces maintenance costs and downtime. For facilities where downtime costs $15k+ per minute, this module isn’t just a power supply—it’s a safety net that keeps critical processes running, even when one power unit fails.