Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | 3BHE021083R0101 XVC770BE101 |

| Manufacturer | ABB |

| Product Category | Vibration Monitoring Module |

| Input Channels | 16 channels (IEPE/Voltage) |

| Sampling Rate | Up to 102.4 kHz per channel |

| Signal Conditioning | ICP® power (2-20 mA), Anti-aliasing filters |

| Dynamic Range | 130 dB (24-bit ADC) |

| Communication | 2x Redundant Ethernet (IEEE 1588 PTPv2) |

| Protocol Support | OPC UA, MODBUS TCP, IEC 61850 |

| Operating Temp | -40°C to +85°C |

| Power Supply | 24 VDC (18–36 V) with reverse polarity protection |

| Certifications | SIL 2 (IEC 61508), ATEX/IECEx Zone 2 |

| Mounting | DIN rail (TS35) or panel |

| Housing Protection | IP40 (rack), IP20 (terminals) |

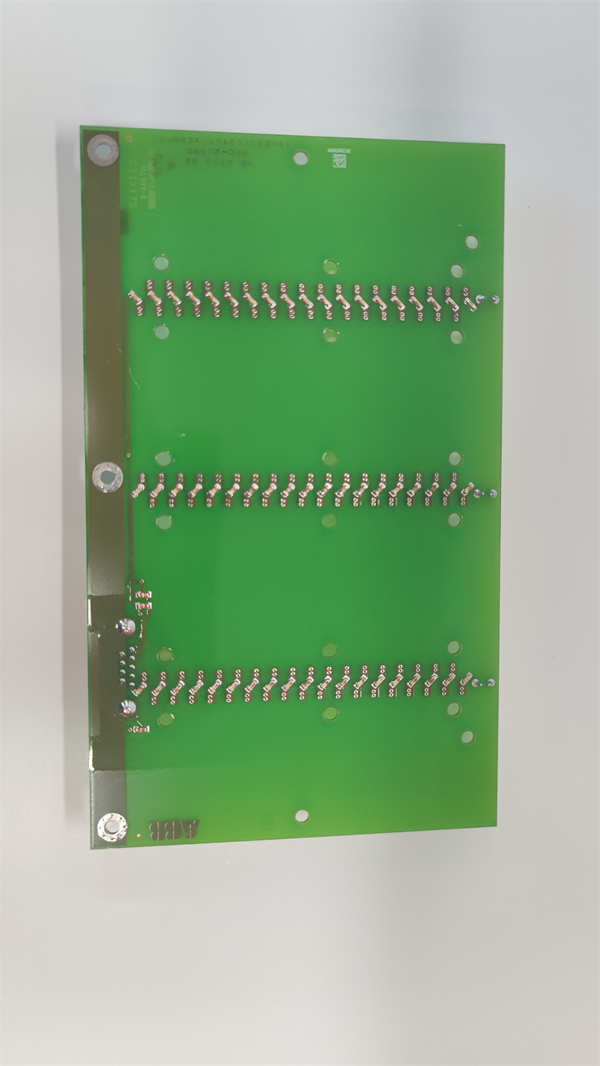

ABB 3BHE021083R0101 XVC770BE101

Product Introduction

The ABB 3BHE021083R0101 XVC770BE101 is an industrial-grade vibration monitoring module designed for ABB’s 800xA Distributed Control System (DCS). Engineered for critical machinery protection, this 16-channel module captures high-resolution vibration data from accelerometers and proximity probes, enabling real-time analysis of rotating equipment health. The ABB XVC770BE101 integrates seamlessly with ABB’s Condition Monitoring System (CMS), providing spectral analysis, time-waveform capture, and order tracking for predictive maintenance.

As a core component of ABB’s extended automation platform, this module supports phase-synchronized sampling across all channels – essential for torsional vibration analysis in turbines and compressors. Its dual-redundant Ethernet interfaces ensure continuous data streaming to control systems, while IEEE 1588 Precision Time Protocol (PTP) synchronizes measurements within ±500 ns across the network. For industries prioritizing asset reliability, the ABB 3BHE021083R0101 XVC770BE101 transforms raw vibration signals into actionable diagnostics.

Core Advantages and Technical Highlights

High-fidelity signal acquisition: 24-bit delta-sigma ADCs with 130 dB dynamic range capture subtle fault signatures (e.g., bearing spalls or misalignment) before catastrophic failures. Integrated IEPE constant current excitation (2–20 mA adjustable) supports industry-standard accelerometers without external power.

Synchronization excellence: Patented Multi-Channel Phase Lock technology maintains ±0.5° phase accuracy during shaft speed variations. Simultaneous sampling across all 16 channels eliminates skew errors in cross-channel analysis.

Cyber-resilient architecture: Hardware-enforced data integrity checks prevent spoofing. Secure boot with cryptographic signature validation meets IEC 62443-4-2 requirements.

Diagnostic intelligence: On-board FFT processing (up to 40,000 lines) with automatic peak detection. Tachometer inputs support order-based analysis and coast-down monitoring.

Typical Application Scenarios

In gas turbine power plants, the ABB 3BHE021083R0101 XVC770BE101 monitors blade-pass frequencies and combustion dynamics, triggering automatic load reduction when vibration exceeds ISO 10816 limits. Its sub-millisecond alarm latency meets API 670 requirements for machinery protection.

For offshore compressor stations, the module’s ATEX certification enables deployment in Zone 2 hazardous areas. High-frequency sampling (102.4 kHz) detects early-stage gearbox tooth defects in LNG liquefaction trains. Petrochemical plants leverage its torsional vibration analysis to prevent coupling failures in multi-motor drives.

Hydroelectric facilities use the module for draft tube vortex monitoring, with water pressure pulsation analysis via IEPE-powered transducers. Synchronized data from multiple units enables grid stability optimization.

Related Model Recommendations

3BHE021082R0101 XVC770AE101: 8-channel variant for compact installations

3BSE018741R1 CI854: Communication interface for PROFIBUS DP integration

3BHE024855R0101 XVC771BE101: SIL 3 certified version for safety-critical systems

3BSE008903R1 SD822: 32GB industrial SD card for waveform storage

3BSE016105R1 AI825: Analog input module for supplementary process signals

3BHE009681R0101 ZMU012: Signal conditioner for eddy current probes

3BHE039203R0101 TSP221: Turbine speed monitoring module

3BSE050091R25 PPC902AE: HMI panel for local diagnostics

ABB 3BHE021083R0101 XVC770BE101

Installation, Commissioning and Maintenance Instructions

Installation preparation: Mount the ABB XVC770BE101 vertically on DIN rail (TS35) with ≥100mm clearance above for ventilation. Use shielded twisted-pair cables (Belden 8761 or equivalent) for vibration signals, grounded at the DCS cabinet only. Verify sensor loop resistance <100Ω before power-up.

Maintenance suggestions: Perform monthly baseline spectrum captures via 800xA Condition Monitoring Manager. Replace terminal blocks every 5 years to maintain signal integrity. Calibration drift >1% requires sensor verification. For firmware updates, disable automatic switchover in redundant systems.

Service and Guarantee Commitment

ABB offers a 36-month warranty for the 3BHE021083R0101 XVC770BE101, including firmware updates and cybersecurity patches. Global technical support provides vibration analysis expertise through ABB’s Ability™ Collaborative Operations Centers. Lifetime product support guarantees spare parts availability for 15 years post-discontinuation. All modules undergo 500-hour accelerated life testing with sinusoidal vibration (10–500 Hz, 5 Grms) and thermal shock cycles. SIL certification includes TÜV SÜD validation reports.