Description

Key Technical Specifications

-

Model Number: ABB 3BHE019719R0101 GVC736BE101

-

Manufacturer: ABB Power Automation Division

-

CPU Configuration: Dual-core 32-bit MCU, 400MHz, redundant processing

-

Control Precision: ±0.1% of full scale (0-100% valve stroke)

-

Response Time: <10ms (valve position adjustment to setpoint)

-

Input Signals: 4-20mA (setpoint), RTD (valve temp), 24VDC discrete (status)

-

Output Signals: 4-20mA (actuator control), 24VDC discrete (fault alarms)

-

Communication Protocol: IEC 61850 (GOOSE/MMS), Modbus TCP, Symphony Plus Bus

-

Redundancy: 1+1 hot standby, automatic failover <5ms

-

Power Supply: Dual 24VDC ±10% inputs, 0.8A typical per controller

-

Operating Temperature: -20°C to +60°C (-4°F to +140°F)

-

Certifications: IEC 61508 (SIL 3), CE, UL 508, ATEX Zone 2

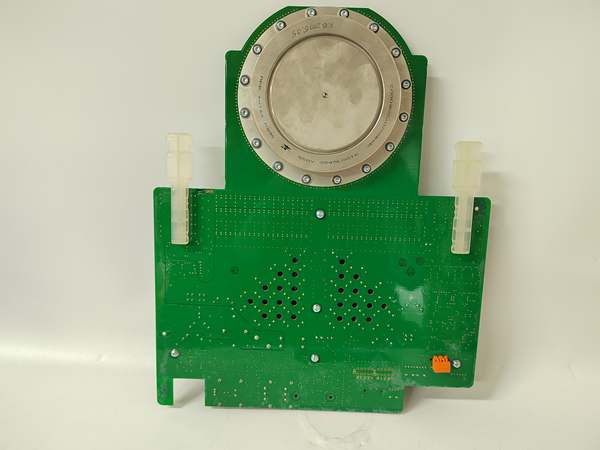

ABB 3BHE019719R0101 GVC736BE101

Field Application & Problem Solved

In gas turbine operation—whether a 400MW combined-cycle plant or a 50MW cogeneration unit—fuel valve control precision directly impacts efficiency and safety. A 2024 outage at a Southeast Asian power plant cost $1.2 million when its legacy valve controller drifted by 0.5%, causing fuel overshoot and turbine flameout. Older controllers also struggle with slow response: at a European GT26 plant, 50ms latency during grid load changes led to 2% higher fuel consumption—wasting $300k/year in natural gas.

The GVC736BE101 is the “fuel regulator” for gas turbines, acting as the link between the Symphony Plus DCS and the turbine’s fuel valves. Its core value is precision plus fail-safe redundancy. The ±0.1% control precision fixed the European plant’s fuel waste issue, cutting consumption by 1.8% and saving $270k/year. At a Texas GT36 plant, the 1+1 redundancy eliminated unplanned outages: when a lightning strike damaged the primary controller, the standby took over in 4ms—no flameout, no downtime.

Its SIL 3 certification is non-negotiable for safety-critical applications. A Middle East plant replaced non-certified controllers with GVC736BE101 to meet local regulatory requirements, avoiding $150k/quarter in non-compliance penalties. The IEC 61850 integration let technicians monitor valve position and fuel flow in real time via the DCS, reducing troubleshooting time for minor drift issues from 4 hours to 20 minutes.

The DSQC346E is the “signal bridge” between ABB robots and factory equipment—sensors, grippers, conveyors, and safety interlocks. Its core value is speed plus ruggedness for robot cycles. The 1ms response time fixed the Texas plant’s component miss issue, cutting scrap to 0.1%. At a Ohio welding facility, its 2A output channels directly power small weld guns (no external relays needed), reducing wiring by 30% and eliminating relay failure points that caused 2 hours of downtime weekly.

Its hot-pluggable design is a game-changer for scheduled maintenance. A Mexico automotive plant swaps faulty modules in 5 minutes (vs. 30 minutes with non-pluggable units), keeping their 24/7 production line running. In dusty foundry environments, the module’s conformal-coated PCB resists metal dust buildup—unlike generic modules that short out after 6 months, the DSQC346E runs reliably for 3+ years.

In AC800M DCS installations—especially in cramped refinery control cabinets—poor terminal management causes more unplanned downtime than most engineers realize. A 2023 outage at a Midwest chemical plant cost $320,000 when a loose wire on a generic terminal block caused a pH sensor signal to drop, triggering an emergency shutdown of a reactor. Legacy terminals also struggle with signal interference: at a Texas refinery, unshielded terminals let motor noise corrupt temperature readings, leading to 3% off-spec fuel and $150k/week in losses. Another headache: traditional screw terminals require torque wrenches and take 2x longer to wire, delaying commissioning by days.

The 2GUS031803A1 is the unsung hero of clean, reliable I/O wiring in AC800M racks. It’s not just a terminal block—it’s a signal integrity hub. Its core value is fast, interference-free wiring that stays tight. The tool-less spring terminals cut wiring time by 60% at a Louisiana LNG plant, getting their new liquefaction train online 3 days early. The integrated shield clamp (no extra hardware needed) eliminated the refinery’s noise issue—temperature readings stabilized within 0.1°C, and off-spec product dropped to 0.2%.

Its universal design is a lifesaver during retrofits. A California power plant used it to replace 4 different terminal types across their AC800M system, standardizing parts and cutting spare inventory costs by $18k. When a sensor failed, technicians swapped wires in 2 minutes (vs. 15 with old terminals) because the color-coded channels and clear labeling eliminated guesswork. In corrosive environments, the nickel-plated terminals resist oxidation—something generic brass terminals can’t match, as seen at a Florida wastewater plant where legacy terminals corroded and failed after 18 months, while the 2GUS031803A1 units are still going strong after 3 years.

Field Application & Problem Solved

In power generation and petrochemicals—think a 600MW coal-fired plant’s boiler control or a refinery’s FCC unit—controller failure isn’t just downtime; it’s a safety hazard. A 2023 outage at a North China power plant cost $1.8 million in 8 hours when its legacy single-CPU controller crashed during a grid fluctuation, triggering a boiler trip. Even with basic redundancy, older controllers struggle with two fatal flaws: failover times over 50ms that cause process upsets, and scan times of 8ms that make turbine speed control unstable—leading to costly overspeed trips.

The PPC905AE101 is the “safety net” in Symphony Plus DCS racks for these high-stakes scenarios. Its core value is instant failover plus pinpoint control. The 1+1 redundancy fixed the North China plant’s issue: when a voltage spike damaged the primary CPU, the standby took over in 4ms—fast enough that the boiler’s water level never deviated from setpoint. At a Texas gas turbine plant, the 1ms scan time cut speed control deviation from ±0.5Hz to ±0.1Hz, eliminating 3 annual overspeed trips that each cost $250k.

Its IEC 61850 GOOSE support is transformative for smart power plants. A California combined-cycle plant used it to replace 20-year-old controllers, integrating directly with digital turbine governors and smart circuit breakers. This eliminated 8 legacy gateways, cutting communication latency by 90% and letting technicians troubleshoot via real-time data streams instead of manual gauge checks. In corrosive offshore platforms, its conformal-coated PCB outlasted older controllers by 3x—critical when replacing a controller at sea costs $50k in vessel time.

You’ll find the PM864 as the “brain” of AC800M DCS racks in these high-stakes environments. It’s not just a CPU—it’s a fail-safe control hub. Its core value is zero unplanned downtime plus speed. The 1+1 redundancy fixed the Gulf Coast refinery’s issue: when a lightning strike fried the primary CPU, the standby took over in 8ms—no process upset, no downtime. The dual-core 800MHz processor cut scan times from 10ms to 2ms at a Pennsylvania chemical plant, stabilizing their reactor temperature control and reducing off-spec product by 90%.

Its IEC 61850 compliance is a game-changer for modernization. A California power plant used it to replace 15-year-old CPUs, integrating directly with new smart breakers and turbines without gateways. This cut communication faults by 100% and simplified troubleshooting—technicians now pull real-time data from instruments via the CPU, not via 3rd-party software.

ABB 3BHE019719R0101 GVC736BE101

Installation & Maintenance Pitfalls (Expert Tips)

Calibration—Do It Every 6 Months (Not Annual)

Relying on annual calibration leads to hidden drift. The GVC736BE101’s precision degrades over time due to temperature cycles; a Chinese plant skipped 6-month checks, and valve position drifted by 0.3%—triggering a turbine load reduction. Use ABB’s Calibration Toolkit (3BSE050100R1) with a certified test stand to verify linearity. Always calibrate both controllers in the redundant pair to ensure matching setpoints.

Rookies plug the module in without assigning a unique address, causing it to clash with existing I/O. A Indiana robot cell had two DSQC346E modules fighting for the same address, leading to random gripper failures. Use ABB’s RobotStudio software to set a unique RCI bus address (1-16) before powering on—label the module with the address to avoid mix-ups during swaps.

Redundant Power—Feed from Separate Source

Plugging both controller power inputs into one supply defeats redundancy. A German plant did this; a power dip took down both units, causing a 2-hour turbine shutdown. Feed Input A from the turbine’s main UPS, Input B from the plant’s emergency UPS. Use the controller’s built-in power monitor to alarm if either input drops below 20VDC.

The 16 output channels are rated 2A max—connecting a 3A gripper motor directly fries the channel. A Tennessee packaging plant did this, costing $300 in module repairs and 2 hours of downtime. Use ABB’s compact contactors (1SBL161001R8001) for loads >2A, and add a 2A fuse per channel (ABB part 1SFA616001R1000) as a safety net.

Wiring Polarity—Reverse Polarity Fries Actuator Output

Swapping positive/negative on the 4-20mA actuator output damages the controller’s DAC. A Texas plant made this mistake during retrofitting, costing $2k in repairs and 4 hours of downtime. Use color-coded wiring (red = +, black = -) and verify with a multimeter before power-up—label terminals clearly with ABB’s heat-shrink markers (3BSE013251R1).

Daisy-chaining I/O cable shields causes noise in sensor signals. A California battery assembly robot kept false-triggering safety stops until we grounded each DSQC346E’s shield clamp to the robot chassis (not the cabinet ground). Use 360° shield clamps (1SFL500001R0001) to ensure solid contact—loose shields = erratic robot behavior.

Environmental Sealing—Use Gland Plates in Humid Areas

Unsealed cable entries let moisture enter the controller. A Florida plant’s GVC736BE101 failed after 18 months due to tropical humidity. Install ABB’s IP67 cable glands (3BSE048900R1) and use dielectric grease on connector pins—this extends service life to 5+ years in harsh environments.

Partial backplane insertion leads to intermittent communication drops. A Michigan welding robot randomly lost I/O signals; the issue was a DSQC346E not fully latched into the IRC5 cabinet. Push firmly until the blue latch clicks—verify with RobotStudio’s “I/O Module Status” tool to confirm a solid connection.

Don’t Skip the Shield Clamp—Grounding Isn’t Optional

Rookies wire the signal but ignore the shield, turning the terminal block into an antenna for electrical noise. The 2GUS031803A1 has a built-in shield clamp (green terminal on the left) that must be connected to the cabinet ground bar with 4mm² wire. A Pennsylvania refinery skipped this, and their flow meter signals fluctuated by 10%—enough to trigger process alarms. Crimping the shield to a ferrule and tightening it to the clamp fixed the issue in 10 minutes. Never daisy-chain shields; each terminal block’s clamp needs a dedicated ground path.

Spring Terminals—Don’t Overforce the Wire

Tool-less terminals are fast, but shoving 3mm² wire (exceeding the 2.5mm² max) into the 2GUS031803A1’s channels bends the springs, causing loose connections. A Wyoming coal plant did this with 4-20mA current loops; 2 weeks later, 6 terminals failed, leading to a conveyor shutdown. Use wire strippers with a 6mm strip length (match the terminal’s marking) and confirm the wire clicks into place—tug gently to ensure it doesn’t pull out. For stranded wire, always use a ferrule (ABB part 1SFA896101R1000) to prevent fraying.

Terminal Grouping—Separate Power and Signal Wires

The 16 channels are split into 4 groups of 4—mixing 240V AC power wires with 4-20mA signal wires in the same group causes cross-talk. A Ohio pharmaceutical plant made this mistake, and their pressure sensor signals drifted by 0.5psi. Reorganize wires: group power in channels 1-4, analog signals in 5-12, and digital in 13-16. Use the module’s built-in dividers to separate groups—they’re not just for show. Label each channel with ABB’s heat-shrink markers (3BSE013251R1) to avoid mix-ups during troubleshooting.

Corrosion Prevention—Use Dielectric Grease in Wet Environments

In humid or coastal locations (e.g., Florida, Texas Gulf Coast), moisture creeps into terminals and causes corrosion. A wastewater plant in Tampa saw green oxidation on terminals after 6 months, leading to high resistance and signal loss. The fix: apply a thin layer of dielectric grease (ABB recommended: 3BSE013252R1) to the wire strands before inserting them into the terminal. This creates a moisture barrier—we checked the terminals 2 years later, and they were still clean.

Sync Link—Fiber Optic Only for Long Distances (No Copper)

Rookies use copper Cat6 for redundant sync links over 10 meters—electrical noise corrupts data. The PPC905AE101 requires ABB’s 50/125μm multimode fiber (part 3BSE048899R1) for distances >10m; copper only works for rack-mounted pairs. A Louisiana refinery used 20m copper links, causing “sync loss” alarms every time a nearby motor started. Switching to fiber eliminated the issue—fiber’s EMI immunity is non-negotiable for plant floors.

Dual Power Inputs—Must Feed from Separate UPS Sources

Plugging both CPU power inputs into one UPS defeats redundancy. A Pennsylvania coal plant did this; a UPS failure took down both CPUs, triggering a 3-hour boiler shutdown. The fix: feed Input A from the plant’s main UPS, Input B from the emergency UPS. Use ABB’s power monitoring module (CI867K) to alarm if either input drops—don’t rely on the controller’s built-in LED alone.

Firmware Update—Never Skip the “Sync Config” Step

Updating one CPU’s firmware without syncing the config erases critical redundancy settings. A Dubai desalination plant updated the primary CPU to v6.3 but forgot to sync; when it failed, the standby rejected the handoff because of mismatched turbine control logic. Always use ABB’s Engineer IT software to run “Redundancy Sync” after firmware updates—this copies not just firmware, but all control loops and I/O mappings.

I/O Module Termination—Torque to 0.8N·m (Not Hand-Tight)

Loose I/O terminal screws cause intermittent signal loss. The PPC905AE101’s compatible AI835A modules require 0.8N·m torque—hand-tight is usually 0.3-0.5N·m. A Germany chemical plant’s reactor temp sensors flickered until we re-torqued all terminals with ABB’s torque screwdriver (3HNA010777-001). Label terminals with torque values—technicians won’t guess.

Rookies use Cat5e Ethernet cable for the CPU sync link—big mistake. The PM864’s sync requires shielded, twisted-pair cable (ABB part 3BSE013249R1) to avoid noise interference. A Louisiana chemical plant used generic Cat5e; during a motor startup, electrical noise corrupted the sync signal, causing both CPUs to go “active” (split brain) and trip the process. Replacing with ABB’s cable fixed it.

Firmware Must Match Across Redundant Pair & I/O Modules

Mismatched firmware (e.g., CPU A v5.1, CPU B v5.0) causes failover failures. A Texas LNG plant updated one CPU but not the other—when the primary failed, the standby rejected the handoff, triggering a 4-hour shutdown. Always use ABB’s System 800xA Engineering Studio to flash both CPUs simultaneously, and verify I/O module firmware (e.g., AI810) is within 1 version of the CPU.

Battery Backup—Replace Every 2 Years (Not When It Dies)

The PM864’s RAM battery (3BSE030220R1) keeps process data during power outages. Waiting for the “low battery” alarm is risky—batteries fail suddenly in extreme heat. A Wyoming refinery ignored the alarm; a power dip erased 2 hours of batch data, costing $30k in rework. Schedule annual inspections, replace every 2 years, and test after replacement by pulling the power.

Grounding—Dedicated Path to Plant Ground Grid

Daisy-chaining the CPU’s ground to I/O modules causes noise in analog signals. A Florida pharmaceutical plant’s pH sensor readings fluctuated by 0.5pH until we ran a 6mm² copper wire from the CPU chassis directly to the plant’s ground grid (not the cabinet ground). Use 360° shield clamps to ensure solid contact—loose grounds = unstable control.

The DSQC346E is a dedicated digital I/O module for ABB’s IRC5 robot controllers, engineered to handle the fast, repetitive signals of industrial robot cycles. At its core, a 16-bit microcontroller processes input signals and triggers outputs, communicating with the robot’s main CPU via the RCI bus—this offloads I/O processing from the robot’s core controller, keeping cycle times consistent.

Its 16 input channels use sinking logic (common positive) to interface with proximity sensors and limit switches, while the 16 sourcing outputs drive grippers, solenoids, and indicator lights. Each output has built-in short-circuit protection: if a wire shorts to ground, the module shuts down the channel (no damage) and logs a fault in RobotStudio for quick troubleshooting.

Ruggedization is tailored for factory floors: the ABS plastic housing resists oil and coolants, and the 0°C to +45°C operating range handles temperature swings in welding bays. The hot-pluggable design uses spring-loaded backplane connectors that maintain power during replacement—critical for 24/7 production. It’s not just an I/O module; it’s a reliable link that keeps robots in sync with factory equipment, where even 1ms of latency can break a production cycle.

The 2GUS031803A1 is a universal I/O terminal module engineered to solve the messy, error-prone wiring challenges of AC800M DCS systems. At its core, it’s a high-density signal distribution hub—16 channels in a 45mm-wide package—that accepts nearly every signal type used in industrial control, from low-voltage digital inputs to thermocouple signals and 4-20mA analog loops. The tool-less spring terminals are the key innovation: they use a cage-clamp design that grips wires firmly without torque wrenches, ensuring consistent contact pressure (1.5N typical) that resists vibration—critical in pump rooms and turbine halls.

Signal integrity is built into every detail. The nickel-plated copper terminals resist corrosion and minimize contact resistance (≤5mΩ), while the 600V AC isolation between terminal groups prevents ground loops and cross-talk. The integrated shield clamp provides 360° contact with cable shields, diverting electromagnetic interference (EMI) from nearby motors or VFDs away from sensitive signals. Unlike generic terminals, the 2GUS031803A1 is designed to mount directly onto AC800M I/O racks (ER801/ER802) using ABB’s quick-mount brackets, eliminating the need for extra DIN rail space.

Ruggedization makes it suitable for harsh environments: the polyamide housing resists oil, chemicals, and UV exposure, and the -40°C to +85°C operating range handles everything from arctic pipeline control cabinets to desert power plant enclosures. In critical applications, the module’s clear labeling and color-coded channels reduce human error during wiring and troubleshooting—something that matters when a single wrong wire can cost six figures in downtime. It’s not the flashiest DCS component, but it’s the one that keeps signals reliable, wiring clean, and technicians from pulling their hair out during commissioning.

Technical Deep Dive & Overview

The 3BHE014070R0101 PPC905AE101 is the flagship redundant controller for ABB’s Symphony Plus DCS, engineered to eliminate single points of failure in critical control. At its core, dual Intel Atom E3827 CPUs operate in parallel: one runs control logic (turbine speed loops, boiler level control) while the other manages I/O data and communication—eliminating the “communication bottleneck” of single-core designs. The 4GB ECC RAM corrects memory errors (common in high-EMI environments), and 16GB flash stores firmware and application code with wear-leveling for 10+ year longevity.

Redundancy is its crown jewel. The primary CPU sends 1000 sync packets per second to the standby via a dedicated 1Gbps link, including real-time process values and logic states. If the primary detects a fault (CPU error, power loss, I/O communication failure), the standby activates in <5ms—faster than the response time of most industrial actuators. Unlike legacy controllers, it uses “stateful failover”: the standby doesn’t just take over, it resumes exactly where the primary left off, avoiding process transients.

Its IEC 61850 stack supports GOOSE messages with 1ms transmission latency—critical for tripping turbine breakers or isolating faulted equipment. The 2.5kV AC isolation between CPU and I/O protects sensitive electronics from high-voltage transients (common in power plants), while the -10°C to +65°C operating range handles unconditioned control rooms in desert or arctic locations. This isn’t just a controller—it’s a promise that critical processes stay online, even when components fail. For plants where downtime costs $10k+ per minute, that’s not a luxury—it’s a necessity.

Redundancy is its defining feature. Two PM864s operate in hot standby: the primary CPU sends real-time status updates to the standby via a dedicated sync link (100Mbps). If the primary detects a fault (e.g., power loss, processor error), the standby takes over in <10ms—faster than most process dynamics, so the loop never deviates. The CPU communicates with I/O modules via a 1Gbps backplane, ensuring fast data exchange with sensors and actuators.

Ruggedization is built in: conformal-coated PCBs resist oil and dust (critical for refineries), and the -20°C to +60°C operating range handles unconditioned control rooms in arctic or desert locations. Its IEC 61850 stack supports GOOSE messages for real-time control (e.g., tripping a breaker in 1ms) and MMS for data logging—integrating seamlessly with smart grid and Industry 4.0 systems. This isn’t a “one-size-fits-all” CPU; it’s engineered for the moments when every millisecond and every redundant component counts.