Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | 3BHE014023R0101 UFC789AE101 |

| Manufacturer | ABB |

| Product Category | Control Module (AC 800M Series) |

| Input Voltage | 24V DC (±15%) |

| Power Consumption | 10W (typical) |

| Processor | 32-bit RISC (500 MHz) |

| Memory | 256MB Flash, 128MB RAM |

| Communication Ports | 2× Ethernet, 1× RS-485, 1× USB 2.0 |

| Protocols Supported | IEC 61850, Modbus, PROFIBUS, OPC UA |

| Operating Temperature | -25°C to +70°C |

| Protection Class | IP20 |

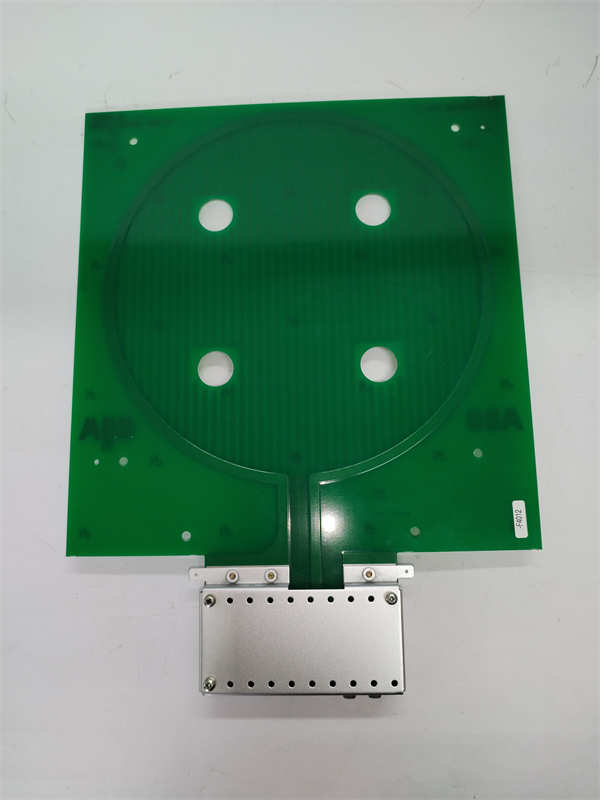

| Dimensions (W×H×D) | 120 × 100 × 75 mm |

| Weight | 550g |

| Compliance Standards | IEC 61131, UL 508, CE, RoHS |

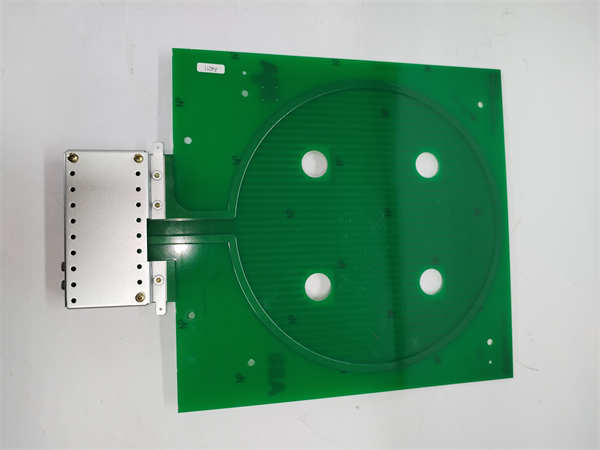

ABB 3BHE014023R0101 UFC789AE101

Product Introduction

The ABB 3BHE014023R0101 UFC789AE101 is a high-performance control module designed for ABB’s AC 800M programmable automation controller (PAC) series. This module serves as a central processing unit (CPU) for industrial automation, offering real-time control, data processing, and communication capabilities in demanding environments.Engineered for process automation, power generation, and manufacturing, the UFC789AE101 provides deterministic control execution and seamless integration with ABB’s System 800xA and third-party SCADA systems. Its dual Ethernet ports support IEC 61850 for substation automation, while Modbus and PROFIBUS ensure compatibility with legacy equipment.

Core Advantages and Technical Highlights

High-Speed Processing & Scalability:

500 MHz 32-bit RISC processor for real-time control

256MB Flash / 128MB RAM for complex logic execution

Supports up to 4 expansion modules (I/O, communication)

Industrial Communication & Cybersecurity:

IEC 61850 Ed.2 for digital substation integration

PROFIBUS DP-V1 for factory automation

OPC UA for secure data exchange

Role-based access control (RBAC) for cybersecurity

Robust Design for Harsh Environments:

Wide temperature range (-25°C to +70°C)

Conformal coated PCB (humidity/dust protection)

Vibration-resistant (5g) and surge-protected

User-Friendly Configuration:

ABB Automation Builder for programming

USB port for local firmware updates

LED diagnostics for quick troubleshooting

Typical Application Scenarios

The UFC789AE101 is used in:Power Generation & Distribution:Turbine control systems

Grid synchronization & load management

Oil & Gas:

Compressor control in pipelines

Safety shutdown systems (SIS)

Manufacturing:

Automated production line control

Robotic cell coordination

Water Treatment:

Pump station automation

Chemical dosing control

ABB 3BHE014023R0101 UFC789AE101

Related Model Recommendations

| Model | Description |

| UFC789BE101 | Enhanced version with PROFINET support |

| UFC760AE101 | Compact variant for less complex systems |

| CI854 | Communication interface (redundant Ethernet) |

| AC 800M PM891 | Redundant CPU module |

Installation, Commissioning & Maintenance

Installation Preparation:

Verify 24V DC power supply (±15%) stability.

Mount on DIN rail with 50mm clearance for cooling.

Use shielded cables for communication ports.

Maintenance Recommendations:

Monitor CPU temperature via diagnostics.

Backup configurations before firmware updates.

Replace every 10 years (recommended lifecycle).

Service & Guarantee Commitment

ABB provides:

60-month warranty

24/7 technical support

Firmware updates & security patches

On-site commissioning services

The UFC789AE101 undergoes:

1000-hour burn-in testing

EMC immunity validation

Mechanical stress testing