Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

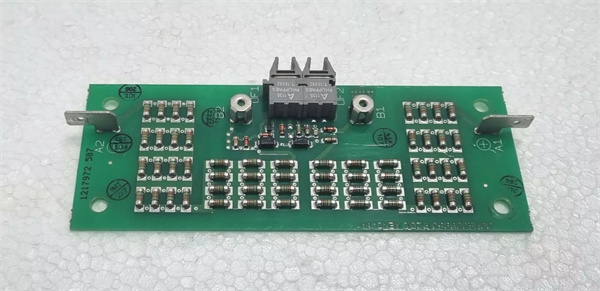

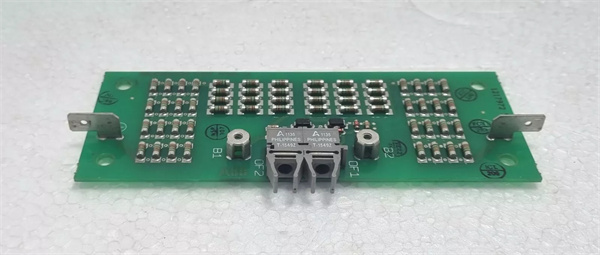

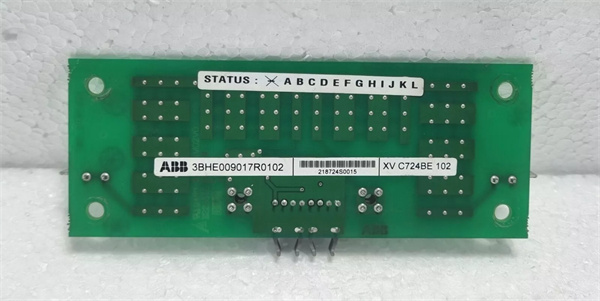

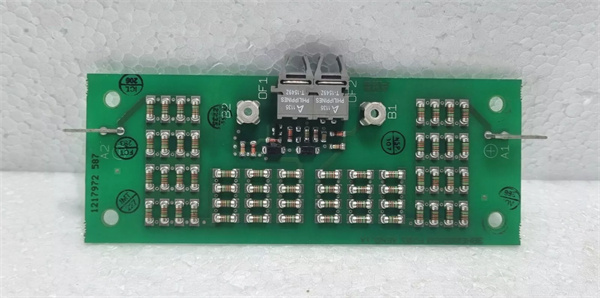

| Product Model | ABB 3BHE009017R0102 |

| Manufacturer | ABB |

| Product Category | Industrial Control Module |

| Compatible System | AC 800M Controller Family |

| Processor Type | PowerPC-based |

| Memory Capacity | 512MB DDR3 |

| Communication Interfaces | Ethernet, PROFIBUS, Modbus |

| Operating Voltage | 24V DC (±10%) |

| Power Consumption | 15W typical |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Dimensions | 120mm × 90mm × 70mm |

| Weight | 450g |

| Protection Rating | IP20 (requires enclosure) |

3BHE009017R0102

Product Introduction

The ABB 3BHE009017R0102 is a high-performance control module designed for ABB’s AC 800M industrial automation system. This advanced module serves as a critical component in distributed control systems (DCS), providing robust processing power for complex automation tasks in demanding industrial environments.

As part of ABB’s flagship control platform, the 3BHE009017R0102 offers exceptional reliability and real-time performance for process control applications. Its powerful PowerPC processor and ample memory capacity enable execution of sophisticated control algorithms while maintaining deterministic response times.

The module’s comprehensive communication capabilities allow seamless integration with field devices, HMI systems, and enterprise networks. The ABB 3BHE009017R0102 is particularly valued in industries requiring high availability and precise control, such as power generation, oil & gas, and chemical processing.

Core Advantages and Technical Highlights

High-Performance Processing:

Equipped with a PowerPC processor and 512MB DDR3 memory, the module delivers the computational power needed for complex control strategies and large-scale applications.

Versatile Communication:

Multiple built-in interfaces including Ethernet, PROFIBUS, and Modbus support flexible system architectures and easy integration with diverse field devices.

Robust Industrial Design:

Engineered for 24/7 operation in harsh environments, the module features industrial-grade components with extended temperature tolerance and vibration resistance.

Advanced Diagnostics:

Comprehensive self-diagnostics and status monitoring capabilities facilitate predictive maintenance and quick troubleshooting, minimizing system downtime.

Scalable Architecture:

Modular design allows easy system expansion and customization to meet specific application requirements.

Energy Efficient:

Optimized power consumption (15W typical) reduces overall system energy requirements while maintaining high performance.

3BHE009017R0102

Typical Application Scenarios

The ABB 3BHE009017R0102 is extensively used in:

Power Generation:

Turbine control systems

Boiler control applications

Plant-wide distributed control

Oil & Gas:

Refinery process control

Pipeline monitoring systems

Offshore platform automation

Chemical Processing:

Batch process control

Reactor temperature management

Safety instrumented systems

Water Treatment:

SCADA system integration

Pump station control

Filtration process automation

Related Model Recommendations

ABB 3BHE009018R0102: Enhanced version with expanded memory

ABB 3BHE009019R0102: Communication-focused variant

ABB 3BHE009020R0102: Safety-rated version for SIL2 applications

ABB 3BHE009021R0102: High-availability redundant configuration

ABB 3BHE009022R0102: Compact version for space-constrained installations

ABB 3BHE009023R0102: Extended temperature range variant

ABB 3BHE009024R0102: Cybersecurity-enhanced edition

ABB 3BHE009025R0102: Legacy system migration module

Installation and Commissioning

Installation Preparation:

Ensure proper mounting in control cabinet with adequate ventilation. Verify power supply stability (24V DC ±10%) and proper grounding. Prepare ESD-safe work environment.

Commissioning Procedure:

Install module in designated slot

Connect communication cables with proper termination

Load configuration using Control Builder M

Verify communication with all connected devices

Test all control functions before operational use

Maintenance Best Practices:

Regularly monitor module temperature

Keep firmware updated to latest version

Periodically review error logs

Maintain proper backup of configuration

Clean air vents to prevent overheating

Service and Warranty Information

ABB provides a standard 36-month warranty for the 3BHE009017R0102, covering:

Defects in materials and workmanship

Performance below specified parameters

Premature failure under normal conditions

Extended service options include:

Priority replacement program

On-site technical support

Firmware update services

System integration assistance

Custom configuration services

All modules undergo rigorous testing before shipment, including:

Environmental stress testing

Communication protocol validation

Long-term reliability testing

Performance benchmarking