Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

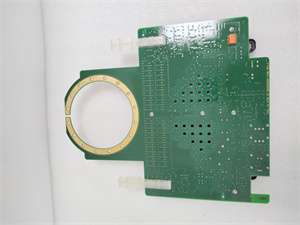

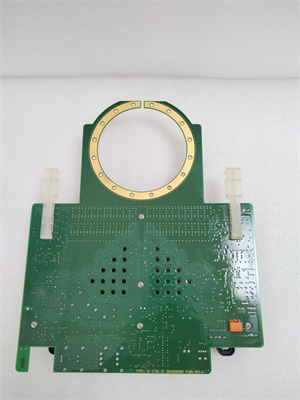

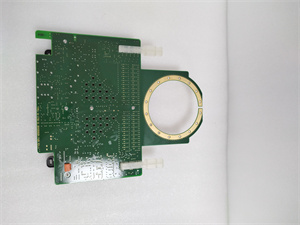

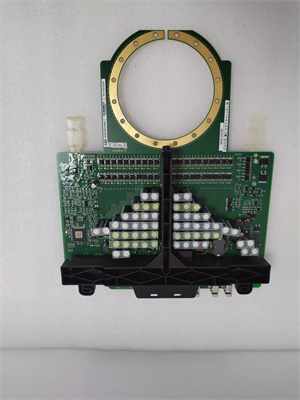

| Product Model | ABB 3BHB045647R0001 GVC736CE101 |

| Manufacturer | ABB |

| Product Category | Drive Control Module (ACS 800 Series) |

| Input Voltage | 24V DC (±10%) |

| Power Consumption | 20W typical |

| Operating Temperature | -25°C to +55°C |

| Communication Protocols | PROFIBUS DP, Modbus RTU, CANopen |

| Protection Rating | IP20 (IP54 with enclosure) |

| Processor | 32-bit RISC with DSP capabilities |

| Memory | 8MB Flash, 4MB RAM |

| Certifications | CE, UL, cUL, IEC 61800-5-1 |

ABB 3BHB045647R0001 GVC736CE101

Product Introduction

The ABB 3BHB045647R0001 GVC736CE101 is a high-performance drive control module designed for ABB’s ACS 800 industrial drive series. This advanced module serves as the central control unit for variable-speed drives, ensuring precise motor control in demanding industrial applications such as mining, metals, and heavy machinery.

Engineered for reliability, the GVC736CE101 integrates seamlessly with ABB’s DriveWare software, enabling advanced parameterization, diagnostics, and performance optimization. Its 32-bit RISC processor with DSP support ensures fast and accurate torque and speed control, making it ideal for dynamic applications requiring high precision.

Core Advantages and Technical Highlights

High-Performance Motor Control

32-bit RISC + DSP architecture for real-time control of AC motors.

Torque accuracy of ±0.5% for precise motion applications.

Supports vector control and DTC (Direct Torque Control) modes.

Robust Industrial Communication

PROFIBUS DP, Modbus RTU, and CANopen for PLC and SCADA integration.

ABB DriveCom protocol for fast data exchange with ABB systems.

Durability & Reliability

Wide operating temperature range (-25°C to +55°C).

Vibration-resistant (2g) and shock-proof (5g) for harsh environments.

IP20 standard (IP54 with optional enclosure).

Advanced Diagnostics & Safety

Built-in self-diagnostics for predictive maintenance.

Safe torque-off (STO) functionality (IEC 61800-5-1 compliant).

Fault logging with timestamp for troubleshooting.

Easy Integration & Configuration

ABB DriveWare software for quick setup and tuning.

Plug-and-play replacement for reduced downtime.

ABB 3BHB045647R0001 GVC736CE101

Typical Application Scenarios

Mining & Minerals Processing

Control of conveyor belts, crushers, and grinding mills with high torque demands.

Metals & Steel Industry

Rolling mill drives requiring precise speed synchronization.

Oil & Gas

Pump and compressor drives in offshore and onshore facilities.

Marine & Heavy Machinery

Winch and crane control with dynamic braking capabilities.

Water & Wastewater

Pump station optimization with energy-saving modes.

Related Model Recommendations

ABB 3BHB003154R0001 GVC732BE101 – Lower I/O variant for basic applications.

ABB 3BHB007209R0001 GVC750AE101 – High-end version with Ethernet/IP support.

ABB 3BHE021887R0101 NDAU-01C – Brake chopper module for ACS 800.

ABB 3BHE024855R0101 NINT-02C – Interface module for additional I/O.

ABB 3BHE039203R0101 NPPC-02C – Power supply module.

Installation, Commissioning & Maintenance

Installation Guidelines

Mount in a well-ventilated control cabinet (IP20) or sealed enclosure (IP54).

Use shielded cables for communication ports to prevent EMI.

Ensure proper grounding for noise immunity.

Commissioning

Configure via ABB DriveWare or DriveWindow software.

Perform motor ID run for optimal tuning.

Verify PROFIBUS/CANopen node addressing before startup.

Maintenance

Regular firmware updates via ABB support portal.

Monitor heat dissipation to prevent overheating.

Check error logs periodically for early fault detection.

Service & Warranty Commitment

24-month standard warranty with defect coverage.

Global 24/7 technical support (8-hour response for critical failures).

On-site commissioning & troubleshooting available.

10+ years of spare parts availability guaranteed.

Conclusion

The ABB 3BHB045647R0001 GVC736CE101 is a highly reliable, precise, and flexible drive control module for industrial automation. With its advanced motor control algorithms, robust communication, and rugged design, it ensures optimal performance in the most demanding drive applications.