Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | 3BHB002751R0106 |

| Manufacturer | ABB |

| Product Category | High-Performance Process Controller (CPU Module) |

| Processor | Dual-core Power Architecture, 1.5 GHz |

| Memory | 2 GB DDR3 RAM, 4 GB Flash Storage |

| Operating Voltage | 24 VDC (19.2–30 VDC) |

| Power Consumption | 18 W max |

| Operating Temperature | -25°C to +70°C |

| Communication Ports | 2x Ethernet (Gigabit), 2x Serial (RS-232/485), 1x USB 2.0, 1x SD Card Slot |

| Supported Protocols | OPC UA, Modbus TCP/RTU, IEC 61850, IEC 60870-5-104, PROFIBUS/Profinet (via extensions) |

| Redundancy | Hot-swappable, n+1 redundancy support |

| Physical Dimensions | 55 x 238 x 129 mm (WxHxD) |

| Mounting | DIN Rail (EN 60715) or vertical mounting |

| Certifications | UL 508, CE, ATEX Cat 3 Zone 2, IEC 61131-2, SIL 2 (application-dependent) |

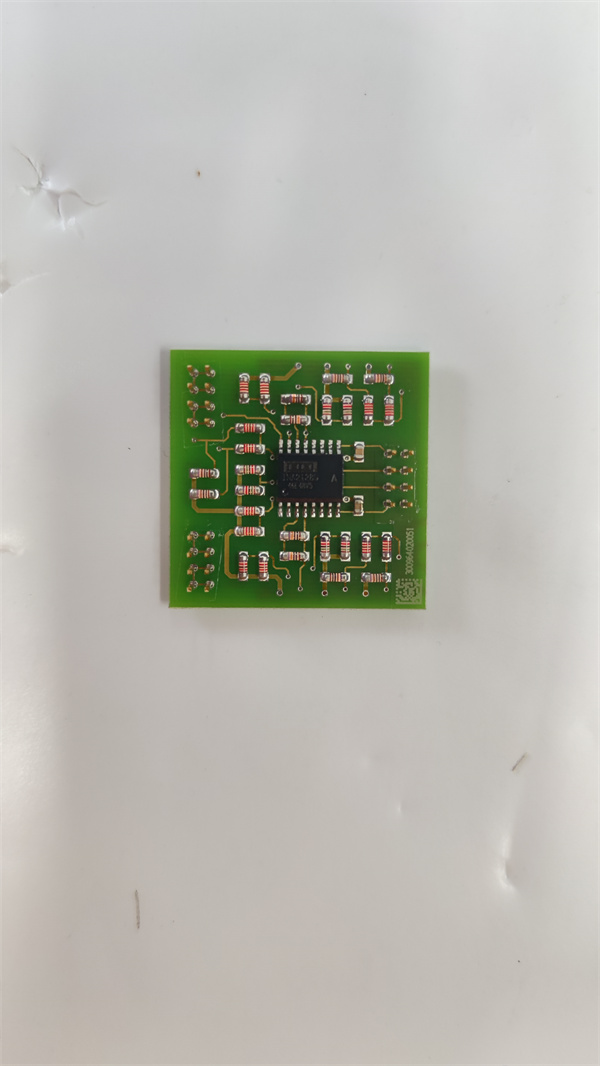

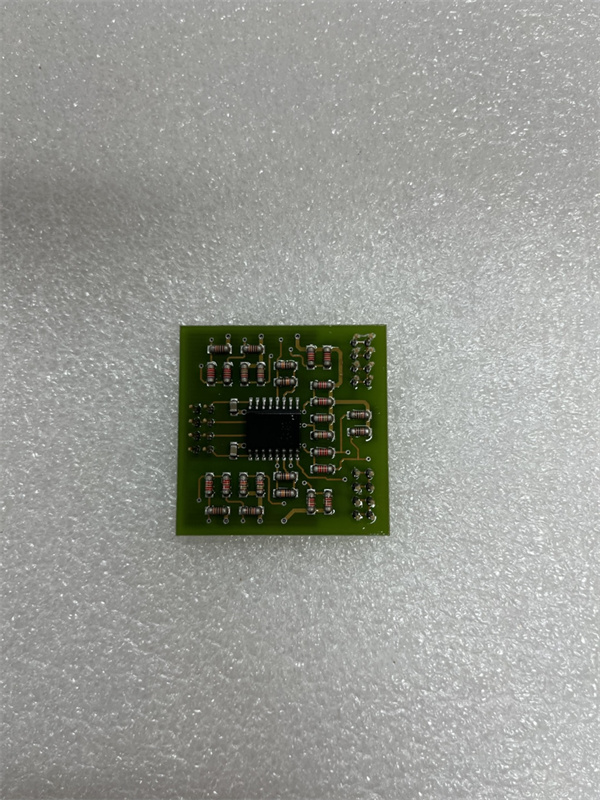

ABB 3BHB002751R0106

Product Introduction

The ABB 3BHB002751R0106 (PM865) is the pinnacle of ABB’s AC 800M series, engineered as a mission-critical process controller for large-scale industrial automation. This high-performance CPU module delivers deterministic control for complex applications in power generation, oil and gas, and chemical processing. Designed as the central intelligence of distributed control systems (DCS), the PM865 executes advanced regulatory control, sequencing, and safety logic with nanosecond precision.

As part of ABB’s Extended Automation 800xA ecosystem, the 3BHB002751R0106 integrates seamlessly with ABB’s I/O networks, safety controllers, and enterprise software. Its technical positioning targets high-availability environments requiring massive I/O handling (>10,000 tags) and computational intensity for model predictive control (MPC) or digital twin integration. The value of the ABB PM865 lies in its ability to unify process control, safety, and electrical systems into a single architecture, reducing engineering effort while maximizing plant uptime and operational intelligence.

Core Advantages and Technical Highlights

The ABB 3BHB002751R0106 excels through groundbreaking innovations:

Unmatched Performance: Dual 1.5 GHz cores with hardware-accelerated execution of IEC 61131-3 and C/C++ code handle complex algorithms at sub-millisecond cycles. Real-time deterministic performance ensures precision in critical processes like turbine control or reactor management.

Military-Grade Resilience: Featuring redundant hot-swappable power inputs and <0.1-second failover in redundant pairs, the PM865 achieves 99.999% availability. Conformal coating protects against humidity, dust, and corrosive atmospheres, while -25°C cold-start capability ensures reliability in Arctic operations.

Future-Ready Connectivity: Native OPC UA PUB/SUB over TSN (Time-Sensitive Networking) enables IIoT integration without gateways. Dual Gigabit Ethernet ports support parallel traffic segregation – one for real-time control, another for data historians or cloud analytics.

Cybersecurity Fortification: Hardware-trusted boot, role-based access control, and encrypted communication (AES-256) align with IEC 62443. Secure element chips prevent firmware tampering, critical for OT/IT convergence.

Engineering Efficiency:

Auto-discovery of ABB S800 I/O modules reduces commissioning time by 40%.

Online modification of control logic without process interruption.

Integrated SD card for one-click backup/restore of entire controller configurations.

Typical Application Scenarios

The ABB 3BHB002751R0106 dominates high-stakes industrial environments:

Power Generation:

Primary controller for combined-cycle gas turbines (CCGT), managing fuel-valve control, emissions optimization, and synchronization to grid frequency (≤2 ms response).

Nuclear plant safety-related systems (SIL 2 certified configurations), processing 5,000+ analog inputs for core monitoring.

Oil & Gas:

Offshore platform control: Manages subsea wellhead pressures, compressor anti-surge logic, and emergency shutdown (ESD) integration in Class I Div 2 zones.

Pipeline SCADA master station: Processes 15,000+ RTU data points for leak detection and batch tracking.

Chemical Processing:

Ethylene cracker advanced process control (APC): Executes real-time optimization models adjusting 200+ variables simultaneously.

Pharmaceutical batch reactors: Ensures FDA 21 CFR Part 11 compliance with electronic batch records and audit trails.

Water Management:

Large-scale desalination plants: Coordinates high-pressure pumps, membrane systems, and energy recovery devices with <0.01% control deviation.

ABB 3BHB002751R0106

Related Model Recommendations

PM864AK01: Previous-generation CPU; cost-effective solution for mid-range applications with 30% less processing power than the PM865.

CI871: PROFIBUS DP master interface module; extends 3BHB002751R0106 connectivity to legacy field devices.

SD835: Safety CPU for AC 800M; pairs with PM865 for integrated safety-instrumented systems (up to SIL 3).

TP854: Touch Panel HMI; provides local operator access to PM865 controller diagnostics.

S800 I/O Modules (e.g., AI825): High-density analog input cards; directly interfaced by the ABB PM865.

PM891K01: Compact controller for remote substations; complements PM865 in distributed architectures.

3BSE050818R1 (Combi I/O): Hybrid analog/digital module; reduces footprint for PM865-based cabinets.

Installation, Commissioning and Maintenance Instructions

Installation Preparation: Verify ambient temperature and humidity within specifications. Use ESD-safe tools and grounded wrist straps when handling the PM865. Ensure DIN rail (TH35-7.5) or mounting plate alignment. Pre-terminate power cables (18–22 AWG) with ferrule connectors. Isolate 24VDC supply with ≤5% ripple. Reserve 50mm clearance above/below for ventilation.

Maintenance Suggestions:

Quarterly: Clean air filters; verify firmware version against ABB security bulletins; check SD card health.

Annually: Calibrate controller internal clock via NTP; test redundancy switchover; inspect terminal tightness (0.6 Nm torque).

Use ABB’s Control Builder M software for predictive diagnostics: Monitor CPU load (<70% recommended), RAM usage, and heat sink temperature (via embedded sensors). Replace electrolytic capacitors after 8 years of continuous operation. Always maintain a synchronized spare 3BHB002751R0106 controller for critical processes.

Service and Guarantee Commitment

ABB guarantees the 3BHB002751R0106 for 36 months against manufacturing defects, with optional extended warranties up to 20 years for long-cycle plants. Global technical support includes:

24/7 emergency hotline with guaranteed 2-hour response for critical fault codes.

On-site commissioning and optimization services by ABB Certified Engineers.

Lifecycle management commitment: Guaranteed spare availability until 2045.

Complimentary access to ABB Ability™ Asset Vista for predictive maintenance insights.

Firmware updates with backward compatibility assurance for installed base since 2015.

Plant operators receive priority escalation paths and dedicated application support for ABB PM865 controllers integrated into 800xA systems.