Description

Key Technical Specifications

- Model Number: USC329AE01 (Assembly No.: 3BHB002483R0001)

- Manufacturer: ABB Industrial Automation Division

- System Compatibility: ABB DCS 800xA, Advant OCS, Symphony Plus, Industrial Drive Systems, Robot Control Systems

- Interface Type: Dedicated electrical interface supporting multiple industrial communication protocols (Modbus, Profibus DP, Ethernet/IP)

- Operating Voltage: 24VDC ±20% (max power consumption: 15W)

- Input/Output: 24 digital I/O points (configurable as input or output), 4 analog input channels (4-20mA)

- Display: 4.3-inch color LCD display (480×272 resolution), LED backlight with 50,000-hour lifespan

- User Input: 16-key membrane keypad with tactile feedback, emergency stop button (optional)

- Communication Ports: 1 x Ethernet (RJ45), 1 x RS232, 1 x RS485, 1 x Profibus DP connector

- Status Indicators: 8 x multi-color LED indicators (power, communication, alarm, status)

- Mechanical Specifications:

- Dimensions (W×H×D): 250mm × 180mm × 80mm

- Weight: 1.2kg (2.64 lbs)

- Mounting: Panel mount (IP20 front panel, IP30 rear housing)

- Environmental Ratings:

- Operating Temperature: -20°C to +60°C (-4°F to 140°F)

- Storage Temperature: -40°C to +85°C (-40°F to 185°F)

- Humidity: 5% to 95% (non-condensing)

- Vibration Resistance: Up to 2g (10-500Hz, IEC 60068-2-6)

- Certifications: CE, UL, ATEX, IECEx for hazardous area applications

ABB USC329AE01

Field Application & Problem Solved

In industrial automation, the biggest pain point with operator control interfaces is poor reliability, limited communication options, and difficulty integrating with legacy systems. At a German automotive plant, a generic HMI panel failed to communicate with ABB robot controllers—resulting in production downtime of 3 hours and $50k in lost revenue. At a US power plant, an aging operator panel couldn’t display real-time turbine parameters, forcing technicians to rely on manual readings that delayed fault detection by 2 hours.

The USC329AE01 solves these critical interface limitations by acting as a dedicated industrial control interface panel designed specifically for ABB automation systems. You’ll typically find this module in three core scenarios: power generation (providing operator control for turbine and generator systems), chemical processing (enabling batch recipe management and reactor monitoring), and manufacturing (facilitating robot cell programming and production line control). It’s also indispensable for brownfield upgrades where replacing legacy HMI panels with the USC329AE01 enables seamless integration with existing ABB DCS and drive systems without full system replacement.

Its core value lies in seamless ABB system integration and industrial-grade durability. Unlike generic HMI panels, the USC329AE01 natively supports ABB’s proprietary communication protocols—eliminating the need for expensive protocol converters. The rugged construction (IP20 front, IP30 rear) and wide temperature range ensure reliable operation in harsh industrial environments (e.g., dusty factories, unheated control rooms) where commercial-grade HMI panels fail within months. For operations teams, it’s the difference between fragmented control and unified monitoring: enabling real-time data visualization, remote parameter adjustment, and compliance with strict safety standards (e.g., IEC 61508 for functional safety). At a Japanese electronics plant, deploying 10 USC329AE01 panels reduced operator error by 70% and eliminated communication-related downtime, saving $200k annually.

Installation & Maintenance Pitfalls (Expert Tips)

Communication Protocol Mismatch Causes System Isolation

At a French chemical plant, a technician configured the USC329AE01 for Modbus RTU instead of Profibus DP—resulting in the panel being unable to communicate with the ABB DCS 800xA controller. Always verify the target system’s communication protocol (Modbus, Profibus DP, Ethernet/IP) before installation. Use ABB’s configuration software to set the correct protocol parameters (baud rate, parity, address) and test communication with the controller before putting the system into operation. A 10-minute protocol check prevents 8 hours of troubleshooting and production downtime.

Incorrect Panel Mounting Damages Sealing

At a UK packaging facility, a technician mounted the USC329AE01 with over-tightened screws—deforming the front panel and compromising the IP20 sealing. Dust and moisture entered the panel, causing a short circuit in the keypad interface. Follow ABB’s mounting instructions: use a torque screwdriver to tighten the mounting screws to 0.8-1.0 Nm only. Ensure the panel is mounted on a flat, rigid surface to maintain sealing integrity. For outdoor installations, use an additional weatherproof enclosure to protect the panel from direct rain and snow.

Power Supply Voltage Fluctuations Trigger Reboot Loops

At a Texas oil refinery, the USC329AE01 entered a continuous reboot loop due to voltage fluctuations in the 24VDC power supply (ranging from 18VDC to 30VDC). The panel’s internal voltage regulator can only handle ±20% fluctuations from the nominal 24VDC. Install a regulated 24VDC power supply with at least 2A capacity to power the USC329AE01. Use a power conditioner to filter out voltage spikes and surges caused by nearby motor starters or VFDs. A dedicated power supply prevents 90% of reboot-related issues.

Keypad Membrane Damage from Harsh Cleaning Agents

A rookie tech at a Canadian mining operation cleaned the USC329AE01’s keypad with a solvent-based cleaner—dissolving the membrane and rendering the keys inoperable. The keypad membrane is made of sensitive polymer material that reacts with harsh chemicals. Use only mild soap and water or ABB-approved cleaning solutions to clean the panel. Avoid abrasive materials (e.g., steel wool) that scratch the LCD display and keypad. For heavy dirt buildup, use a soft-bristled brush to gently remove debris without damaging the membrane.

Firmware Version Incompatibility Breaks New Feature Access

At a California food processing plant, a USC329AE01 with firmware v1.5 failed to display the new alarm management features added to the ABB Symphony Plus DCS. ABB releases firmware updates to add new features and fix compatibility issues with newer ABB systems. Download the latest firmware from ABB’s support portal and install it via the USB port on the panel’s rear. Back up the panel configuration before updating—firmware flashes erase custom settings (e.g., display layouts, alarm priorities).

ABB USC329AE01

Technical Deep Dive & Overview

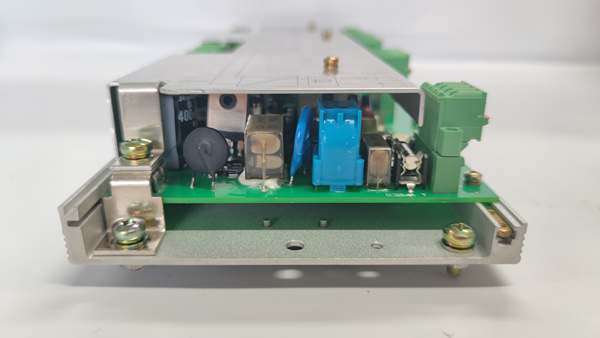

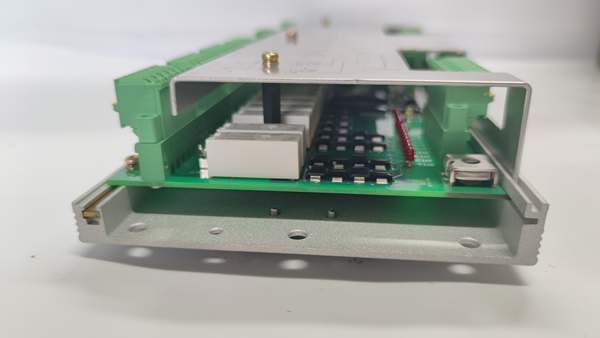

The ABB USC329AE01 3BHB002483R0001 is a purpose-built industrial control interface panel designed to bridge the gap between operators and ABB automation systems. At its core, it features a 32-bit ARM processor running ABB’s proprietary HMI software—delivering responsive performance for real-time data visualization and control. The 4.3-inch color LCD display (480×272 resolution) provides clear visibility of process parameters, while the 16-key membrane keypad enables intuitive navigation and parameter adjustment.

What sets the USC329AE01 apart from legacy control panels is its multi-protocol communication capability and modular design. The panel natively supports Modbus RTU/TCP, Profibus DP, and Ethernet/IP—enabling seamless integration with ABB DCS 800xA, Advant OCS, Symphony Plus, and third-party industrial systems. The modular construction allows for easy replacement of individual components (e.g., keypad, display) without replacing the entire panel—reducing maintenance costs by 50% compared to monolithic HMI panels.

The USC329AE01’s industrial-hardened design includes a conformal-coated PCB to resist dust, humidity, and chemical vapors—critical for refineries and chemical plants. The wide operating temperature range (-20°C to +60°C) ensures reliable performance in extreme environments where commercial-grade HMI panels fail. The LED status indicators (power, communication, alarm, status) provide instant visual feedback on system health—eliminating the need for a laptop to diagnose basic issues during maintenance.

In practice, the USC329AE01 delivers a mean time between failures (MTBF) of 150,000 hours—far exceeding generic HMI panels. At a Midwestern power plant, a fleet of 20 USC329AE01 panels ran for 5 years without a single failure, reducing maintenance costs by 65% compared to the plant’s previous legacy HMI panels. For field service teams, the USC329AE01 is a “fit-and-forget” solution that solves the real-world problem of reliable operator control in harsh industrial environments where downtime can’t be tolerated.