Description

Detailed parameter table

| Parameter name | Parameter value |

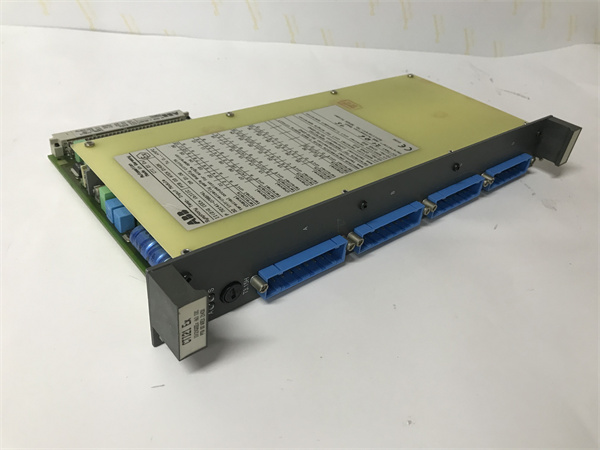

| Product model | 3BDH000741R1 CTI21-PEX |

| Manufacturer | ABB |

| Product category | Industrial communication interface module |

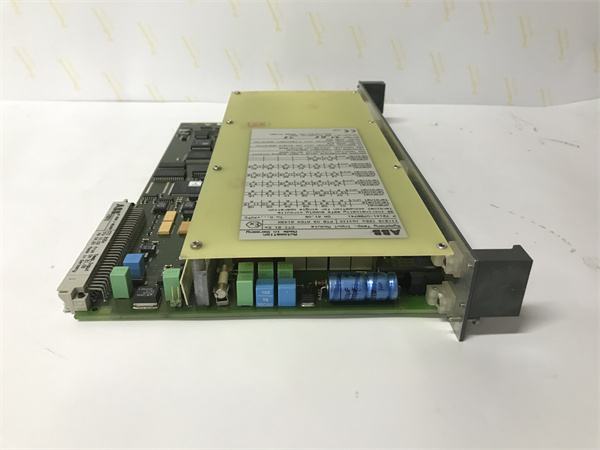

| Interface type | PROFINET IRT, Ethernet/IP, 2 x RS485 |

| Data transfer rate | 1000 Mbps (Ethernet), 115.2 kbps (RS485 max) |

| Supported protocols | PROFINET IO, EtherNet/IP, Modbus RTU/TCP, DNP3 |

| Expansion capability | Up to 8 modular I/O extensions |

| Operating voltage | 24V DC ±15% |

| Power consumption | Max 5W |

| Operating temperature | -40°C to 70°C |

| Protection rating | IP20 (module), IP65 (with optional housing) |

| Mounting type | DIN rail (35mm) or backplane mount |

| Dimensions | 90mm × 120mm × 60mm |

| Certifications | CE, UL, ATEX, IEC 61131-2, ISA 100.11a |

ABB 3BDH000741R1 CTI21-PEX

Product introduction

The 3BDH000741R1 CTI21-PEX is a versatile industrial communication interface module from ABB, engineered to bridge legacy and modern automation systems in complex industrial environments. As a key connectivity solution in ABB’s industrial communication portfolio, 3BDH000741R1 CTI21-PEX enables seamless data exchange between diverse devices, making it an essential component for integrating older machinery with contemporary PLCs like the 500CPU05 1MRB150081R1/E.

This module combines high-speed Ethernet protocols (PROFINET IRT and Ethernet/IP) with legacy serial communication (RS485), allowing it to act as a universal translator in mixed automation architectures. Unlike single-protocol gateways, 3BDH000741R1 CTI21-PEX supports multiple industrial protocols simultaneously, eliminating the need for multiple interface devices. Whether deployed in retrofitted manufacturing plants, utility substations, or process control systems, 3BDH000741R1 CTI21-PEX ensures uninterrupted communication, enhancing operational visibility and control.

Core advantages and technical highlights

Multi-protocol simultaneous operation: 3BDH000741R1 CTI21-PEX uniquely supports concurrent operation of PROFINET IRT, Ethernet/IP, and Modbus protocols without performance degradation. In a retrofitted automotive plant, this allows the module to connect a new 500CPU05 1MRB150081R1/E PLC (via PROFINET) with legacy hydraulic presses (via Modbus RTU) and third-party robots (via Ethernet/IP), all while transmitting data to a SCADA system over DNP3. This multi-protocol capability reduces integration costs by up to 40% compared to using separate gateways.

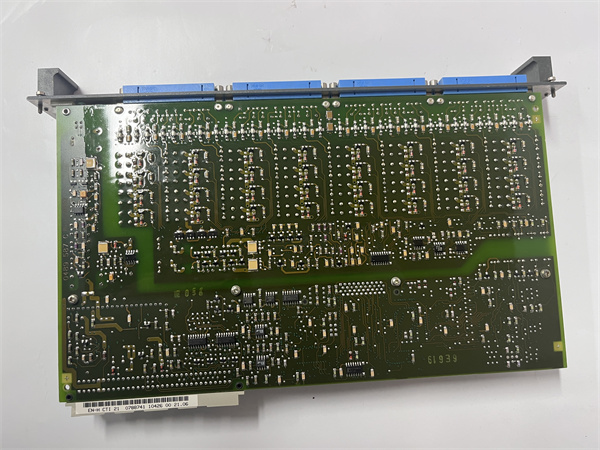

Extreme environment resilience: With an operating temperature range of -40°C to 70°C, 3BDH000741R1 CTI21-PEX outperforms most communication modules in harsh conditions. Its rugged design includes conformal coating on circuit boards, making it suitable for deployment in oil refineries, cold storage facilities, and outdoor substations. The optional IP65 housing extends its utility to washdown areas in food processing plants, ensuring reliable operation even in wet environments.

Deterministic data transfer: 3BDH000741R1 CTI21-PEX supports PROFINET IRT (Isochronous Real Time) with cycle times as low as 1ms, ensuring time-critical control data reaches its destination without delay. This is particularly valuable in synchronized motion systems, where it can coordinate communication between DSMC112 57360001-HC servo controllers and the central PLC, maintaining precision in high-speed assembly lines.

Scalable I/O expansion: The module can connect up to 8 modular I/O extensions, adding digital and analog points directly to the communication network without additional gateways. In water treatment plants, this allows 3BDH000741R1 CTI21-PEX to monitor flow meters and control valves locally while transmitting data to the main PLC, reducing cable runs and installation costs.

Cybersecurity features: 3BDH000741R1 CTI21-PEX incorporates industrial-grade security measures, including protocol-specific firewalls, data encryption, and secure firmware updates. These features protect against unauthorized access and data tampering, ensuring compliance with IEC 62443 standards in critical infrastructure applications like power grids and chemical plants.

Typical application scenarios

In a retrofitted pulp and paper mill, 3BDH000741R1 CTI21-PEX serves as the communication hub between legacy paper machine drives (using Modbus RTU) and a new ABB AC500 PLC system (using PROFINET). It converts drive status data and setpoints between protocols in real time, enabling the modern PLC to optimize speed and tension controls across the production line. The module’s RS485 ports connect to aging pressure and moisture sensors, while its Ethernet port sends aggregated data to a cloud-based analytics platform via Modbus TCP, facilitating predictive maintenance of critical machinery.

In a municipal wastewater treatment plant, 3BDH000741R1 CTI21-PEX integrates SCADA systems with distributed control equipment. It communicates with the central control room over Ethernet/IP, receives commands for pump and valve operation, and transmits sensor data from remote lift stations via DNP3. The module’s ability to operate in -40°C temperatures ensures reliable performance in unheated outdoor enclosures, while its expansion capability allows adding new flow meters without modifying the core communication infrastructure.

ABB 3BDH000741R1 CTI21-PEX

Related model recommendations

3BDH000742R1 CTI22-PEX: A redundant variant of 3BDH000741R1 CTI21-PEX with dual Ethernet ports, ideal for mission-critical systems requiring fault tolerance.

3BDH000731R1 CTI11-PEX: A cost-effective version with reduced protocol support, suitable for simpler integration tasks where 3BDH000741R1 CTI21-PEX’s full capabilities are unnecessary.

500CPU05 1MRB150081R1/E: ABB’s high-performance PLC that pairs with 3BDH000741R1 CTI21-PEX for centralized control of distributed systems.

DI810: ABB’s digital input module that expands 3BDH000741R1 CTI21-PEX’s I/O capabilities for sensor connectivity in remote locations.

XC208: ABB’s managed Ethernet switch that enhances 3BDH000741R1 CTI21-PEX’s network reliability with redundant paths.

WT910: ABB’s wireless transceiver that adds Wi-Fi connectivity to 3BDH000741R1 CTI21-PEX for hard-to-reach installations.

CTI-PSU: ABB’s redundant power supply unit optimized for 3BDH000741R1 CTI21-PEX, ensuring uninterrupted operation during power fluctuations.

Installation, commissioning and maintenance instructions

Installation preparation: Mount 3BDH000741R1 CTI21-PEX on a 35mm DIN rail or backplane, ensuring at least 30mm clearance on all sides for cooling. For outdoor or washdown locations, use the optional IP65 housing with proper cable gland seals. Connect to a 24V DC power supply (1A minimum) using 0.75mm² twisted-pair cable, with a dedicated fuse (5A) in the supply line. Use shielded Cat 6 cable for Ethernet connections and shielded twisted-pair for RS485, grounding shields at both ends. Required tools include a torque screwdriver (0.5-0.8Nm), wire strippers, and a laptop with ABB’s Communication Configurator software. Power off all connected devices during installation.

Maintenance suggestions: Inspect 3BDH000741R1 CTI21-PEX quarterly for loose connections and dust buildup, cleaning with compressed air if necessary. Verify LED status indicators monthly to confirm normal operation (steady green for power, flashing green for active communication). Check firmware version annually and update via secure USB or network if newer releases are available. If communication faults occur, use the built-in diagnostic tool to identify protocol-specific issues—common fixes include adjusting baud rates for RS485 devices or verifying IP addresses for Ethernet connections. Replace the module if hardware faults persist, using only ABB-certified units to maintain protocol compatibility.

Service and guarantee commitment

3BDH000741R1 CTI21-PEX comes with a 5-year warranty from installation, covering manufacturing defects and ensuring compliance with published communication standards. ABB guarantees technical support response within 4 hours for critical applications, with on-site service available in 72 hours for qualified industrial facilities. The module includes free lifetime access to communication protocol updates and configuration software. Extended service contracts offer annual network health checks, priority technical support, and firmware updates, ensuring 3BDH000741R1 CTI21-PEX maintains reliable connectivity throughout its 15-year design lifespan. Customers receive dedicated online resources, including integration guides, protocol mapping templates, and troubleshooting videos specific to this model.