Description

Detailed parameter table

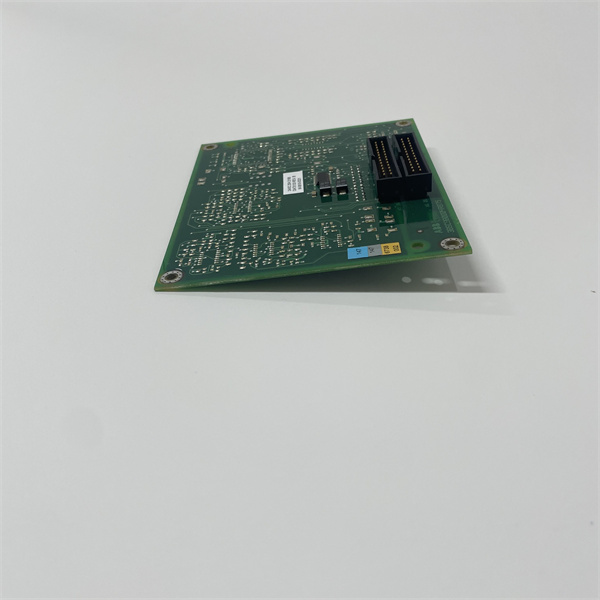

| Parameter name | Parameter value |

| Product model | 3ASC25H219B DATX133 |

| Manufacturer | ABB |

| Product category | Drive auxiliary terminal board |

| Compatible drives | ABB ACS800, ACS880 series frequency converters |

| Input signals | 8 digital inputs (24 V DC), 4 analog inputs (0-10 V/4-20 mA) |

| Output signals | 6 digital outputs (relay), 2 analog outputs (4-20 mA) |

| Power supply | 24 V DC ±10% (from drive or external source) |

| Isolation | 2.5 kV AC (signal to drive, signal to ground) |

| Dimensions | 180 mm × 120 mm × 40 mm |

| Mounting type | DIN rail mount (35 mm) or panel mount |

| Protection rating | IP20 |

| Operating temperature | -10°C to 60°C |

| Certifications | IEC 61010-1, CE, UL |

ABB 3ASC25H219B DATX133

Product introduction

The 3ASC25H219B DATX133 is a high-performance drive auxiliary terminal board from ABB, specifically designed to extend the I/O capabilities of ABB’s ACS800 and ACS880 frequency converters. As a key component in ABB’s drive accessory portfolio, 3ASC25H219B DATX133 serves as a centralized interface for connecting external sensors, actuators, and control devices to the drive, simplifying wiring and enhancing system flexibility.

Engineered for industrial environments, 3ASC25H219B DATX133 provides reliable signal conversion and isolation, ensuring accurate communication between the drive and field devices. Its compact design and versatile mounting options make it easy to integrate into control cabinets, while compatibility with standard industrial signals (0-10 V, 4-20 mA, 24 V DC) allows seamless connection to PLCs, HMIs, and other automation components. Whether used in motor control systems for pumps, fans, or conveyors, 3ASC25H219B DATX133 enhances the functionality of ABB drives, enabling precise control and monitoring in diverse industrial applications.

Core advantages and technical highlights

Seamless drive integration: 3ASC25H219B DATX133 is specifically engineered for ABB ACS800 and ACS880 drives, ensuring plug-and-play compatibility without the need for complex configuration. The terminal board communicates with the drive via a dedicated interface, enabling real-time data exchange and synchronized operation. In a water treatment plant, this integration allows the drive controlling a centrifugal pump to receive flow rate signals (via the board’s analog inputs) and adjust speed accordingly, maintaining consistent pressure without additional programming.

Enhanced I/O expansion: With 8 digital inputs, 4 analog inputs, 6 relay outputs, and 2 analog outputs, 3ASC25H219B DATX133 significantly expands the drive’s native I/O capacity. This eliminates the need for external I/O modules, reducing cabinet space and wiring complexity. In a manufacturing facility, for example, the board can connect limit switches (digital inputs), a pressure transmitter (analog input), motor overload alarms (relay outputs), and a speed reference signal (analog output) to the drive—all in a single compact unit.

Robust signal isolation: 3ASC25H219B DATX133 features 2.5 kV AC isolation between signals, the drive, and ground, protecting sensitive drive electronics from electrical noise, ground loops, and voltage transients. This isolation is critical in environments with high-power equipment, such as steel mills or plastic extrusion plants, where electromagnetic interference can disrupt signal integrity. It ensures that a noisy motor start doesn’t corrupt the speed reference signal, preventing unexpected drive behavior.

Flexible power options: The terminal board can be powered either by the drive’s internal 24 V DC supply or an external source (e.g., AFP9075355 3BHS537443 power supply), providing redundancy in critical applications. In a food processing line, this flexibility allows the board to remain operational even if the drive’s internal power fails, ensuring emergency stop signals (via digital inputs) still trigger the drive to shut down, maintaining operator safety.

Typical application scenarios

In a HVAC system for a large commercial building, 3ASC25H219B DATX133 is integrated with an ABB ACS880 drive controlling a variable-speed fan. The board’s analog inputs receive temperature and pressure sensor data from the ductwork, while digital inputs monitor fire alarm contacts and fan filter status. Relay outputs activate damper actuators and alarm lights, and an analog output sends the actual fan speed to a building management system. The isolation provided by 3ASC25H219B DATX133 prevents noise from the building’s electrical system from interfering with the drive’s speed control loop, ensuring stable airflow and energy efficiency.

In a material handling conveyor system, 3ASC25H219B DATX133 connects an ACS800 drive to a PLC and field devices. Digital inputs detect conveyor belt position via photoelectric sensors, analog inputs monitor motor bearing temperature, and relay outputs control belt brakes and divertor valves. The board’s external power supply (AFP9075355 3BHS537443) ensures that critical safety signals—like a “belt jam” input—remain active during drive faults, allowing the PLC to trigger an emergency stop. This integration simplifies troubleshooting, as all signals are routed through the board, making it easy to isolate wiring issues.

Related model recommendations

ABB ACS880-01-04A1-3: A frequency converter that works with 3ASC25H219B DATX133 for precise motor control in industrial applications.

ABB AFP9075355 3BHS537443: A power supply unit that provides external 24 V DC power to 3ASC25H219B DATX133 for redundancy.

ABB NBIO-31 3BSE011337R1: A digital I/O module that complements 3ASC25H219B DATX133 in larger automation systems requiring additional discrete signals.

ABB CI627A 3BSE017457R1: A communication module that enables data exchange between the drive (via 3ASC25H219B DATX133) and PROFIBUS networks.

ABB TB857: A surge protection terminal block that safeguards 3ASC25H219B DATX133’s input signals from voltage spikes.

ABB 200900-004: A terminal block used to terminate field wiring for 3ASC25H219B DATX133’s I/O channels.

Installation, commissioning and maintenance instructions

Installation preparation: Mount 3ASC25H219B DATX133 on a 35 mm DIN rail or panel using the provided hardware, ensuring 50 mm clearance for wiring. Connect the board to the ABB drive via the dedicated interface cable (part number 3XK1010-1AA00). Wire field devices to the terminal blocks: use 0.5-1 mm² shielded cable for analog signals and 0.75-1.5 mm² cable for digital signals. Ground cable shields at the board end. Power the board via the drive’s internal 24 V supply or an external source like AFP9075355 3BHS537443, ensuring correct polarity. Use a torque screwdriver set to 0.5 Nm for terminal connections. Power off the drive and external power during installation.

Maintenance suggestions: Inspect 3ASC25H219B DATX133 quarterly for loose connections, dust accumulation, and corrosion on terminals. Clean the board with a dry cloth or compressed air—avoid liquids. Test input/output functionality semi-annually by sending test signals from a signal generator and verifying drive response or output activation. Check isolation resistance annually using a megohmmeter (2.5 kV for 1 minute) to ensure it remains above 100 MΩ. If signals are intermittent or the board fails communication with the drive, check wiring and replace the interface cable if damaged. Use only ABB-certified replacement boards to maintain compatibility and safety.

Service and guarantee commitment

3ASC25H219B DATX133 is backed by a 3-year warranty from the date of installation, covering manufacturing defects and ensuring compatibility with ABB ACS800/ACS880 drives. ABB’s technical support team provides response within 4 hours for critical issues, with guidance on wiring, configuration, and troubleshooting available 24/7.

The warranty includes access to installation guides, wiring diagrams, and compatibility matrices. Extended service contracts offer annual inspection and testing, ensuring the terminal board maintains reliable performance throughout its 10-year design lifespan. ABB’s commitment to quality underscores confidence in 3ASC25H219B DATX133 as a durable and integral component in drive-based automation systems.