Description

Detailed parameter table

| Parameter name | Parameter value |

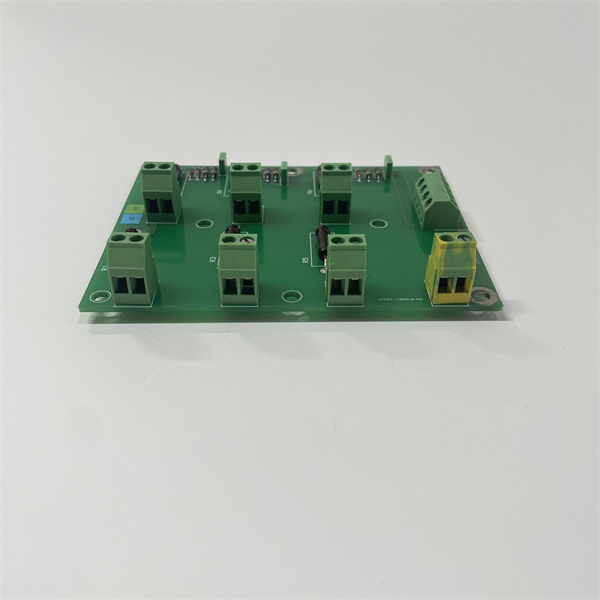

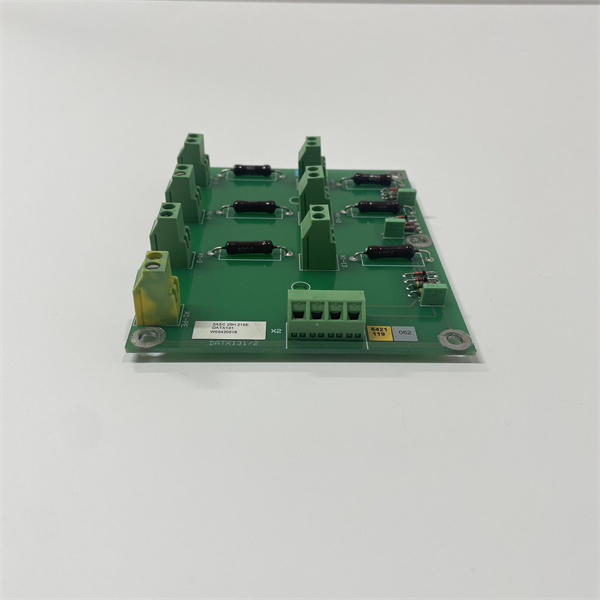

| Product model | 3ASC25H215E DATX131 |

| Manufacturer | ABB |

| Product category | Industrial communication interface module (for robot controller systems) |

| Communication protocols | PROFINET, Ethernet/IP, Modbus TCP/IP |

| Data transfer rate | Up to 1000 Mbps (Gigabit Ethernet) |

| Interface type | 2 x RJ45 Ethernet ports, 1 x DB9 serial port (RS232) |

| Operating voltage | 24 V DC ±10% |

| Power consumption | Max 8 W |

| Operating temperature | 0°C to 60°C |

| Storage temperature | -25°C to 70°C |

| Protection rating | IP20 |

| Dimensions | 150mm × 100mm × 40mm |

| Weight | 0.35 kg |

| Certifications | IEC 61131-2, CE, UL, RoHS |

| Compatibility | ABB IRC5 and OmniCore robot controllers |

| Mounting type | DIN rail (35mm) or panel mounting |

| Isolation rating | 2.5 kV AC (Ethernet ports to power supply) |

| Diagnostic functions | LED status indicators, error logging |

ABB 3ASC25H215E DATX131

Product introduction

The ABB 3ASC25H215E DATX131 is a high-performance industrial communication interface module designed to serve as a critical connectivity hub for ABB robot controller systems, enabling seamless data exchange between robotic cells and factory-wide automation networks. As a key component in ABB’s robot communication ecosystem, this module bridges the gap between robot controllers (such as IRC5 and OmniCore) and external devices—including PLCs, HMIs, SCADA systems, and manufacturing execution systems (MES)—facilitating real-time coordination of robotic operations in complex industrial environments.

Equipped with multi-protocol support (PROFINET, Ethernet/IP, Modbus TCP/IP) and Gigabit Ethernet capabilities, the ABB 3ASC25H215E DATX131 ensures flexible integration into diverse automation architectures, whether legacy or modern. Its dual Ethernet ports enable redundant network configurations, enhancing reliability in mission-critical applications where communication downtime could disrupt production. The included RS232 serial port provides compatibility with older devices, ensuring smooth transitions during factory upgrades.

Built to withstand the rigors of industrial settings, the module operates reliably in temperatures ranging from 0°C to 60°C, resisting electromagnetic interference (EMI) and vibration common in manufacturing facilities. Its compact design (150mm × 100mm × 40mm) allows for space-efficient installation in control cabinets, while its rugged construction ensures long-term durability. Whether deployed in automotive assembly lines, electronics manufacturing, or material handling systems, the ABB 3ASC25H215E DATX131 delivers consistent performance, enabling synchronized and efficient robotic operations.

Core advantages and technical highlights

Multi-protocol flexibility

The ABB 3ASC25H215E DATX131 supports PROFINET, Ethernet/IP, and Modbus TCP/IP—three of the most widely used industrial protocols—eliminating the need for protocol converters and simplifying integration into mixed-vendor automation systems. For example, in an automotive plant, it can communicate with a Siemens PLC via PROFINET while sending production data to a Rockwell Automation SCADA system via Ethernet/IP, ensuring seamless coordination between robots and upstream/downstream equipment.

High-speed, redundant communication

With Gigabit Ethernet capability (up to 1000 Mbps), the module enables fast transfer of large datasets—such as 3D vision system outputs or robot motion plans—without latency. Its dual Ethernet ports support redundant network topologies (e.g., ring or star configurations), where a primary and backup network path ensure communication continues uninterrupted if one link fails. This redundancy is critical in high-throughput applications like packaging lines, where even a brief communication outage can cause production bottlenecks.

Seamless robot controller integration

Designed specifically for ABB’s IRC5 and OmniCore robot controllers, the ABB 3ASC25H215E DATX131 offers plug-and-play compatibility, reducing commissioning time. It integrates with ABB’s RobotStudio software, allowing engineers to configure communication settings, monitor network traffic, and troubleshoot issues from a single interface. This tight integration ensures optimal performance, as the module is pre-optimized to handle robot-specific data formats (e.g., joint positions, error codes).

Robust industrial design

Engineered to operate in 0°C to 60°C environments, the module thrives in the temperature fluctuations common in factory settings—from cool electronics cleanrooms to warm foundries. Its 2.5 kV AC isolation between Ethernet ports and the power supply protects sensitive robot controller electronics from voltage transients, while EMI shielding prevents interference from nearby motors, welders, or variable frequency drives. This ruggedness ensures stable communication in electrically noisy environments.

Comprehensive diagnostics

The module features LED status indicators for power, Ethernet link, and data activity, providing at-a-glance visibility into operational health. It also logs error codes (e.g., network timeouts, protocol mismatches) that can be accessed via RobotStudio or HMI, enabling rapid troubleshooting. For example, a blinking Ethernet LED can alert maintenance teams to a loose cable, while error logs can identify intermittent protocol errors caused by network congestion.

Typical application scenarios

Automotive body assembly

In a car body welding line, the ABB 3ASC25H215E DATX131 connects multiple ABB robots to a central PLC and a vision system. It receives part position data from the vision system via Ethernet/IP, sends robot motion commands from the PLC via PROFINET, and transmits weld quality data to an MES system via Modbus TCP/IP. The dual Ethernet ports ensure communication continues even if one network link is disrupted by welding arcs, maintaining production continuity.

Electronics manufacturing

In a printed circuit board (PCB) assembly facility, the module links ABB pick-and-place robots to a machine vision system and a conveyor control PLC. It transfers high-resolution PCB images from the vision system (via Gigabit Ethernet) to the robot controller, enabling precise component placement. Simultaneously, it sends conveyor speed commands via PROFINET, ensuring robots and conveyors are synchronized to within milliseconds—critical for preventing component damage.

Food and beverage packaging

In a beverage bottling plant, the ABB 3ASC25H215E DATX131 connects palletizing robots to a line controller and a barcode scanner. It receives bottle count data from the scanner via Modbus TCP/IP, allowing the robot to adjust pallet patterns dynamically. It also sends robot status (e.g., “pallet full”) to the line controller via Ethernet/IP, triggering conveyor diverts to route empty pallets to the robot. Redundant Ethernet ensures the robot doesn’t stop if a network cable is accidentally disconnected.

Warehouse automation

In a distribution center, the module integrates ABB mobile robots (AGVs) with a warehouse management system (WMS). It receives pick orders from the WMS via PROFINET and sends AGV location data back, enabling real-time tracking. The RS232 port connects to a barcode reader on the AGV, allowing manual input of order numbers if the wireless network is temporarily unavailable. This hybrid connectivity ensures the AGVs remain operational in all scenarios.

ABB 3ASC25H215E DATX131

Related model recommendations

ABB 3ASC25H216E DATX132: A variant with 4 Ethernet ports for larger-scale networks requiring more connections.

ABB IRC5 Controller: The robot controller that pairs with the ABB 3ASC25H215E DATX131 for advanced motion control and programming.

ABB CI854A 3BSE022469R1: A PROFINET repeater that extends the communication range of the ABB 3ASC25H215E DATX131 in large factories.

ABB 800xA Robot Integration Module: Integrates robot data from the ABB 3ASC25H215E DATX131 into the 800xA DCS, enabling plant-wide monitoring.

ABB TB857 3BSE013269R1: A surge-protected terminal block that enhances the module’s noise immunity in high-EMI environments (e.g., near welding robots).

ABB OCAHG 492838402: A fiber optic transceiver that, when paired with the ABB 3ASC25H215E DATX131, extends communication over long distances (up to 10 km) in large facilities.

Installation, commissioning and maintenance instructions

Installation preparation

Verify compatibility with the robot controller (IRC5 or OmniCore) and ensure the host system has the latest firmware supporting the ABB 3ASC25H215E DATX131.

Mount the module on a 35mm DIN rail or via panel-mounting holes in the robot controller cabinet, ensuring 50mm clearance for ventilation. Avoid locations near heat sources (e.g., power supplies) or high-voltage cables.

Prepare tools: torque screwdriver (0.5-0.8 Nm), Ethernet cable tester, and ESD-safe wristband. Use shielded twisted-pair Ethernet cables (Cat 5e or higher) with metal connectors for EMI protection.

Check the power supply (24 V DC ±10%) and install a 1A fuse in the supply line to protect against overcurrent.

Installation steps

Power off the robot controller. Connect the 24 V DC power supply to the module’s power terminals, ensuring correct polarity (positive to +V, negative to 0V).

Connect Ethernet cables to the module’s RJ45 ports: one for primary network communication, the second for redundant backup (if used). Connect the RS232 port to legacy devices (e.g., barcode scanners) using a DB9 cable.

Secure all connections with cable ties to prevent strain on terminals. Ground the module’s shield connection to the cabinet ground for enhanced EMI protection.

Power on the robot controller and verify the module’s power LED illuminates green. Check Ethernet link LEDs (one per port) to confirm network connectivity.

Commissioning steps

Launch ABB RobotStudio and connect to the robot controller. Navigate to the communication settings and select the ABB 3ASC25H215E DATX131 from the list of connected devices.

Configure network parameters (IP address, subnet mask, gateway) and enable required protocols (e.g., PROFINET for PLC communication, Modbus TCP/IP for MES integration).

Test communication with each connected device:

Send a test signal from the PLC to the robot (e.g., “start cycle”) and confirm the robot responds.

Transmit robot status data (e.g., “cycle count”) to the MES and verify it is received correctly.

Validate redundancy by disconnecting the primary Ethernet cable and confirming communication switches to the backup port without interruption.

Run a full production cycle and monitor network performance using RobotStudio’s diagnostic tools, ensuring no packet loss or latency spikes.

Maintenance suggestions

Inspect the ABB 3ASC25H215E DATX131 quarterly for dust accumulation; clean with compressed air (low pressure) to prevent overheating. Check Ethernet and power connections for tightness, retorquing terminals to 0.6 Nm if loose.

Monitor network performance monthly via RobotStudio, tracking metrics like packet loss, latency, and protocol errors. Address issues (e.g., replace damaged cables) if errors exceed 0.1% of total traffic.

Update the module’s firmware annually (or as recommended by ABB) to ensure compatibility with new protocols and security patches. Use RobotStudio to perform firmware updates safely.

Test redundant network failover semi-annually by disconnecting the primary Ethernet port during non-production hours. Confirm the robot continues operating without interruption using the backup port.

Replace the module if it exhibits persistent communication faults (e.g., unresponsive ports, protocol failures) that cannot be resolved by reconfiguration or cable replacement. Store spare modules in anti-static packaging at -25°C to 70°C.

Service and guarantee commitment

The ABB 3ASC25H215E DATX131 comes with a 36-month warranty from the date of installation, covering manufacturing defects and ensuring compatibility with ABB robot controllers. ABB guarantees that any module failing to meet performance specifications during the warranty period will be replaced within 48 hours for critical applications, minimizing downtime in robotic production systems.

Technical support includes 24/7 access to ABB’s global team of robot communication specialists, who provide assistance with configuration, troubleshooting, and protocol integration. Online resources include detailed wiring diagrams, firmware update guides, and compatibility matrices with ABB robot controllers. Customers can opt for extended service contracts offering annual preventive maintenance, on-site support, and priority firmware updates, ensuring the ABB 3ASC25H215E DATX131 delivers reliable communication throughout its 8-year design lifespan.