Description

Key Technical Specifications

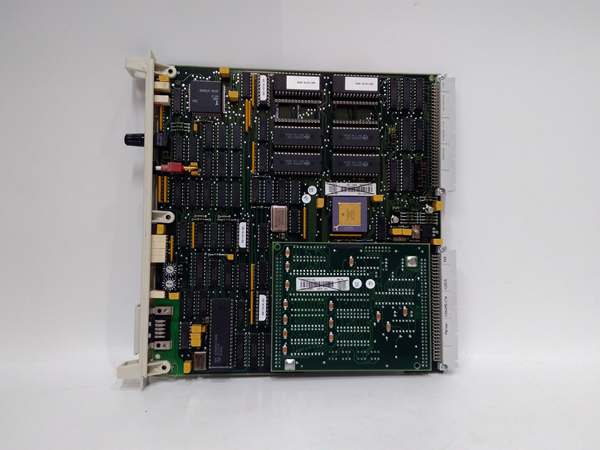

- Model Number: 216AB61 HESG324013R0100

- Manufacturer: ABB

- Compatible Systems: ABB Advant OCS, MasterPiece 200/300 Safety Controllers

- Input Configuration: 16 digital safety inputs (24V DC, dual-channel redundant), sinking/sourcing configurable

- Safety Certification: IEC 61508 (SIL 3), EN 954-1 (Category 4)

- Response Time: <10ms (input detection + fault reporting)

- Operating Temperature: -20°C to +60°C (-4°F to +140°F)

- Storage Temperature: -40°C to +85°C (-40°F to +185°F)

- Isolation: 2.5kV AC (channel-to-channel, channel-to-backplane, safety to non-safety)

- Power Supply: Derived from safety controller backplane (24V DC, 250mA typical)

- Protection Features: ESD protection (±25kV), short-circuit protection, cross-channel fault detection

- Dimensions (W x H x D): 105mm x 165mm x 125mm

- Weight: Approx. 520g

- Mounting: Rack-mount (Advant OCS safety I/O rack, tool-less installation)

- Compliance: IEC 61131-2, IEC 61000-4 (EMC), UL 1998 (safety)

- Status Indicators: Power (PWR), Channel OK (1–16), Safety Fault (RED), Module Health (GREEN)

ABB DSCS150 5752001-FY

Field Application & Problem Solved

In safety-critical industrial environments—refineries, chemical plants, and power stations—the biggest challenge is reliable monitoring of safety interlocks (e.g., emergency stops, door interlocks, pressure safety switches) while meeting SIL 3/Category 4 compliance. Legacy safety input modules lack redundant design, poor fault visibility, or inability to withstand harsh conditions, leading to false safety trips, unplanned downtime, or catastrophic safety hazards (e.g., unprotected machine starts, over-pressurization). This module solves that by combining high-density safety inputs with redundant circuitry, real-time fault detection, and SIL 3 certification—eliminating the compromises between safety, reliability, and system density.

You’ll typically find this module in Advant OCS safety controller racks monitoring critical interlocks: refinery reactor emergency stop (E-Stop) circuits, chemical plant hazardous area door interlocks, or power plant boiler flame detection safety loops. It’s also used in pulp mill digester pressure safety switches and water treatment plant chemical dosing interlocks, where a single input failure could lead to injury or environmental damage. For retrofits, it replaces outdated safety I/O modules in legacy Advant systems, upgrading to modern safety standards without replacing the entire safety controller—saving cost and avoiding operational disruption.

Its core value is safety integrity and fault transparency. The dual-channel redundant inputs ensure a single wire or component failure won’t trigger a false trip or mask a real safety issue. The <10ms response time ensures safety actions (e.g., shutdowns) happen instantaneously, while per-channel fault detection lets technicians pinpoint issues without taking the entire safety system offline. For plant operators, this translates to compliant, reliable safety monitoring, fewer unplanned safety trips, and faster troubleshooting—critical in industries where safety non-compliance carries severe regulatory and human costs.

Installation & Maintenance Pitfalls (Expert Tips)

Dual-Channel Wiring: Don’t Daisy-Chain Safety Inputs

Rookies often daisy-chain two safety devices onto a single dual channel, defeating the redundant design. Each dual channel is intended for a single safety device (e.g., E-Stop with two contacts) to detect wire breaks or contact failure. Wire each safety device’s redundant contacts to separate channels within the dual-channel pair. Test with a multimeter to confirm each channel responds independently—daisy-chaining eliminates fault detection and violates SIL 3 requirements.

Safety Grounding: Use Dedicated Safety Earth

The module’s safety circuits require a separate safety earth (PE) to maintain isolation and fault integrity. Technicians frequently share the safety ground with non-safety circuits, creating ground loops that trigger false faults. Connect the module’s safety ground terminal to a dedicated safety earth bus, not the chassis or signal ground. Ensure the safety earth resistance is <1Ω—high resistance compromises fault current dissipation and safety certification.

Configuration: Lock Safety Parameters (No Unauthorized Changes)

A common mistake is leaving safety parameters (e.g., input type, fault response) unlocked after commissioning. Unauthorized changes can degrade safety integrity or disable fault detection. Use the Advant OCS configuration software to lock safety parameters with a password. Document the password and restrict access to authorized safety engineers only—unlocked parameters are a top cause of safety system non-compliance during audits.

Periodic Testing: Verify Fault Detection (Don’t Skip It)

Rookies skip periodic functional testing of the module’s fault detection capabilities, relying on “passive” monitoring. Over time, component degradation or wiring issues can disable fault detection without triggering an alert. Test each channel quarterly by simulating a wire break or short-circuit. Verify the module reports the fault to the safety controller and initiates the correct response (e.g., no false shutdown, clear fault message). This testing is required to maintain SIL 3 certification and ensure the module works when needed.

ABB 216AB61 HESG324013R0100

Technical Deep Dive & Overview

The ABB 216AB61 HESG324013R0100 is a safety-critical digital input module engineered to monitor safety interlocks in high-integrity industrial systems. At its core, it uses dual-channel redundant circuitry for each input, ensuring a single point of failure (e.g., wire break, contact sticking) is detected and reported without compromising system safety. The module communicates with Advant OCS safety controllers via a dedicated safety backplane, ensuring low-latency data transfer (<10ms) for time-sensitive safety actions.

Each input channel features independent signal conditioning and isolation (2.5kV AC), preventing cross-talk between channels and protecting against electrical transients. The configurable sinking/sourcing inputs adapt to different safety device types (e.g., NPN/PNP interlock switches, E-Stop buttons) without hardware modifications. Built-in cross-channel fault detection identifies mismatched signals between dual-channel pairs, alerting the controller to wiring or device failures.

The module’s SIL 3 certification is achieved through redundant components, fault detection mechanisms, and compliance with IEC 61508. Battery-backed memory preserves safety configurations during power outages, ensuring no loss of safety integrity on restart. The status LEDs provide at-a-glance visibility into channel health and module status, while detailed fault codes are transmitted to the safety controller for remote monitoring.

Ruggedness is built for harsh industrial environments: the wide operating temperature range and robust enclosure withstand dust, vibration, and temperature extremes. The tool-less rack-mount design simplifies installation and replacement, while the high channel density (16 inputs) reduces the number of modules needed per safety rack—saving space and reducing failure points.

Overall, this module is a cornerstone of safety-critical control systems: it delivers the high integrity required for SIL 3 applications, the fault transparency needed for reliable operation, and the compliance essential for regulatory adherence—all while integrating seamlessly with legacy Advant OCS infrastructure.