Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | 1TGE120011R1111 |

| Manufacturer | ABB |

| Product category | AC contactor |

| Rated voltage (coil) | 230 V AC |

| Rated current (AC-3) | 63 A at 400 V AC |

| Number of poles | 3 (main contacts) + 1 NC auxiliary contact |

| Breaking capacity | 10 x rated current (AC-3) |

| Operating frequency | 50/60 Hz |

| Mechanical lifespan | Up to 10 million operations |

| Electrical lifespan | Up to 1 million operations (AC-3) |

| Operating temperature range | -25°C to +60°C (-13°F to +140°F) |

| Dimensions (LxWxH) | 90 mm x 70 mm x 105 mm (3.54 in x 2.76 in x 4.13 in) |

| Protection rating | IP20 (open type) |

| Installation type | DIN rail or panel mount |

| Certification | IEC 60947-4-1, CE, UL, CSA |

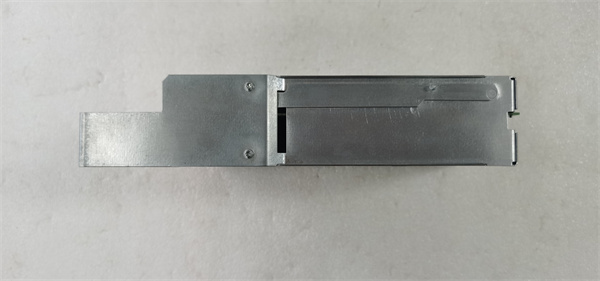

ABB 1TGE120011R1111

Product introduction

The ABB 1TGE120011R1111 is a reliable AC contactor designed for switching and controlling medium-sized electric motors and inductive loads in industrial and commercial applications. As part of ABB’s Tmax XT series, this contactor combines compact design with robust performance, making it a versatile choice for various power control scenarios.

ABB 1TGE120011R1111 serves as a key switching component in electrical circuits, enabling remote control of motors, pumps, fans, and heating systems. With a rated current of 63 A (AC-3) at 400 V AC, it is well-suited for loads up to 30 kW, making it ideal for applications ranging from manufacturing machinery to HVAC systems. Its 3-pole main contacts and 1 normally closed (NC) auxiliary contact provide flexibility in control logic, while the 230 V AC coil ensures compatibility with standard control circuits. Whether in new installations or retrofits, ABB 1TGE120011R1111 delivers consistent performance, contributing to the safety and efficiency of electrical systems.

Core advantages and technical highlights

Robust contact design: ABB 1TGE120011R1111 features silver-alloy contacts that resist arcing and wear, ensuring a long electrical lifespan of up to 1 million operations (AC-3). This durability reduces maintenance needs and minimizes downtime in high-cycle applications, such as conveyor systems or packaging lines.

Energy-efficient operation: The contactor’s optimized coil design reduces power consumption, with a holding power of ≤5 VA. This efficiency lowers energy costs, especially in systems where contactors remain energized for extended periods, aligning with sustainability goals in modern facilities.

Wide operational tolerance: ABB 1TGE120011R1111 operates reliably across a broad temperature range (-25°C to +60°C) and can handle voltage fluctuations of ±15% of the nominal coil voltage. This resilience ensures stable performance in harsh environments, including industrial workshops with varying ambient conditions.

Easy installation and integration: Designed for user convenience, ABB 1TGE120011R1111 supports tool-free DIN rail mounting and features quick-connect terminals, simplifying installation and reducing wiring time. Its compact dimensions (90 mm x 70 mm x 105 mm) save space in control panels, allowing for more efficient cabinet layouts.

Typical application scenarios

In commercial buildings, ABB 1TGE120011R1111 controls HVAC systems, managing fan motors and pumps to regulate airflow and temperature. Its NC auxiliary contact enables interlock functionality, preventing simultaneous operation of conflicting components (e.g., heating and cooling elements), enhancing system safety. The contactor’s energy efficiency also reduces the overall power consumption of building management systems.

Within food processing facilities, ABB 1TGE120011R1111 switches conveyor motors in packaging lines, handling the frequent start-stop cycles required for batch processing. Its ability to withstand temperature variations ensures reliable operation near refrigeration units or heat sources, while its robust contacts resist contamination from dust and moisture in washdown areas.

In industrial workshops, ABB 1TGE120011R1111 controls small to medium-sized machine tools, such as lathes and drills. Its fast switching capability (≤50 ms) ensures precise motor control, while the NC auxiliary contact integrates with emergency stop circuits to quickly disconnect power in hazardous situations, protecting operators and equipment.

ABB 1TGE120011R1111

Related model recommendations

ABB 1TGE120011R1121: A variant of ABB 1TGE120011R1111 with a 110 V AC coil, suitable for systems using lower control voltages.

ABB 1TGE120011R1211: A higher-rated contactor (95 A) than ABB 1TGE120011R1111, ideal for larger motors up to 45 kW at 400 V AC.

ABB TA25DU02: Thermal overload relay designed to pair with ABB 1TGE120011R1111, providing motor protection against overcurrent and phase imbalance.

ABB 1SBL457001R8000: Contactor accessory kit for ABB 1TGE120011R1111, including additional auxiliary contacts for expanded control logic.

ABB 1TLA020021R0000: A smaller contactor (40 A) in the same series as ABB 1TGE120011R1111, suitable for lighter loads up to 15 kW.

ABB 1SFL525001R1110: Surge protection device that complements ABB 1TGE120011R1111, shielding the contactor and connected equipment from voltage spikes.

ABB 1TGE120011R1100: DC coil version of ABB 1TGE120011R1111 (24 V DC), designed for systems with direct current control circuits.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing ABB 1TGE120011R1111, ensure the mounting surface (DIN rail or panel) is clean, flat, and secure, with at least 50 mm of clearance for wiring. Required tools include a screwdriver, torque wrench (set to 1.2 Nm for terminals), and wire strippers. Verify that the coil voltage matches the control circuit (230 V AC) and that the main circuit wiring is sized for 63 A (minimum 10 mm² copper). Ensure the contactor is de-energized during installation, and use appropriate personal protective equipment (insulated gloves, safety glasses).

Maintenance suggestions: For ABB 1TGE120011R1111, perform quarterly visual inspections to check for contact wear, dust accumulation, or loose connections. Clean contacts annually using a soft brush or compressed air (max 5 bar) to remove debris. Measure contact resistance periodically—values exceeding 100 mΩ indicate worn contacts that require replacement. Check the coil for overheating during operation (temperature rise should not exceed 60°C above ambient). If the contactor fails to operate, verify coil voltage and check for mechanical jamming; replace the coil or contacts with ABB-approved parts if faulty. Document all maintenance activities to track lifespan and performance trends.

Service and guarantee commitment

ABB 1TGE120011R1111 is backed by a 5-year warranty from the date of purchase, covering manufacturing defects and performance issues under normal operating conditions. ABB’s technical support team provides assistance via phone and email, with response times guaranteed within 24 hours for standard inquiries.

We offer application engineering services to help select the right contactor for your specific load requirements, ensuring optimal performance of ABB 1TGE120011R1111 in your system. Extended warranty options are available, including on-site inspection services. In the event of a warranty claim, ABB guarantees prompt replacement or repair, with genuine ABB components used to maintain original performance standards. Our commitment to quality ensures that ABB 1TGE120011R1111 meets the highest reliability and safety standards throughout its service life.