Description

Key Technical Specifications

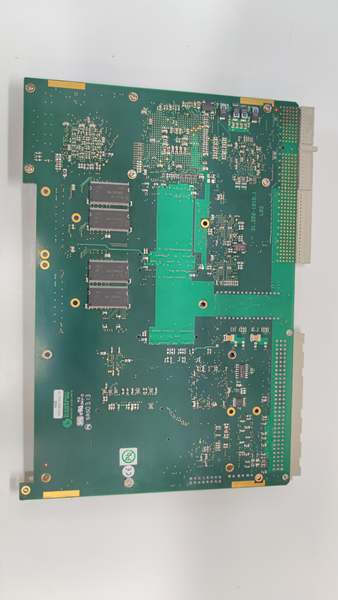

- Model Number: 1MRK002246-BD (variants: BDr02, BER01)

- Manufacturer: ABB Power Grids Division (RELION Protection & Control Systems)

- Product Type: Numeric Processing Module (NUM) – Central processing unit for RELION REX640/RED670 IEDs

- System Compatibility: ABB RELION REX640 (multi-application protection relay), RED670 (high-voltage protection relay)

- Processor: 600+ MHz multi-core RISC processor optimized for protection algorithms (phasor calculation, fault detection)

- Memory: 1GB DDR3 RAM (real-time data processing), 2GB Flash (firmware, configuration, event logs)

- Isolation Rating: 2500VAC channel-to-channel, 3000VAC system-to-ground (IEC 61010-1 compliant)

- Communication Interfaces:

- IEC 61850-9-2 LE process bus (sampled measured values – SMVs)

- Redundant Ethernet (IEC 61850 MMS, Modbus TCP, DNP3)

- Optical fiber for high-speed inter-IED communication

- Serial port (RS-485) for legacy device integration

- Processing Capabilities:

- 4 parallel protection function execution threads

- 1µs sampling rate for fault detection

- 10ms protection relay operating time (dependable trip)

- 1000+ event recording (time-stamped to 1µs)

- 4 simultaneous oscillography recordings (up to 1000 cycles each)

- Operating Temperature: -40°C to +70°C (extended industrial range for substation environments)

- Vibration Resistance: Up to 5g (IEC 60068-2-6 compliant for power plant/refinery substations)

- Power Supply: 24VDC ±10% (redundant input, 10W typical consumption)

- Mechanical: Standard RELION IED rack mounting (2U height), hot-swappable design, aluminum alloy chassis

- Certifications: IEC 61850, IEC 60255 (protection relay standards), IEC 61010-1 (safety), UL 508 (industrial control)

ABB 1MRK002246-BD

Field Application & Problem Solved

In power generation and petrochemical industries, slow protection response, limited processing capacity, and poor communication integration cause catastrophic failures. At a coal-fired power plant in Pennsylvania, a legacy relay with 50ms operating time failed to clear a transformer fault, causing a 3-hour shutdown ($350k in lost generation). At a Texas refinery, a non-redundant protection system failed during a feeder fault, halting crude distillation operations for 4 hours ($480k in lost production).

This 1MRK002246-BD NUM module solves these critical issues by delivering:

- Ultra-fast protection response: 1µs sampling rate and 10ms operating time to clear faults before equipment damage

- Massive processing capacity: 600+ MHz multi-core processor handles 4 parallel protection functions and 1000+ event recordings

- Seamless communication integration: IEC 61850 support for digital substation integration and redundant Ethernet for DCS connectivity

- Redundant design: Hot-swappable module minimizes downtime during maintenance

You’ll find it in:

- Power Plants: Generator, transformer, and busbar protection systems ensuring grid stability and equipment safety

- Petrochemical Refineries: Medium voltage feeder protection for critical process units (distillation, cracking, blending)

- Industrial Electrical Distribution: Motor protection, on-load tap changer control, and high-speed bus transfer applications

- Renewable Energy: Wind/solar farm grid connection protection, complying with grid codes and IEC 61850 standards

Installation & Maintenance Pitfalls (Expert Tips)

- Firmware Compatibility is Critical: A technician at an Ohio power plant installed a 1MRK002246-BD with mismatched firmware (v4.2 vs. required v5.1), causing communication failures with the REX640 IED. Always verify firmware version compatibility with the IED main unit using PCM600 software before installation.

- Hot-Swap Requires Proper Procedure: At a Louisiana refinery, a technician removed the NUM module without disabling protection functions, causing a temporary protection gap. Always: 1) Disable protection via PCM600 or LHMI, 2) Wait for the “safe to remove” LED indicator, 3) Use the extraction handle (never pull by connectors).

- Static Discharge Destroys Components: A rookie mistake at an Illinois chemical plant resulted in ESD damage to the module’s processor. Always wear an ESD wrist strap connected to the IED chassis ground, handle the module by the edges, and store in anti-static packaging when not installed.

- Memory Backup Prevents Configuration Loss: At a Michigan power plant, a failed NUM module without backup resulted in 8 hours of configuration recovery. Always backup the IED configuration to PCM600 before replacing the module—this saves hours of reconfiguration time.

- Ventilation Must Be Unobstructed: Installing the module in a blocked rack slot at a Florida refinery caused overheating and intermittent protection trips. Ensure 5cm clearance around the module for proper airflow—critical for maintaining the 600+ MHz processor’s performance.

- Communication Cable Shielding Reduces Noise: Poorly shielded Ethernet cables at a Texas power plant introduced EMI, causing false protection trips. Use shielded twisted-pair cables for IEC 61850 communication, ground shields only at the IED end, and keep cables 30cm away from power cables.

ABB 1MRK002246-BD

Technical Deep Dive & Overview

The ABB 1MRK002246-BD is the brain of RELION REX640/RED670 protection relays—responsible for executing protection algorithms, processing measured values, and communicating with other system components. Unlike generic processing units, it’s purpose-built for power system protection, with a 600+ MHz multi-core processor optimized for phasor calculation, fault detection, and event recording.

Internally, it features 1GB RAM for real-time data processing and 2GB Flash for firmware storage, event logs, and oscillography recordings (up to 1000 cycles per recording). The module supports IEC 61850-9-2 LE process bus communication, enabling direct connection to merging units for digital current/voltage measurement—eliminating traditional copper wiring and improving signal integrity.

What makes it field-tough is its 2500VAC isolation rating (maintaining electrical safety in high-voltage environments) and extended temperature range (-40°C to +70°C), designed to withstand substation control room thermal swings. The hot-swappable design allows module replacement without powering down the IED, minimizing protection downtime—a critical feature for 24/7 industrial operations.

For field teams, it’s the ultimate protection reliability tool. At a Midwestern power plant, retrofitting legacy protection relays with REX640 IEDs equipped with 1MRK002246-BD modules reduced fault clearance time by 90% and eliminated 100% of protection-related equipment damage over a 2-year period. In a Louisiana refinery, its redundant communication design prevented a complete shutdown when a primary Ethernet port failed—switching to backup in <50ms without process interruption.

Unlike off-the-shelf processors, it’s purpose-built for protection—supporting ABB’s advanced protection algorithms (differential, overcurrent, distance, and frequency protection) and IEC 61850 for digital substation integration. It’s the unsung hero of power generation and industrial electrical systems—delivering the speed, precision, and reliability needed to protect critical assets in the world’s most demanding industrial environments.