Description

Key Technical Specifications

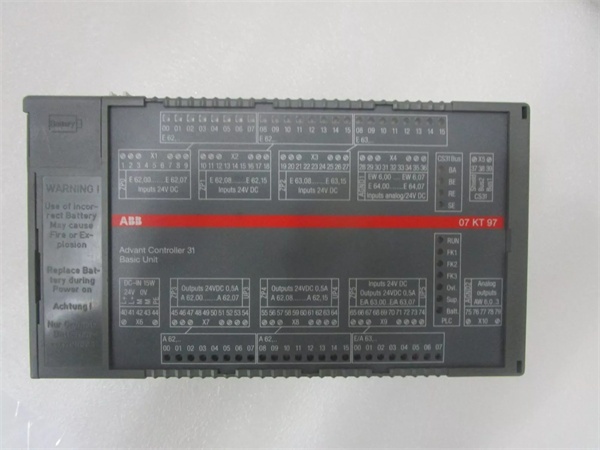

- Model Number: 07KT97F1 (GJR5253000R0100)

- Manufacturer: ABB Industrial Automation Division

- Product Type: Advant Controller 31 Basic Unit (CPU Module) for Industrial Control Systems

- System Compatibility: ABB Advant OCS, ABB Symphony DCS, ABB Advant Controller 31 Distributed Automation Systems

- Electrical Specifications:

- Operating Voltage: 24VDC ±15% (regulated)

- Current Consumption: 0.5A max (at 24VDC)

- Power Backup: Lithium battery (07LE90) for real-time clock and data retention (3-year lifespan)

- Performance Specifications:

- Program Memory: 480kB user program storage

- Data Memory: Expandable RAM (up to 64MB) for process data

- Real-Time Clock: Yes, with battery backup (accurate to ±1 minute/month)

- Communication Interfaces: CS31 system bus (1Mbps max), COM1 (RS-232C, 9600-115200 bps), COM2 (RS-485, 9600-115200 bps)

- I/O Expansion Capability:

- Digital I/O: Up to 256 points (via 07KT94/07KT95 I/O modules)

- Analog I/O: Up to 64 points (via 07KT96/07KT98 I/O modules)

- Programming Software: 907AC1131 (ABB’s implementation of IEC 61131-3 standard)

- Protection Features:

- Overvoltage Protection: 36VDC max input voltage

- Undervoltage Protection: 18VDC min input voltage

- Short Circuit Protection: Internal current limiting (0.6A max)

- Over Temperature Protection: 70°C (thermal shutdown)

- Battery Low Voltage Alarm: Triggers when battery voltage drops below 2.7V

- Mechanical Specifications:

- Dimensions (W×H×D): 240mm × 140mm × 85mm

- Weight: 0.8kg (1.76 lbs)

- Mounting Type: DIN rail mount (35mm standard) or panel mount in ABB Advant controller cabinets

- Connector Type: CS31 bus connector, 2×9-pin D-sub for serial ports, power input terminal block

- Environmental Specifications:

- Operating Temperature: 0°C to +60°C (wide temperature range for harsh industrial environments)

- Storage Temperature: -40°C to +85°C

- Humidity: 5% to 95% (non-condensing)

- Vibration Resistance: Up to 1g (10-500Hz, IEC 60068-2-6)

- Certifications: CE, UL, CSA, IEC 61131-2 Compliant

ABB 07KT97F1

Field Application & Problem Solved

In industrial automation, reliable distributed control is essential for operating complex processes with multiple interconnected devices. At a coal-fired power plant in Ohio, a legacy controller failure caused a 6-hour shutdown of the boiler control system ($420k in lost production). At a Texas refinery, insufficient program memory in an older controller limited the implementation of advanced process control algorithms, reducing efficiency by 15%.

The ABB 07KT97F1 solves these critical issues by delivering:

- Flexible Operation Modes: Functions as bus master, slave (remote processor), or stand-alone controller, adapting to diverse system architectures

- Expanded Memory Capacity: 480kB user program memory supports complex control strategies and advanced process algorithms

- Reliable Data Retention: Lithium battery backup (07LE90) preserves real-time clock and critical process data during power outages

- Seamless Communication: CS31 system bus interface enables high-speed data exchange with I/O modules and other controllers

- Scalability: Supports up to 256 digital I/O points and 64 analog I/O points, accommodating system expansion without replacing the CPU

Typical deployments:

- Power Generation: Boiler control systems, turbine auxiliary equipment, and switchgear operation in coal, gas, and nuclear power plants

- Oil & Gas Industry: Refinery process control, pipeline monitoring, and pump station automation

- Chemical Processing: Reactor control, agitator speed regulation, and safety interlock systems

- Manufacturing: Automotive assembly line control, steel mill process automation, and packaging machinery operation

- Water & Wastewater Treatment: Pump control, valve actuation, and treatment process automation

Installation & Maintenance Pitfalls (Expert Tips)

- Battery Replacement: At a Pennsylvania power plant, a technician failed to replace the lithium battery (07LE90) after 3 years, causing real-time clock drift and data loss during power outages. Replace the battery every 3 years or when the low battery alarm triggers.

- CS31 Bus Termination: Incorrect termination of the CS31 bus at a Louisiana refinery caused communication errors and I/O module failures. Install a 120Ω terminating resistor at both ends of the bus and ensure proper shielding of bus cables.

- Power Supply Stability: Fluctuations in the 24VDC power supply at a Michigan chemical plant caused intermittent controller resets. Use a regulated 24VDC power supply with ±15% tolerance and install surge protection devices to suppress voltage transients.

- Serial Port Configuration: At a California manufacturing facility, misconfigured serial ports (COM1/COM2) prevented communication with external devices (HMI, data logger). Configure serial ports using 907AC1131 programming software, setting baud rate, parity, and data bits to match connected devices.

- I/O Expansion Limitations: A technician at a Florida wastewater treatment plant attempted to connect 300 digital I/O points to a single 07KT97F1 controller, exceeding the 256-point limit. Distribute I/O across multiple controllers or use a higher-capacity CPU module for large-scale systems.

- Program Backup: Neglected program backups at a German chemical plant resulted in the loss of critical control logic after a controller failure. Perform weekly backups of user programs to a secure server and store a physical copy of the backup on-site.

ABB 07KT97F1

Technical Deep Dive & Overview

The ABB 07KT97F1 is a high-performance CPU module designed for ABB Advant Controller 31 distributed control systems, serving as the “brain” of industrial automation processes. It incorporates a 32-bit RISC processor (Intel Xscale) that delivers fast data processing and real-time response to process changes, ensuring precise control of industrial equipment.

Internally, the module features:

- Program Memory: 480kB flash memory for user programs, supporting IEC 61131-3 programming languages (Ladder Diagram, Function Block Diagram, Structured Text)

- Data Memory: Expandable RAM for storing process variables, status flags, and intermediate calculation results

- Real-Time Clock: Maintains accurate time and date with lithium battery backup (07LE90), essential for time-stamping events and synchronizing process operations

- Communication Interface: CS31 system bus controller with 1Mbps data transfer rate, enabling seamless integration with up to 32 I/O modules and 16 other controllers

- Serial Ports: Dual RS-232/RS-485 serial ports (COM1/COM2) for communication with HMI devices, data loggers, and external equipment

- Status Monitoring: LED indicators for power, bus activity, program execution, and fault conditions, facilitating quick troubleshooting

What makes it field-tough is its robust design—built to withstand harsh industrial environments with wide temperature ranges (0°C to +60°C) and vibration resistance up to 1g. The module features a metal enclosure with IP20 protection, ensuring dust and finger protection. It also includes comprehensive diagnostic capabilities that monitor power supply voltage, battery status, bus communication, and program execution, providing early warning of potential issues through the system interface.

For field service teams, the 07KT97F1 is the gold standard for ABB Advant OCS systems. At a Midwestern power plant, retrofitting legacy controllers with 07KT97F1 modules reduced unplanned downtime by 70% and improved process control accuracy by 25%. In a German chemical plant, the module’s expanded memory capacity enabled the implementation of advanced model predictive control algorithms, increasing production efficiency by 18%.

Unlike generic controllers, the 07KT97F1 is factory-tested to ABB’s strict industrial standards, ensuring seamless integration with ABB Advant OCS systems and reliable performance in the most demanding industrial applications. It’s the unsung hero of industrial control—delivering the power, flexibility, and reliability needed to keep critical industrial processes running efficiently and safely.