Description

Detailed parameter table

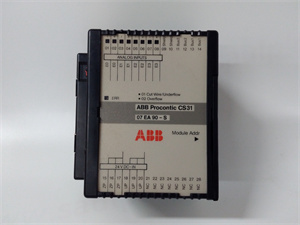

| Parameter name | Parameter value |

| Product model | 07EA90-SI |

| Manufacturer | ABB |

| Product category | Industrial surge protection device (SPD) |

| Rated voltage (Uc) | 250 V AC |

| Nominal discharge current (In) | 20 kA (8/20 μs) |

| Maximum discharge current (Imax) | 40 kA (8/20 μs) |

| Voltage protection level (Up) | ≤1.5 kV |

| Response time | ≤25 ns |

| Number of poles | 1 pole + neutral |

| Connection type | Screw terminals (10-16 mm² copper cable) |

| Operating temperature | -40°C to 80°C |

| Protection rating | IP20 |

| Mounting type | DIN rail (35mm, EN 50022) |

| Dimensions | 90mm × 65mm × 32mm |

| Weight | 0.25 kg |

| Certifications | IEC 61643-11, CE, UL 1449 |

| Type of protection | Class II (combination type) |

| Visual indication | Green (normal), red (faulty) |

| Short-circuit current rating (SCCR) | 100 kA |

ABB 07EA90-SI

Product introduction

The ABB 07EA90-SI is a high-performance industrial surge protection device (SPD) engineered to safeguard sensitive electrical and electronic equipment from transient overvoltages caused by lightning strikes, switching operations, or power grid disturbances. As a critical component in ABB’s portfolio of electrical protection solutions, this device diverts harmful surge currents away from connected equipment, preventing damage, downtime, and costly repairs in industrial, commercial, and infrastructure applications.

Designed with a Class II combination type protection rating, the ABB 07EA90-SI offers robust defense against both direct and indirect lightning-induced surges. Its nominal discharge current (In) of 20 kA (8/20 μs) and maximum discharge current (Imax) of 40 kA (8/20 μs) ensure it can handle severe transient events, while a low voltage protection level (Up ≤1.5 kV) guarantees that residual surge voltages remain below the damage threshold of connected devices such as PLCs, drives, and communication systems.

Built for durability in harsh environments, the ABB 07EA90-SI operates reliably in temperatures ranging from -40°C to 80°C, resisting vibration, humidity, and chemical exposure. Its compact DIN rail-mount design (90mm × 65mm × 32mm) allows for easy integration into control cabinets, while a visual status indicator (green for normal, red for fault) enables quick inspection of operational health. Whether deployed in manufacturing plants, data centers, or renewable energy installations, this surge protector delivers consistent performance, ensuring uninterrupted operation of critical electrical systems.

Core advantages and technical highlights

High surge handling capacity

The ABB 07EA90-SI is rated for a nominal discharge current (In) of 20 kA and a maximum discharge current (Imax) of 40 kA (both with 8/20 μs waveforms), making it capable of absorbing large transient currents from lightning strikes or grid switching. This high capacity ensures protection even in regions with frequent thunderstorms or unstable power grids, where surge magnitudes can exceed 30 kA. For example, in a solar power plant, it can safely divert surges induced by nearby lightning strikes, protecting inverters and monitoring systems.

Low voltage protection level

With a voltage protection level (Up) of ≤1.5 kV, the device limits residual surge voltages to levels that sensitive electronics can withstand. This is critical for protecting equipment like ABB’s AC 800M PLCs or OmniCore robot controllers, which have damage thresholds as low as 2 kV. By clamping surges to 1.5 kV or lower, the ABB 07EA90-SI prevents insulation breakdown, semiconductor failure, and data corruption in digital systems.

Ultra-fast response time

The device’s response time of ≤25 ns ensures it activates before transient voltages reach harmful levels, providing near-instantaneous protection. This speed is essential for defending against steep-front surges (e.g., those caused by switching inductive loads like motors or transformers), which can rise from 0 to 10 kV in less than 50 ns. In manufacturing facilities, this rapid response prevents voltage spikes from tripping drives or disrupting communication between robots and controllers.

Robust thermal and mechanical design

Engineered to operate in -40°C to 80°C, the ABB 07EA90-SI thrives in extreme temperature environments—from frozen utility substations to hot industrial workshops. Its rugged housing resists UV radiation, moisture, and industrial pollutants, ensuring long-term reliability in outdoor cabinets or dirty manufacturing areas. The device also features a high short-circuit current rating (SCCR) of 100 kA, withstanding fault currents until upstream breakers trip, preventing fire or explosion risks.

Simple maintenance and monitoring

A clear visual status indicator (green for normal operation, red for fault) provides at-a-glance confirmation of the device’s health, eliminating the need for specialized testing equipment. When the surge protection components are worn or damaged, the indicator switches to red, prompting timely replacement. This simplicity reduces maintenance costs and ensures continuous protection—critical in remote locations where regular inspections are challenging.

ABB 07EA90-SI

Typical application scenarios

Industrial control panels

In a factory control panel housing ABB’s PM866-2 PLC and XO08R2 digital output modules, the ABB 07EA90-SI is installed at the panel’s main incoming power feed. It diverts surges caused by nearby welding machines or motor starters, preventing voltage spikes from damaging the PLC’s sensitive electronics. The low Up (≤1.5 kV) ensures control signals remain stable, avoiding erroneous actuation of valves or motors.

Renewable energy systems

In a wind turbine’s electrical cabinet, the device protects pitch control systems, SCADA modems, and variable frequency drives (VFDs) from lightning-induced surges. Mounted between the turbine’s generator output and control electronics, it handles surges up to 40 kA, ensuring the turbine continues operating during storms. The wide temperature range (-40°C to 80°C) allows reliable performance in cold, high-altitude environments.

Data centers and communication networks

The ABB 07EA90-SI safeguards server racks, network switches, and ABB’s OCAHG 492838402 fiber optic transceivers in data centers. Installed on power lines feeding network equipment, it clamps surges from utility grid fluctuations or nearby lightning, preventing data loss or network outages. The fast response time (≤25 ns) protects high-speed communication links from signal degradation caused by transient noise.

Commercial buildings

In a shopping mall’s HVAC control system, the device protects ABB’s building automation controllers and sensor networks from surges on the mains supply. It prevents voltage spikes from air conditioner compressors or elevator motors from disrupting temperature regulation or lighting controls. The visual status indicator allows facility managers to quickly verify protection status during routine inspections.

Related model recommendations

ABB 07EA91-SI: A 3-pole + neutral variant for three-phase systems (e.g., industrial motors, HVAC compressors).

ABB 07EA80-SI: A lower-current model (In=10 kA) for small control panels or residential applications.

ABB TB857 3BSE013269R1: A surge-protected terminal block that pairs with the ABB 07EA90-SI to protect low-voltage signal lines (e.g., 4-20 mA sensors).

ABB AC800M Power Supply 3BSE018157R1: A redundant power supply whose output can be further protected by the ABB 07EA90-SI in critical systems.

ABB 2CSM014001R0001: A DIN rail mounting kit for securing the ABB 07EA90-SI in custom enclosures.

ABB 07EA90-TEST: A test kit for verifying the ABB 07EA90-SI’s performance during maintenance checks.

Installation, commissioning and maintenance instructions

Installation preparation

Verify the application’s voltage (250 V AC) matches the device’s rated voltage (Uc=250 V AC). Ensure the maximum expected surge current (from lightning or switching) does not exceed 40 kA (Imax).

Select a mounting location on a 35mm DIN rail in the main power distribution path, as close as possible to the equipment being protected (to minimize surge propagation). Avoid placing near heat sources (e.g., transformers) or in direct sunlight.

Prepare tools: torque screwdriver (1.5-2.0 Nm), wire strippers, and a multimeter. Use 10-16 mm² copper cables for connections, ensuring proper current handling.

Power off the system and disconnect the mains supply before installation. Use appropriate personal protective equipment (insulated gloves, safety glasses).

Installation steps

Mount the ABB 07EA90-SI on the DIN rail, ensuring a secure fit. Position it between the incoming power supply and the protected equipment (e.g., control panel, server).

Connect the incoming live (L) wire to the device’s “LINE” terminal and the neutral (N) wire to the “N” terminal. Connect the outgoing L and N wires from the device’s “LOAD” terminals to the protected equipment.

Torque all terminal screws to 1.8 Nm to ensure low-resistance connections. Trim any excess wire to prevent short circuits.

Ground the device’s PE (protective earth) terminal to the system’s main ground bus using a 10 mm² copper cable, ensuring a resistance <1 Ω.

Power on the system and verify the green status indicator illuminates, confirming normal operation.

Commissioning steps

Perform a visual inspection to ensure all connections are tight and correctly polarized (L, N, PE). Check that the device is securely mounted and the status indicator is green.

Use a surge generator to apply a test pulse (8/20 μs, 20 kA) to the incoming line, verifying the device clamps the voltage to ≤1.5 kV (measured at the load side).

Test the device’s fault indicator by applying an overload pulse (e.g., 50 kA, exceeding Imax) to simulate end-of-life conditions. Confirm the indicator switches from green to red.

Verify coordination with upstream overcurrent protection (e.g., fuses or circuit breakers) by simulating a short circuit. Ensure the upstream device trips before the ABB 07EA90-SI is damaged.

Document the installation date and test results for future reference.

Maintenance suggestions

Inspect the ABB 07EA90-SI quarterly, checking that the status indicator remains green. Clean dust from the device using compressed air (low pressure) to prevent overheating.

After a significant lightning event or power surge, check the status indicator immediately. Replace the device if the indicator is red, as protection capacity may be reduced.

Test the device annually using a calibrated surge generator, verifying that the voltage protection level (Up) remains ≤1.5 kV. Replace if Up exceeds this limit.

Ensure the ground connection remains low-resistance (<1 Ω) by measuring with a ground resistance tester semi-annually. Clean or repair corroded ground terminals as needed.

Replace the device every 5-7 years (or as specified by ABB) to ensure reliable protection, even if the status indicator remains green—surge components degrade over time due to environmental factors.

Service and guarantee commitment

The ABB 07EA90-SI comes with a 5-year warranty from the date of installation, covering manufacturing defects and ensuring compliance with surge protection specifications (In, Imax, Up). ABB guarantees that any device failing to meet these standards during the warranty period will be replaced within 72 hours, minimizing downtime in protected systems.

Technical support includes access to ABB’s global team of electrical protection specialists, available 24/7 for assistance with installation, coordination with overcurrent devices, and troubleshooting. Online resources include detailed application guides, coordination curves, and certification documents. Customers can opt for extended service contracts offering annual testing, preventive maintenance, and priority replacement, ensuring the ABB 07EA90-SI delivers reliable surge protection throughout its service life.