Description

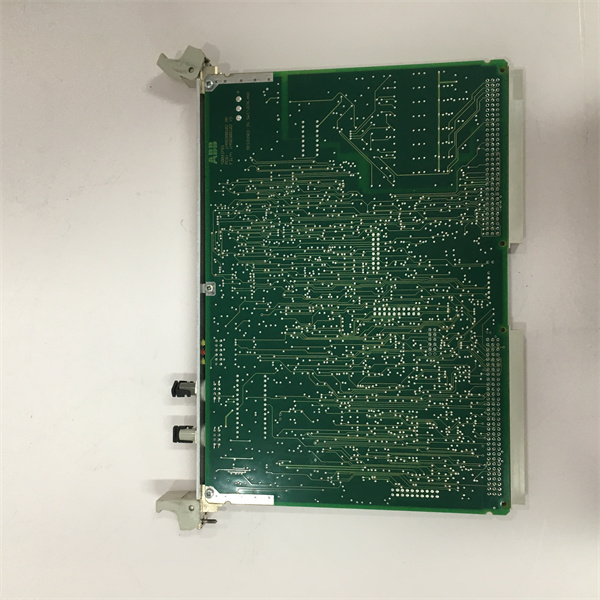

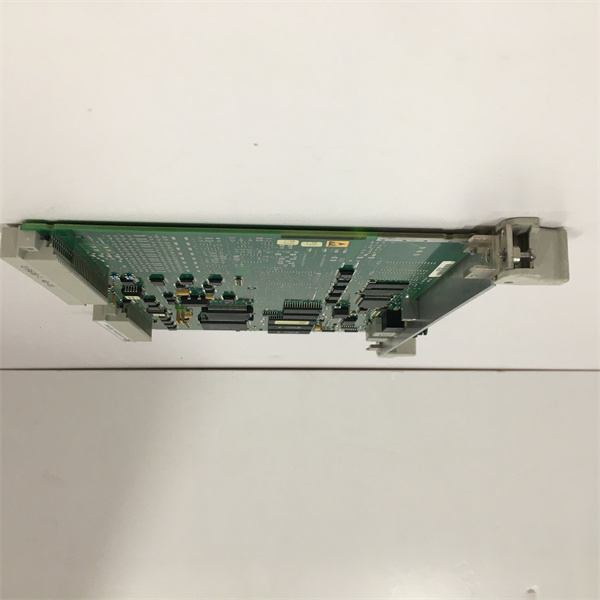

1. Product Description

2. Product Parameters

| Parameter | Details |

|---|---|

| Rated Voltage | 400 V AC (LV), 690 V AC (MV compatible) |

| Rated Current | 800 A (continuous), 1600 A (peak) |

| Trip Unit Type | Electronic (Micrologic 2.3A), adjustable for overload, short circuit, earth fault |

| Breaking Capacity | 50 kA at 400 V AC |

| Communication Interfaces | Modbus RTU, Profibus DP, Ethernet (optional) |

| Mounting Type | Fixed or 抽出式 (withdrawable) |

| Ambient Temperature | -25°C to +60°C (-13°F to +140°F) |

| Certifications | IEC 60947-2, UL 489, CE, ATEX (hazardous area compliant) |

500MBA02 1MRB150003R000/B

3. Advantages and Characteristics

- Intelligent Protection: The integrated Micrologic trip unit provides precise, adjustable protection settings, reducing false trips and minimizing downtime. For example, in a mining operation, the 500MBA02 detected a gradual overload in a conveyor motor and triggered a pre-alarm 30 minutes before a potential failure, allowing proactive maintenance and avoiding a 4-hour production halt.

- Remote Monitoring: With optional Ethernet connectivity, the breaker enables real-time tracking of motor health parameters (e.g., current, voltage, temperature), supporting predictive maintenance strategies and reducing manual inspection efforts by up to 50%.

- Compact Design: Despite its high current rating, the ABB 500MBA02 features a narrow width (100 mm), saving up to 30% panel space compared to older-generation breakers, making it suitable for retrofits in space-constrained environments.

- Safety Features: ABB’s patented “Test” position allows maintenance without power disconnection, while the isolated contact system prevents accidental live access during servicing.

4. Application Fields and Application Cases

- Manufacturing: Protects large motors in production lines (e.g., pumps, compressors, conveyor systems).

- Mining: Safeguards heavy-duty motors in crushers, ventilation systems, and ore processing equipment.

- Infrastructure: Used in water treatment plants, airports, and data centers for reliable motor control in critical systems.

A global food and beverage manufacturer deployed the ABB 500MBA02 in its bottling plant to manage 20+ motors in the packaging line. The breaker’s ability to integrate with the plant’s PLC via Profibus DP enabled centralized monitoring of motor performance. Over a year, this reduced unplanned downtime by 35% and improved energy efficiency by 12% through optimized motor start/stop cycles.

5. Competitor Comparison

Compared to similar motor breakers, the ABB 500MBA02 stands out for its advanced trip unit flexibility (supporting up to 10 customizable protection curves) and superior short-circuit withstand capability (100 kA peak). Its wide temperature range and ATEX certification make it a preferred choice for harsh environments, while the Emax 2 series’ common interface ensures easy interchangeability with other ABB breakers, reducing spares inventory costs by up to 20%.

500MBA02 1MRB150003R000/B

6. Selection Suggestions

- Voltage/Current Matching: Ensure the breaker’s rated voltage and current align with the motor’s full-load current (FLC) and system voltage, allowing a 20–25% margin for starting inrush currents.

- Communication Needs: Choose the appropriate interface (Modbus, Profibus, etc.) based on your plant’s existing automation network.

- Mounting Style: Opt for the withdrawable version for applications requiring frequent maintenance or quick replacement, while fixed mounts suit stable, low-maintenance setups.

- Environmental Compliance: Verify ATEX/IECEx certification if the installation site has explosive gas/dust hazards.

7. Precautions

- Installation: Ensure proper torque (8–10 N·m) for busbar connections and maintain adequate clearance (≥50 mm) around the breaker for heat dissipation.

- Wiring: Separate control cables from power cables to minimize electromagnetic interference (EMI), and use shielded cables for communication links.

- Trip Unit Calibration: Regularly validate trip settings against motor specifications using ABB’s DriveMate Mobile app or PC-based software.

- Maintenance Schedule: Perform annual insulation resistance tests and check for loose connections, especially in high-vibration environments like mining sites.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.