Description

Product Overview

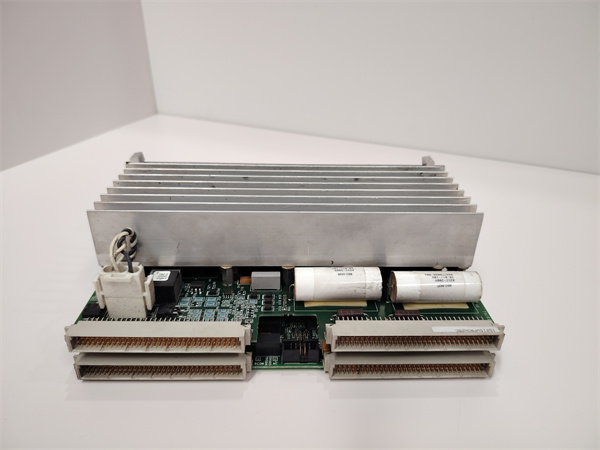

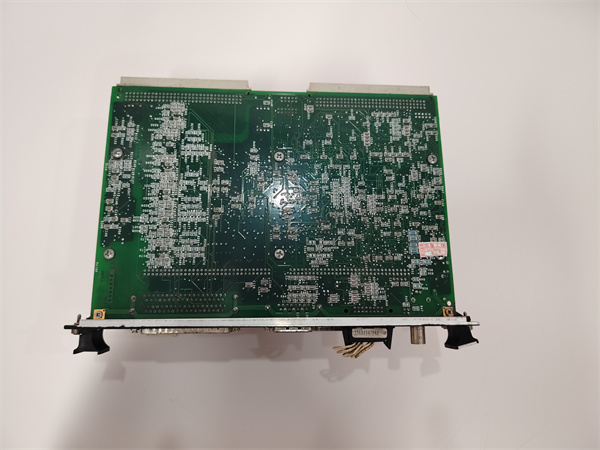

The GE VPROH2B IS215VPROH2BC is a highly advanced and reliable protection module designed specifically for steam and gas turbine control systems. As an integral part of GE’s industrial automation product portfolio, it plays a crucial role in safeguarding the safe and efficient operation of turbines.

At its core, the VPROH2B protection board is engineered to offer emergency overspeed (EOS) protection. It continuously monitors the turbine’s speed with high precision. In the event that the turbine’s speed exceeds the preset safety limits, it promptly triggers an emergency stop mechanism. This rapid response is vital as it effectively prevents potential equipment damage and safety accidents that could occur due to excessive speed.

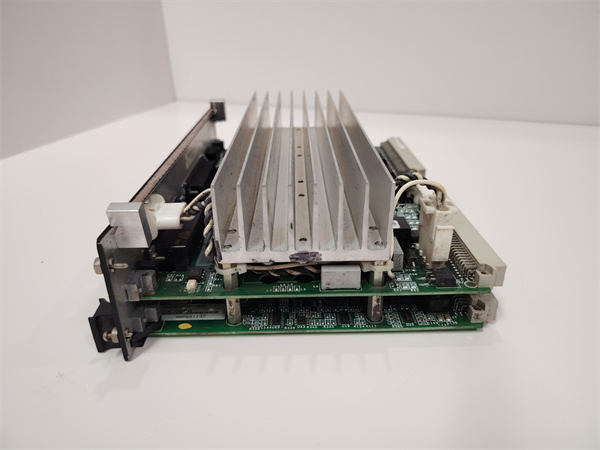

The IS215VPROH2BC is constructed with a redundant design, consisting of three redundant VPRO boards. This redundancy is a key feature that significantly enhances the system’s reliability and safety. Even if one of the boards encounters a malfunction, the other two can seamlessly continue to provide the necessary protection functions. This ensures that the turbine’s protection system remains operational at all times, minimizing the risk of system failures.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | VPROH2B IS215VPROH2BC |

| Manufacturer | GE |

| Product Type | Turbine Protection Module |

| Power Supply | 125V DC from cabinet PDM, internally converted to 5V and 28V DC |

| Operating Temperature | 0 – 45 °C |

| Memory | 16 MB of DRAM |

| Processor Type | Pentium |

| Level 2 Cache | 256 KB |

| Ethernet Interface | Thinwire 10base2 |

| Baud Rate | 19200 |

| Number of D – shell Ports | Five |

| Power Connector | Three – pin sub D connector |

| Redundancy System | Simplex or TMR |

| Frame Rate | Up to 100 Hz |

| MPU Input Circuit Sensitivity | Min. 27 mV peak at 2 Hz |

| Response Time for Solenoids | Solenoid L/R time constant at 0.1 sec |

| Trip Solenoids Quantity | Six per VPRO (three per TREG) |

VPROH2B IS215VPROH2BC

Main Features and Advantages

Precise Emergency Overspeed Protection

The GE VPROH2B IS215VPROH2BC offers highly accurate emergency overspeed protection. By using six passive magnetic speed sensors, it can precisely monitor the turbine’s speed. Through sophisticated control logic and algorithms, it can achieve both accurate speed control and effective overspeed protection. This level of precision helps in maintaining the optimal performance of the turbine and protecting it from the harmful effects of overspeed.

Redundant Design for High Reliability

The triple – redundant design of the IS215VPROH2BC is a major advantage. In case of a failure in one of the VPRO boards, the remaining two boards can take over the protection functions without any interruption. This redundancy significantly reduces the probability of system failures and downtime, ensuring the continuous and reliable operation of the turbine protection system.

Comprehensive Parameter Monitoring

In addition to speed monitoring, the module also has thermocouples and analog inputs. These allow it to monitor key parameters such as the gas turbine exhaust temperature. By keeping track of multiple critical parameters, the VPROH2B IS215VPROH2BC can provide a more comprehensive protection solution, enabling early detection of potential issues and taking appropriate actions to prevent major problems.

Effective Trip Function

The VPROH2B protection board works in tandem with the TREG and TRPG terminal boards. It can manage up to 12 relays and operate three trip solenoid valves through voting inputs. This coordinated operation of relays and solenoid valves enables the quick and reliable emergency tripping of the turbine when required, adding an extra layer of safety to the overall system.

Good Communication Capability

Equipped with an Ethernet connection, the protection module supports communication between the IONET and control modules. This enables seamless data transmission and instruction reception between the protection board and other components of the system. As a result, it enhances the overall integration and coordination of the entire control system, allowing for more efficient operation and management.

VPROH2B IS215VPROH2BC

Application Field

The GE VPROH2B IS215VPROH2BC is widely applied in industries where the reliable operation of turbines is of utmost importance. In the power generation sector, both in steam and gas – fired power plants, it is used to protect the turbines that generate electricity. By ensuring the safe operation of these turbines, it contributes to the stable supply of electricity.

In the oil and gas industry, turbines are used in various processes such as gas compression and power generation for offshore platforms. The VPROH2B IS215VPROH2BC is employed to safeguard these turbines, protecting valuable equipment and ensuring the smooth operation of the production process. Overall, any industry that relies on turbines, which require high – reliability and safety – critical protection systems, can benefit from the use of this advanced turbine protection module.

Related Products

- GE IS230TVBAH2A: A high – power dual – supply driver module. While the VPROH2B IS215VPROH2BC focuses on turbine protection, the IS230TVBAH2A is more about driving high – current applications. However, in some complex industrial setups, they might be used together. For example, in a large – scale power – generation facility, the IS230TVBAH2A could be powering certain components of the turbine system, while the VPROH2B IS215VPROH2BC ensures the overall protection of the turbine against overspeed and other hazards.

- GE IC697CPM925: A programmable logic controller (PLC) CPU module. The VPROH2B IS215VPROH2BC can interface with the IC697CPM925 in industrial control systems. The PLC can send control commands to the protection module based on various input signals, and the protection module can in turn provide feedback to the PLC about the turbine’s status. This interaction enables more comprehensive and automated control of the turbine system.

- GE DS200DMCBG1AED: A digital motion control board. In applications where the turbine’s motion needs to be precisely controlled in addition to being protected, the DS200DMCBG1AED can work in combination with the VPROH2B IS215VPROH2BC. For instance, in a turbine – driven manufacturing process, the motion control board can regulate the movement of certain turbine – related components, and the protection module can ensure the safety of the entire setup.

- GE VME – PMC – CADDY: A carrier module for PMC cards. The VPROH2B IS215VPROH2BC can potentially be integrated into a system that uses the VME – PMC – CADDY if there is a need to expand the system’s functionality. For example, if additional monitoring or communication capabilities are required for the turbine protection system, relevant PMC cards can be installed on the VME – PMC – CADDY and integrated with the VPROH2B IS215VPROH2BC.

- Upgraded Versions of VPROH2B IS215VPROH2BC (if available): These would likely come with enhanced features such as more advanced speed – monitoring algorithms, improved communication protocols, or better integration with newer turbine models. They can be used as a direct replacement for the existing VPROH2B IS215VPROH2BC in applications where performance upgrades are desired without major changes to the overall system architecture.

Installation and Maintenance

Pre – installation preparation: Before installing the GE VPROH2B IS215VPROH2BC, make sure to turn off all power sources related to the turbine control system to avoid electrical accidents. Carefully review the installation manual provided by GE, which contains detailed information on the proper positioning and connection of the module. Check the compatibility of the module with the existing system, including the power supply requirements, communication interfaces, and physical mounting space. Ensure that the environment where the module will be installed meets the specified temperature and humidity conditions. When handling the module, use anti – static equipment to prevent damage from electrostatic discharge.

Maintenance recommendations: Regularly inspect the GE VPROH2B IS215VPROH2BC for any signs of physical damage, such as cracks in the casing or loose connections. Monitor the status of the module through the front – panel LED indicator lights, which display information about its operation, failure, and diagnostic alarms. Check the communication interfaces periodically to ensure smooth data transfer. Keep the module clean from dust and debris, as these can affect its performance. If any issues are detected, refer to the GE – provided troubleshooting guide or contact GE’s technical support for assistance. Also, consider scheduling periodic firmware updates provided by GE to ensure the module has the latest features and security enhancements.

Maintenance recommendations: Regularly inspect the GE VPROH2B IS215VPROH2BC for any signs of physical damage, such as cracks in the casing or loose connections. Monitor the status of the module through the front – panel LED indicator lights, which display information about its operation, failure, and diagnostic alarms. Check the communication interfaces periodically to ensure smooth data transfer. Keep the module clean from dust and debris, as these can affect its performance. If any issues are detected, refer to the GE – provided troubleshooting guide or contact GE’s technical support for assistance. Also, consider scheduling periodic firmware updates provided by GE to ensure the module has the latest features and security enhancements.

Product Guarantee

GE offers a comprehensive product guarantee for the GE VPROH2B IS215VPROH2BC. The module typically comes with a standard warranty period, during which GE will repair or replace the module free of charge if it is found to have defects in materials or workmanship. GE also provides professional technical support to assist customers with installation, configuration, and troubleshooting. Their team of experienced engineers is available to answer any questions related to the module and help customers optimize its performance in their specific turbine control applications. This commitment to quality and after – sales support gives customers the confidence to rely on the GE VPROH2B IS215VPROH2BC for their critical turbine protection needs.