Description

Product Overview

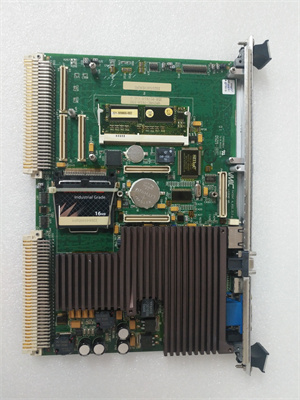

The GE VMIVME2540 is a high – performance intelligent counter controller module, designed as part of GE’s industrial automation product lineup. Engineered for seamless integration into industrial systems, this module plays a pivotal role in applications where precise event counting and control are crucial. It features a VMEbus slave interface, allowing for efficient communication and data transfer within the system.

The VMIVME2540 has an impressive event counting capacity of up to 4 giga events, making it suitable for complex industrial scenarios. It comes with 24 discrete output channels, each offering a 12 – bit resolution. These channels can source and sink up to 10 milliamperes at ±10 V, providing reliable and accurate signal output. For offline testing, its analog inputs can be disconnected from external circuitry, ensuring safety and accurate results. Whether in large – scale manufacturing plants or intricate industrial processes, the GE VMIVME2540 is a reliable solution for enhancing system performance and control accuracy.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | VMIVME2540 |

| Manufacturer | GE |

| Product Type | Intelligent Counter Controller Module |

| Interface | VMEbus slave |

| Counting Capacity | Up to 4 giga events |

| Number of Output Channels | 24 discrete |

| Output Channel Resolution | 12 – bit |

| Output Current | Up to 10 mA (source and sink) at ±10 V |

| Input Disconnection Feature | Yes, for analog inputs |

| Digital Signal Channels | 4, 8, 16, or 24 available for measurement and generation |

| Timing Controllers | Integrated system timing controllers |

| Interface Logic | Associated interface logic |

| Operating Temperature | – 40 °C to + 85 °C |

| Power Requirements | +5 V: 2.9 A; +3.3 V: 1.9 A; 12 V: 0.1 A |

| Dimensions | 6U VMEbus form factor (233.35 mm x 160 mm) |

IS215UCVGM06A IS215UCVGH1A VMIVME-7666-111000

Main Features and Advantages

High – Precision Counting: The VMIVME2540 can accurately count up to 4 giga events, ensuring that in applications such as high – speed production line monitoring or complex data acquisition, every event is precisely registered. This high – precision counting is essential for maintaining product quality and process efficiency in industrial settings.

Flexible Channel Configuration: With the option to select 4, 8, 16, or 24 channels for digital signal measurement and generation, it can adapt to different system requirements. For example, in a small – scale industrial control system, a lower number of channels might be sufficient, while a large – scale factory automation setup may require the full 24 – channel configuration.

Reliable Output Performance: The 24 discrete output channels, each with a 12 – bit resolution and the ability to handle up to 10 mA at ±10 V, offer stable and accurate signal output. This is crucial for driving actuators, relays, or other devices in industrial automation, ensuring consistent operation.

Offline Testing Capability: The ability to disconnect analog inputs from external circuitry during offline testing safeguards the module and the testing equipment. It also allows for more accurate testing, free from external interference, which is beneficial for maintenance and troubleshooting.

Flexible Channel Configuration: With the option to select 4, 8, 16, or 24 channels for digital signal measurement and generation, it can adapt to different system requirements. For example, in a small – scale industrial control system, a lower number of channels might be sufficient, while a large – scale factory automation setup may require the full 24 – channel configuration.

Reliable Output Performance: The 24 discrete output channels, each with a 12 – bit resolution and the ability to handle up to 10 mA at ±10 V, offer stable and accurate signal output. This is crucial for driving actuators, relays, or other devices in industrial automation, ensuring consistent operation.

Offline Testing Capability: The ability to disconnect analog inputs from external circuitry during offline testing safeguards the module and the testing equipment. It also allows for more accurate testing, free from external interference, which is beneficial for maintenance and troubleshooting.

Application Field

Manufacturing Industry: In manufacturing plants, the VMIVME2540 can be used to count the number of products passing through a conveyor belt, control the operation of robotic arms based on counted events, or synchronize the start – stop of multiple machines. For instance, in an automotive assembly line, it can precisely count the number of parts installed, ensuring quality control.

Industrial Automation Systems: In complex industrial automation setups, this module can be integrated into a larger control system. It can monitor and control various processes, such as the filling of containers in a food and beverage factory, where accurate counting of filled containers and control of the filling process are essential.

Military and Aerospace: In military and aerospace applications, the VMIVME2540‘s high – precision counting and reliable performance are highly valued. It can be used in flight control systems to count sensor events or in military equipment to control the firing sequence of weapons, where split – second accuracy is crucial.

Industrial Automation Systems: In complex industrial automation setups, this module can be integrated into a larger control system. It can monitor and control various processes, such as the filling of containers in a food and beverage factory, where accurate counting of filled containers and control of the filling process are essential.

Military and Aerospace: In military and aerospace applications, the VMIVME2540‘s high – precision counting and reliable performance are highly valued. It can be used in flight control systems to count sensor events or in military equipment to control the firing sequence of weapons, where split – second accuracy is crucial.

VMIVME-7750 VMIVME-7750-834 350-027750-834 D

Related Products

VMIVME – 7807 RC: A single – board computer by GE. It can work in tandem with the VMIVME2540 in an industrial system. The VMIVME – 7807 RC may handle more general – purpose computing tasks, while the VMIVME2540 focuses on event counting and control, together providing a comprehensive solution for industrial automation.

IC660ELB921M: A single – slot PCIM card from GE. It may be used to expand the functionality of the system where the VMIVME2540 is installed. For example, it could enhance the communication capabilities or provide additional processing power to support the operations of the VMIVME2540.

GE FANUC VMIVME – 2540 – 200: Similar to the VMIVME2540, it is also an intelligent counter/controller. However, it might have some differences in specific features or performance parameters, such as potentially different power requirements or additional software – based functions, which could make it more suitable for certain niche applications.

MVME 5100: A single – board computer by Motorola. Although from a different manufacturer, in some industrial setups, it could be an alternative to the VMIVME – 7807 RC and may be used in combination with the VMIVME2540 in systems that require a different set of computing capabilities.

140CPU11303: A processor by Schneider. In some multi – vendor industrial control systems, this processor might be used in a system where the VMIVME2540 is also present. It could be responsible for overall system coordination, with the VMIVME2540 handling the event counting and related control tasks.

IC660ELB921M: A single – slot PCIM card from GE. It may be used to expand the functionality of the system where the VMIVME2540 is installed. For example, it could enhance the communication capabilities or provide additional processing power to support the operations of the VMIVME2540.

GE FANUC VMIVME – 2540 – 200: Similar to the VMIVME2540, it is also an intelligent counter/controller. However, it might have some differences in specific features or performance parameters, such as potentially different power requirements or additional software – based functions, which could make it more suitable for certain niche applications.

MVME 5100: A single – board computer by Motorola. Although from a different manufacturer, in some industrial setups, it could be an alternative to the VMIVME – 7807 RC and may be used in combination with the VMIVME2540 in systems that require a different set of computing capabilities.

140CPU11303: A processor by Schneider. In some multi – vendor industrial control systems, this processor might be used in a system where the VMIVME2540 is also present. It could be responsible for overall system coordination, with the VMIVME2540 handling the event counting and related control tasks.

Installation and Maintenance

Pre – installation preparation: Before installing the VMIVME2540, ensure that the power to the system is turned off. Check the VMEbus slot where it will be installed for any signs of damage or debris. Verify that the power supply meets the module’s requirements of +5 V: 2.9 A; +3.3 V: 1.9 A; 12 V: 0.1 A. Also, make sure the operating environment temperature is within the specified range of – 40 °C to + 85 °C.

Maintenance recommendations: Regularly inspect the VMIVME2540 for any signs of physical damage, such as cracked circuit boards or loose connections. Check the counting accuracy periodically by running test scenarios. Clean the module gently to prevent dust accumulation, as dust can affect its performance. If any issues are detected, refer to the product manual for troubleshooting steps or contact GE’s technical support for assistance.

Maintenance recommendations: Regularly inspect the VMIVME2540 for any signs of physical damage, such as cracked circuit boards or loose connections. Check the counting accuracy periodically by running test scenarios. Clean the module gently to prevent dust accumulation, as dust can affect its performance. If any issues are detected, refer to the product manual for troubleshooting steps or contact GE’s technical support for assistance.

Product Guarantee

GE offers a comprehensive product guarantee for the VMIVME2540. The module comes with a standard warranty, typically covering manufacturing defects for a specified period. In case of any problems during this time, GE will provide repair or replacement services free of charge. Their global network of technical support teams is always available to assist customers. Whether it’s answering questions about installation, configuration, or helping with troubleshooting, GE’s experts are committed to ensuring that the VMIVME2540 operates smoothly. This reflects GE’s confidence in the quality and reliability of the product, giving customers peace of mind when using it in their industrial applications.