Description

Product Overview

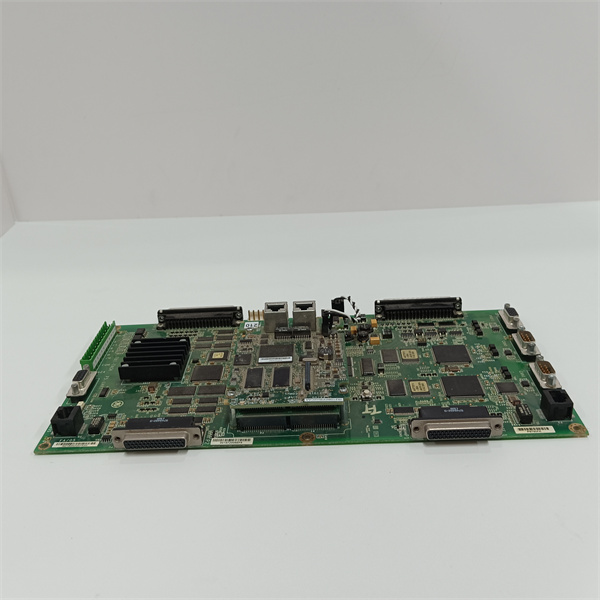

The GE VMIVME – 2540 – 300 is an intelligent counter/controller module from General Electric, designed specifically for VMEbus systems. As a VMEbus slave I/O module, it occupies a crucial position in industrial automation setups, offering a wide array of functions to enhance system performance.

This module provides high – precision digital measurement and function generation capabilities. With an on – board 15 MHz 68HC000 CPU, it can efficiently handle complex tasks. It has the ability to count up to 4 giga events, making it suitable for applications where accurate event tracking is essential. The GE VMIVME – 2540 – 300 also offers programmed output with up to 24 discrete outputs, allowing for precise control over connected devices. Additionally, it adheres to the ANSI/IEEE standard 754 – 1985 for 32 – bit floating – point arithmetic, ensuring reliable numerical operations. It serves as a reliable solution for industries seeking to optimize their data acquisition, process control, and machine control operations within VMEbus – based systems.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | VMIVME – 2540 – 300 |

| Manufacturer | General Electric |

| Product Type | Intelligent Counter/Controller Module |

| Interface | VMEbus slave interface |

| Event Counting Capacity | Up to 4 giga events |

| Programmed Outputs | Up to 24 discrete outputs |

| On – board CPU | 15 MHz 68HC000 |

| Arithmetic Standard | ANSI/IEEE 754 – 1985 for 32 – bit floating – point |

| Input Voltage Range | [Specify in product manual] |

| Operating Temperature | – 40 °C to + 60 °C |

| Storage Temperature | – 40 °C to + 80 °C |

| Dimensions | [Specify height, width, depth in product manual] |

| Weight | [Specify in product manual] |

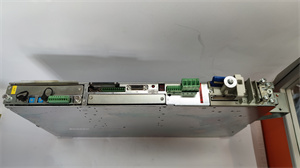

VME-PMC-CADDY

Main Features and Advantages

High – Precision Counting: The GE VMIVME – 2540 – 300 can accurately count up to 4 giga events. This high – precision event counting is invaluable in applications such as manufacturing process monitoring, where every occurrence of an event, like a part passing a sensor, needs to be precisely tallied for production efficiency and quality control.

Flexible Output Configuration: With up to 24 discrete outputs, the module offers great flexibility in controlling external devices. In an industrial automation line, these outputs can be used to activate different actuators, solenoid valves, or relays, enabling complex control sequences.

On – board Processing Power: The 15 MHz 68HC000 on – board CPU reduces the burden on the main system processor. It can independently perform tasks related to digital measurement and function generation, enhancing the overall system’s speed and efficiency. For example, in a data acquisition system, it can quickly process incoming signals without overloading the central controller.

Standard – Compliant Arithmetic: By following the ANSI/IEEE 754 – 1985 standard for 32 – bit floating – point arithmetic, the GE VMIVME – 2540 – 300 ensures consistent and accurate numerical computations. This is crucial in applications that require precise calculations, such as in scientific research or high – precision manufacturing processes.

Flexible Output Configuration: With up to 24 discrete outputs, the module offers great flexibility in controlling external devices. In an industrial automation line, these outputs can be used to activate different actuators, solenoid valves, or relays, enabling complex control sequences.

On – board Processing Power: The 15 MHz 68HC000 on – board CPU reduces the burden on the main system processor. It can independently perform tasks related to digital measurement and function generation, enhancing the overall system’s speed and efficiency. For example, in a data acquisition system, it can quickly process incoming signals without overloading the central controller.

Standard – Compliant Arithmetic: By following the ANSI/IEEE 754 – 1985 standard for 32 – bit floating – point arithmetic, the GE VMIVME – 2540 – 300 ensures consistent and accurate numerical computations. This is crucial in applications that require precise calculations, such as in scientific research or high – precision manufacturing processes.

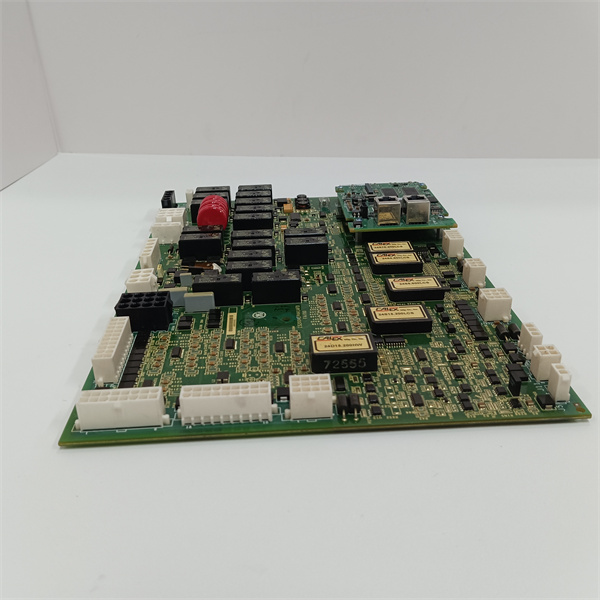

IS200AEPAH1ACB

Application Field

In industrial manufacturing, the GE VMIVME – 2540 – 300 is used in production lines for monitoring and controlling various processes. For instance, in an automotive assembly plant, it can count the number of parts being assembled, and based on the count, trigger actions like activating robotic arms to perform specific tasks. It can also control the speed and operation of conveyor belts by sending signals through its discrete outputs.

In the test and measurement industry, this module is deployed in automated test equipment. It can accurately count the number of pulses from sensors during product testing, and generate control signals to adjust test parameters. For example, in the testing of electronic components, it can count the number of electrical pulses a component emits under certain conditions and use its outputs to control the power supply or data acquisition settings of the test setup.

Power generation facilities also benefit from the GE VMIVME – 2540 – 300. It can be used to monitor the number of revolutions of turbines (by counting encoder pulses) and control auxiliary equipment such as cooling fans or lubrication pumps through its discrete outputs, ensuring the stable operation of power – generating machinery.

Related Products

- GE VMIVME – 2540: A base model of the series, likely with similar core functionality but may lack some of the specific configurations or optimizations of the VMIVME – 2540 – 300. It might have different channel options or less processing power, suitable for less demanding applications.

- GE VMIVME – 2550: Another module in the VMIVME series, which could have enhanced features such as more advanced communication capabilities or additional input/output options. It may be designed for applications that require higher – speed data transfer or more complex I/O operations compared to the GE VMIVME – 2540 – 300.

- GE VMEbus Backplanes: These are essential components for connecting the GE VMIVME – 2540 – 300 to other VMEbus modules in a system. They provide the electrical and mechanical connections, ensuring proper communication and power distribution within the VMEbus – based setup.

- GE Industrial Controllers: These controllers can work in tandem with the GE VMIVME – 2540 – 300. They can receive data from the module and use it to make control decisions, coordinating the overall operation of industrial processes.

- Signal Conditioning Modules: These modules can be used in conjunction with the GE VMIVME – 2540 – 300 to improve the quality of incoming signals. They can filter out noise, adjust signal levels, and perform other conditioning tasks, ensuring that the module receives clean and accurate signals for measurement and control.

Installation and Maintenance

Pre – installation preparation: Before installing the GE VMIVME – 2540 – 300, ensure that the VMEbus system is powered off to prevent electrical accidents. Check the module for any visible signs of damage during transit, such as bent pins or cracked components. Verify that the installation slot in the VMEbus backplane is clean and free of debris. Also, make sure that the power supply to the VMEbus system can meet the power requirements of the GE VMIVME – 2540 – 300 as specified in the product manual.

Maintenance recommendations: Regularly monitor the GE VMIVME – 2540 – 300 for any signs of overheating, such as discolored components or unusual smells. Check the event logs (if available) to identify any errors or abnormal operations. Clean the module periodically to remove dust, especially in environments with high particulate matter. If any issues are detected, refer to the product manual for troubleshooting steps. For more complex problems, contact GE’s technical support for assistance to ensure the continued reliable operation of the module.

Maintenance recommendations: Regularly monitor the GE VMIVME – 2540 – 300 for any signs of overheating, such as discolored components or unusual smells. Check the event logs (if available) to identify any errors or abnormal operations. Clean the module periodically to remove dust, especially in environments with high particulate matter. If any issues are detected, refer to the product manual for troubleshooting steps. For more complex problems, contact GE’s technical support for assistance to ensure the continued reliable operation of the module.

Product Guarantee

GE offers a comprehensive product guarantee for the GE VMIVME – 2540 – 300. Typically, it comes with a standard one – year warranty against defects in materials and workmanship. During this period, if the module shows any signs of malfunction due to manufacturing flaws, GE will provide repair or replacement services free of charge. Their dedicated technical support team is available to assist customers with installation guidance, configuration advice, and troubleshooting throughout the product’s lifespan. This commitment reflects GE’s confidence in the reliability and quality of the GE VMIVME – 2540 – 300, giving customers peace of mind when using it in their industrial applications.