Description

Product Overview

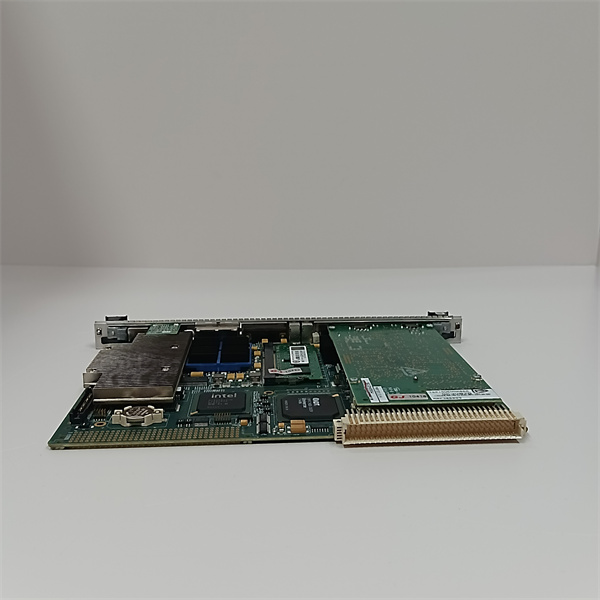

The GE IS215UCCAH3A is a printed circuit board (PCB) integral to the GE Mark VI Speedtronic Series. As a UCCx Controller, it plays a pivotal role in the automation system. This component is a CompactPCI (cPCI) single – board computer, designed to execute application code with high efficiency. Running on the QNX Neutrino operating system, renowned for its high – speed and high – reliability multitasking capabilities in industrial applications, the IS215UCCAH3A offers seamless operation. It is a key computing engine within the Mark VI controller, enabling effective management of heavy – duty gas and steam turbines. Mounted in a cPCI enclosure, it communicates with its I/O packs via onboard network interfaces, ensuring smooth data flow and control within the system.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS215UCCAH3A |

| Manufacturer | GE |

| Product Type | Control Module |

| Processor | 650 MHz Intel Celeron |

| Ethernet Port | 10BaseT/100BaseTX for UDH connectivity |

| Mezzanine Card Slots | 2 |

| Status LEDs | 4 |

| Communication Ports | 2 COM ports |

| Operating Temperature | 0 to 60 degrees Celsius |

| Cooling Method | Air – cooled by fan at bottom of cPCI rack |

| CMOS Power Source | Lithium battery (10 – year service life) |

VMICPCI-7632-03310 IS215UCCAH3A 350-657362-003310J

Main Features and Advantages

Reliable Processing Power: The GE IS215UCCAH3A comes equipped with a 650 MHz Intel Celeron processor. This ensures that it can handle complex application code running on the QNX Neutrino operating system without a hitch, providing reliable performance for continuous operation in industrial settings.

Efficient Communication: With its 10BaseT/100BaseTX ethernet port for connectivity to the Unit Data Highway (UDH), the IS215UCCAH3A enables fast and stable data transfer between the controller and other components in the system. The two COM ports further enhance its communication capabilities, allowing for connection with a variety of devices.

Convenient Physical Design: The board has two slots for mezzanine cards on its front faceplate, providing expandability options. Additionally, it has ejectors and injectors, though it’s crucial to lock the injectors after board insertion to ensure proper booting. The presence of status LEDs also allows for easy monitoring of the board’s operational status.

Efficient Communication: With its 10BaseT/100BaseTX ethernet port for connectivity to the Unit Data Highway (UDH), the IS215UCCAH3A enables fast and stable data transfer between the controller and other components in the system. The two COM ports further enhance its communication capabilities, allowing for connection with a variety of devices.

Convenient Physical Design: The board has two slots for mezzanine cards on its front faceplate, providing expandability options. Additionally, it has ejectors and injectors, though it’s crucial to lock the injectors after board insertion to ensure proper booting. The presence of status LEDs also allows for easy monitoring of the board’s operational status.

Application Field

The GE IS215UCCAH3A finds extensive use in power generation plants. In gas and steam turbine control systems, it serves as a core controller within the Mark VI Speedtronic Series. Here, it manages the operation of turbines, ensuring optimal performance, efficiency, and safety. For instance, it can precisely regulate the speed and power output of turbines based on real – time data from sensors. In oil and gas refineries, the IS215UCCAH3A is used to control various processes. It can manage the operation of pumps, compressors, and other critical equipment, helping to maintain the smooth flow of operations and prevent potential breakdowns. Overall, its application in these industrial scenarios is vital for maintaining the integrity and productivity of complex industrial processes.

Related Products

- GE IS215UCCAM03A: This is a CompactPCI (CPCI) board assembly that combines an IS215UCCAH3A with additional components like 128 MB of flash memory, 128 MB of DRAM, and the IS200EPMC. It offers enhanced memory capabilities compared to the base IS215UCCAH3A.

- GE IS215UCVEH2A: A PCB component for the GE Mark VI Speedtronic Series functioning as a VME controller card. It has a 300 MHz Intel Celeron processor, different from the 650 MHz in IS215UCCAH3A, and serves a slightly different control function within the Mark VI system.

- GE Mark VI Series Modules: This encompasses a range of modules that work in tandem with the IS215UCCAH3A to control and monitor gas and steam turbines, each contributing to different aspects of the overall system operation.

- GE CPCI Enclosures: These enclosures are where the IS215UCCAH3A and other related boards are mounted, providing a suitable physical environment for their operation.

- GE Turbine Sensors: These sensors feed data to the IS215UCCAH3A, enabling it to make informed control decisions in turbine – related applications.

VMICPCI-7632-03310 IS215UCCAH3A 350-657362-003310J

Installation and Maintenance

Pre – installation preparation: Before installing the GE IS215UCCAH3A, ensure that the CPCI enclosure is properly prepared. Check for any physical damage to the enclosure and clean it if necessary. Verify that all the required jumper settings on the IS215UCCAH3A board are correctly configured as per the manufacturer’s guidelines in user guides and manuals. Also, make sure that the lithium battery on the board, which powers the CMOS, is in good condition.

Maintenance recommendations: Regularly monitor the operating temperature of the IS215UCCAH3A as it should remain within the 0 – 60 degrees Celsius range. Check the status LEDs on the board to identify any potential issues. Since the board is air – cooled by a fan at the bottom of the CPCI rack, ensure that the fan is working properly. If the fan fails, it can lead to overheating and potential damage to the controller. Periodically review the jumper settings to confirm they haven’t been accidentally changed.

Product Guarantee

We stand firmly behind the quality of the GE IS215UCCAH3A. With a comprehensive quality assurance process in place, we ensure that each unit meets the highest industry standards. In case of any product – related issues, our dedicated after – sales service team is committed to providing prompt assistance. We offer technical support to help users with installation, configuration, and any operational queries. Our goal is to guarantee that the IS215UCCAH3A functions optimally throughout its lifespan, reflecting our confidence in the product’s design and manufacturing quality, and our commitment to customer satisfaction.