Description

Product Overview

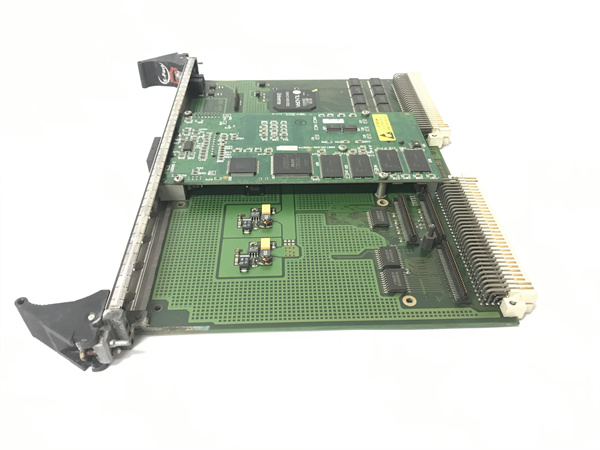

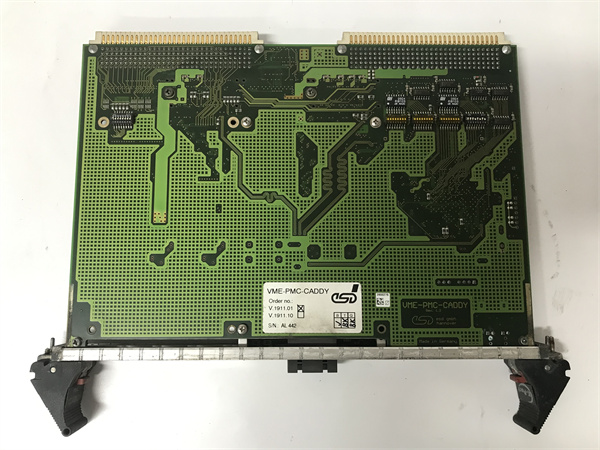

The GE VME-PMC-CADDY is a specialized carrier module designed by GE, playing a crucial role in the VME (VersaModule Eurocard) – based industrial automation and control systems. As an integral part of GE’s industrial control product lineup, the VME-PMC-CADDY is engineered to provide a reliable and efficient platform for hosting and integrating PMC (PCI Mezzanine Card) modules within the VME architecture.

This module serves as a bridge between the VME backplane and PMC cards, enabling seamless communication and data transfer. It allows for the easy installation and integration of multiple PMC modules, which can add a wide range of functionality such as enhanced communication interfaces, advanced data processing capabilities, or specialized control functions to the overall VME – based system. The GE VME-PMC-CADDY is built to meet the demanding requirements of industrial environments, ensuring stable operation and high – performance data handling. Its design simplifies the process of expanding and customizing VME – based control systems, making it a valuable asset for industries seeking to optimize their automation processes.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | VME-PMC-CADDY |

| Manufacturer | GE |

| Product Type | VME PMC Carrier Module |

| Form Factor | Compatible with VME and PMC standards |

| Number of PMC Slots | [Specify if known, e.g., 2] |

| Power Supply | [Provide voltage and current details if available, e.g., 5V DC, 3A] |

| Communication Interface | VME bus interface for communication with the VME backplane |

| Operating Temperature Range | – 25 °C to + 70 °C |

| Storage Temperature Range | – 40 °C to + 85 °C |

| Humidity Range | 5 – 95% (non – condensing) |

| Dimensions | [Provide specific dimensions if available, e.g., 100mm x 150mm x 30mm] |

| Weight | [Specify weight if available, e.g., 0.5 kg] |

| Mounting Type | [Describe mounting method, e.g., Rack – mountable within VME chassis] |

VME-PMC-CADDY

Main Features and Advantages

Efficient PMC Integration

The GE VME-PMC-CADDY is specifically designed to integrate PMC modules into VME – based systems with ease. It provides the necessary electrical and mechanical interfaces to securely mount and connect PMC cards. This allows users to quickly add new functionality to their VME systems by simply plugging in the appropriate PMC modules. For example, if an industrial control system requires additional communication ports, a PMC module with Ethernet or serial communication capabilities can be inserted into the VME-PMC-CADDY, expanding the system’s connectivity options.

Robust Design for Industrial Use

Built to withstand the harsh conditions of industrial environments, the VME-PMC-CADDY has a rugged construction. Its wide operating temperature range from – 25 °C to + 70 °C and tolerance to humidity levels from 5 – 95% (non – condensing) ensure reliable operation in factories, plants, and other industrial settings. The module’s components are selected for their durability, reducing the risk of failure due to environmental factors and ensuring long – term stability of the overall control system.

Flexible Expansion

With multiple PMC slots (depending on the model), the GE VME-PMC-CADDY offers great flexibility for system expansion. Users can choose from a variety of PMC modules available in the market to customize their VME – based systems according to specific application requirements. Whether it’s adding more processing power, enhancing data acquisition capabilities, or improving communication functions, the VME-PMC-CADDY enables seamless integration of these additional features, future – proofing the industrial control system.

Standardized Interface

The VME-PMC-CADDY adheres to the VME and PMC standards, ensuring compatibility with a wide range of existing VME – based equipment and PMC modules. This standardized interface simplifies the design and integration process, as engineers can rely on established protocols and specifications. It also allows for easy replacement or upgrade of components, as new PMC modules that conform to the standard can be readily integrated into the VME-PMC-CADDY without major modifications to the overall system.

VME-PMC-CADDY

Application Field

In manufacturing industries, the GE VME-PMC-CADDY is widely used in automated production lines. It can be integrated into VME – based control systems that manage the operation of robotic arms, conveyor belts, and assembly machines. For example, by inserting PMC modules with specialized control algorithms into the VME-PMC-CADDY, the system can precisely control the movement and operation of robotic arms, ensuring accurate and efficient assembly of products.

The power generation sector also benefits from the VME-PMC-CADDY. In power plants, it can be part of the control systems that monitor and regulate the operation of turbines, generators, and other power – generation equipment. PMC modules inserted into the VME-PMC-CADDY can provide enhanced data acquisition and processing capabilities, allowing for real – time monitoring of parameters such as temperature, pressure, and voltage. This enables operators to make informed decisions and optimize the power – generation process for maximum efficiency and reliability.

In the aerospace and defense industries, where high – performance and reliable control systems are crucial, the GE VME-PMC-CADDY is used in avionics systems and military control applications. It can host PMC modules with advanced communication and data processing functions, enabling secure and efficient communication between different components of the aircraft or military vehicle. The module’s ability to operate in harsh environments also makes it suitable for use in airborne and mobile military applications.

Related Products

- GE VME-PMC-CADDY – Plus: An upgraded version of the VME-PMC-CADDY, potentially offering additional features such as more PMC slots, improved power management, or enhanced communication capabilities. It can be used for more complex industrial automation projects that require greater expansion and higher performance.

- GE VME Backplane Modules: These modules are essential components of VME – based systems. They provide the electrical infrastructure for communication between different VME modules, including the VME-PMC-CADDY. Different backplane modules may have varying numbers of slots, data transfer rates, and power – delivery capabilities, and they work in tandem with the VME-PMC-CADDY to form a complete VME system.

- PMC Modules: A wide variety of PMC modules are available in the market, such as PMC – Ethernet modules for network connectivity, PMC – ADC (Analog – to – Digital Converter) modules for data acquisition, and PMC – DAC (Digital – to – Analog Converter) modules for control output. These modules can be inserted into the VME-PMC-CADDY to add specific functionality to the VME – based system, and different models offer different performance levels and features.

- VME – CPU Modules: These modules serve as the central processing units in VME – based systems. They work with the VME-PMC-CADDY and other VME modules to execute control programs and manage the overall operation of the system. Different VME – CPU modules may have different processing speeds, memory capacities, and instruction sets, and choosing the right one depends on the complexity and performance requirements of the industrial application.

- GE VME – I/O Modules: These modules provide input and output interfaces for VME – based systems. They can be used in conjunction with the VME-PMC-CADDY to connect the system to external sensors, actuators, and other devices. Examples include digital I/O modules for handling binary signals and analog I/O modules for working with continuous – range signals, and they play a crucial role in enabling the VME – based system to interact with the physical world.

Installation and Maintenance

Pre – installation preparation: Before installing the GE VME-PMC-CADDY, ensure that the power to the VME chassis is turned off to avoid electrical hazards. Familiarize yourself with the VME chassis layout and the installation instructions provided by GE. Check the compatibility of the VME-PMC-CADDY with the existing VME backplane and other modules in the system. Make sure that the PMC modules intended for installation are also compatible with the VME-PMC-CADDY and have been properly configured if necessary. When handling the VME-PMC-CADDY and PMC modules, use anti – static wrist straps or mats to prevent damage from electrostatic discharge.

Maintenance recommendations: Regularly inspect the GE VME-PMC-CADDY for any signs of physical damage, such as cracks in the casing or loose connections. Check the status of the PMC modules inserted into the VME-PMC-CADDY to ensure they are functioning properly. Monitor the operating temperature of the VME-PMC-CADDY and the overall VME system to ensure it remains within the specified range. If the system is equipped with fans for cooling, ensure that they are clean and operating correctly. Periodically clean the VME-PMC-CADDY and the VME chassis to remove dust and debris, as accumulation of these can affect the performance and reliability of the system. If any issues are detected with the VME-PMC-CADDY or the connected PMC modules, refer to the GE product documentation for troubleshooting steps or contact GE’s technical support for assistance.

Maintenance recommendations: Regularly inspect the GE VME-PMC-CADDY for any signs of physical damage, such as cracks in the casing or loose connections. Check the status of the PMC modules inserted into the VME-PMC-CADDY to ensure they are functioning properly. Monitor the operating temperature of the VME-PMC-CADDY and the overall VME system to ensure it remains within the specified range. If the system is equipped with fans for cooling, ensure that they are clean and operating correctly. Periodically clean the VME-PMC-CADDY and the VME chassis to remove dust and debris, as accumulation of these can affect the performance and reliability of the system. If any issues are detected with the VME-PMC-CADDY or the connected PMC modules, refer to the GE product documentation for troubleshooting steps or contact GE’s technical support for assistance.

Product Guarantee

GE stands firmly behind the quality of the GE VME-PMC-CADDY. The module comes with a comprehensive quality assurance guarantee. It is manufactured to strict quality standards, undergoing rigorous testing to ensure its reliability and performance. GE offers a standard warranty period for the VME-PMC-CADDY, during which, if any defects in materials or workmanship are found, GE will provide repair or replacement services free of charge. In addition to the warranty, GE provides professional technical support to assist customers with installation, configuration, and any issues that may arise during the use of the VME-PMC-CADDY. Their team of experienced engineers is available to answer questions, provide guidance, and offer solutions, ensuring that customers can make the most of the VME-PMC-CADDY in their industrial automation and control systems. This commitment to quality and customer support gives users the confidence to choose the GE VME-PMC-CADDY for their critical industrial applications.