Description

Product Overview

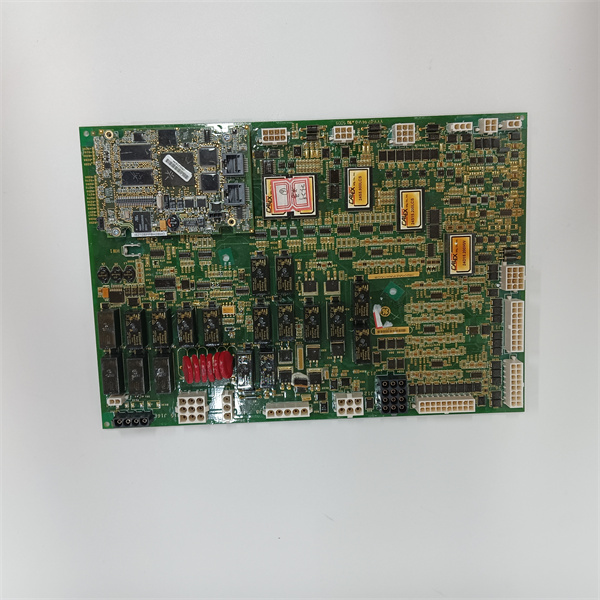

The GE UCSC H1 IS420UCSCH1A – F – VO.1 – A is a high – performance quad – core controller module, being an integral part of the GE Mark VIe series. Renowned for its advanced functionality, this module is purpose – built to meet the rigorous demands of complex industrial automation scenarios. General Electric, a global leader in industrial technology, has engineered the IS420UCSCH1A – F – VO.1 – A to offer unrivaled control and reliability.

Equipped with a 1.2 GHz quad – core processor and 4 GB of DDR3 SDRAM memory, it can execute tasks at high speeds, ensuring rapid response times in real – time control applications. It runs on the QNX Neutrino operating system, which is celebrated for its stability and real – time performance, even in the most challenging industrial conditions. This controller module doesn’t host any application I/O, yet it plays a pivotal role in integrating with other components within the Mark VIe system. It enables seamless communication and data transfer, thereby enhancing the overall efficiency and accuracy of the industrial control system. Whether it’s in a large – scale power generation plant or a high – precision manufacturing facility, the GE UCSC H1 IS420UCSCH1A – F – VO.1 – A is designed to optimize operations and drive productivity.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS420UCSCH1A – F – VO.1 – A |

| Manufacturer | GE |

| Product Type | Controller Module |

| Processor | 1.2 GHz quad – core |

| Memory | 4 GB DDR3 SDRAM |

| Operating System | QNX Neutrino |

| Input/Output | Two Hall effect pulse inputs, two analog inputs, four digital I/Os |

| Redundancy | Supports TMR (Triple Modular Redundancy), simplex, and dual redundancy |

| Operating Voltage | 220 V |

| Frequency Output | 50 kHz |

| Communication Interfaces | Ethernet, USB, CAN bus |

| Operating Temperature Range | – 40 °C to + 85 °C |

| Dimensions | 140 mm x 100 mm x 40 mm |

Main Features and Advantages

High – Performance Processing

The GE UCSC H1 IS420UCSCH1A – F – VO.1 – A‘s 1.2 GHz quad – core processor allows for lightning – fast data processing. In industrial applications where split – second decisions are crucial, such as in high – speed manufacturing lines or power grid control, it can quickly analyze incoming data from sensors and execute control commands. This high – speed processing not only improves the efficiency of the industrial process but also reduces the likelihood of errors due to delays in data handling.

Reliable Operating System

Running on the QNX Neutrino operating system, the module offers unparalleled stability. QNX Neutrino is designed to operate in harsh industrial environments, with a high degree of resistance to crashes and system failures. In power generation plants, where continuous operation is essential, the IS420UCSCH1A – F – VO.1 – A can maintain stable control over turbines and generators, ensuring uninterrupted power supply. The operating system also enables real – time multitasking, allowing the controller to handle multiple control tasks simultaneously without performance degradation.

Versatile Redundancy Options

With support for TMR, simplex, and dual redundancy, the GE UCSC H1 IS420UCSCH1A – F – VO.1 – A is highly fault – tolerant. In critical applications like oil and gas production, where any system downtime can lead to significant financial losses and safety risks, the redundancy features ensure continuous operation. For example, in a TMR configuration, the controller has three independent processing channels that constantly cross – check each other’s results. If one channel fails, the system can continue operating using the data from the remaining two channels, providing a high level of reliability and availability.

Application Field

Power Generation

In power plants, the GE UCSC H1 IS420UCSCH1A – F – VO.1 – A is used to control steam and gas turbines. It precisely regulates the speed and load of the turbines, optimizing power generation efficiency. In a combined – cycle power plant, it coordinates the operation of the gas turbine, steam turbine, and heat recovery steam generator, ensuring seamless integration of different power – generating components. It also monitors and controls parameters such as temperature, pressure, and fuel flow, safeguarding the safe and efficient operation of the entire power generation system.

Oil and Gas

The oil and gas industry relies on the IS420UCSCH1A – F – VO.1 – A for various applications. In oil refineries, it controls the complex processes of distillation, cracking, and reforming. It monitors the flow of crude oil, intermediate products, and refined products through pipelines, valves, and storage tanks. In offshore oil platforms, the controller manages the operation of drilling equipment, pumps, and compressors. Its high – reliability features are especially crucial in these remote and harsh environments, where maintenance and repairs can be challenging and costly.

Manufacturing

In manufacturing facilities, the GE UCSC H1 IS420UCSCH1A – F – VO.1 – A is used to control automated production lines. It coordinates the movement of robotic arms, conveyor belts, and other manufacturing equipment. In an automotive manufacturing plant, for instance, it ensures the precise assembly of car parts by controlling the position and movement of robotic arms. It also monitors the quality of products in real – time, using data from sensors to detect any defects and adjust the production process accordingly, thus improving product quality and production efficiency.

Related Products

- GE IS420UCSBH1A: A UCSB controller module within the GE product family. Unlike the IS420UCSCH1A – F – VO.1 – A, the UCSBH1A has its own unique set of features. It is designed to execute specific application – control system logic but does not host application I/O. It may be used in scenarios where a different set of control functions or a more basic level of processing power is required compared to the quad – core IS420UCSCH1A – F – VO.1 – A.

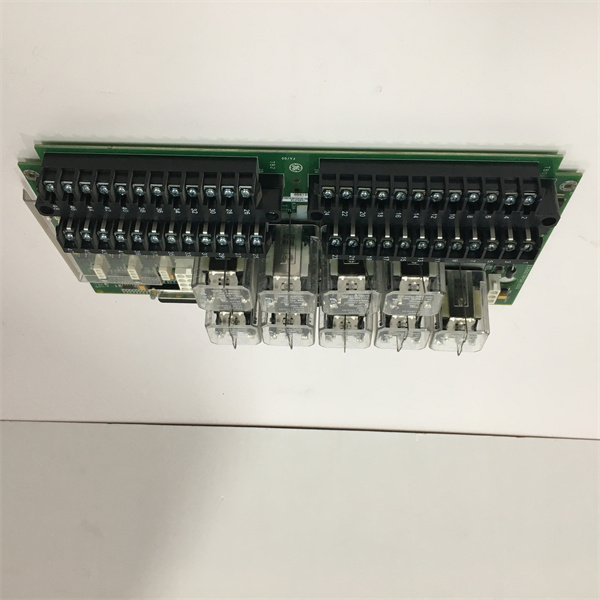

- GE IS420UCSDH1A: A digital discrete output module. While the IS420UCSCH1A – F – VO.1 – A is a controller module that processes and manages overall control logic, the UCSDH1A is responsible for providing digital discrete output signals. It can be used in conjunction with the IS420UCSCH1A – F – VO.1 – A in industrial control systems where the controller needs to send out digital signals to control external devices such as relays, contactors, or indicator lamps.

- GE Mark VIe Series Controllers (other models): There are other controllers in the Mark VIe series. Some may have different levels of processing power, different types of I/O configurations, or be optimized for specific sub – industries. For example, certain models might be more tailored towards small – scale industrial applications, while the IS420UCSCH1A – F – VO.1 – A is designed for more demanding, large – scale operations.

- GE E33NRHA – LNN – NS – 00: Although details are scarce, it could potentially be a related control or drive module. It may operate in a different voltage range, have different communication protocols, or be designed for a different subset of industrial applications compared to the IS420UCSCH1A – F – VO.1 – A. However, both are likely to be part of GE’s broad portfolio of industrial automation products.

- GE IC693CHS398: A 5 – slot expansion baseplate for the GE Series 90 – 30 programmable logic controller (PLC) platform. While it is not directly a controller like the IS420UCSCH1A – F – VO.1 – A, it can be used in an industrial control setup where additional I/O or option modules need to be integrated. The IS420UCSCH1A – F – VO.1 – A could potentially communicate with a system that has an IC693CHS398 baseplate to expand the overall control system’s capabilities.

Installation and Maintenance

Pre – installation preparation: Before installing the GE UCSC H1 IS420UCSCH1A – F – VO.1 – A, ensure that the power to the entire industrial control system is switched off to avoid electrical hazards. Thoroughly read the installation manual provided by GE, which details the proper mounting procedures. The UCSC device should be directly installed onto the designated installation 基座. Make sure to leave at least 4 inches of air gap above and below the UCSC to facilitate proper ventilation and heat dissipation. Also, verify that the surrounding environment meets the specified operating temperature range of – 40 °C to + 85 °C.

Maintenance recommendations: Regularly inspect the IS420UCSCH1A – F – VO.1 – A for any visible signs of damage, such as discolored components or loose connections. Clean the module periodically to remove dust and debris, as these can affect the performance and heat dissipation. Monitor the operating temperature of the module during normal operation; if it exceeds the recommended range, investigate the cause, which could be due to a cooling system issue or excessive load. Check the status of the LEDs on the module, as they can provide valuable information about the operational status and potential faults. If any malfunctions are detected, refer to the troubleshooting section of the product manual or contact GE’s technical support for further assistance.

Maintenance recommendations: Regularly inspect the IS420UCSCH1A – F – VO.1 – A for any visible signs of damage, such as discolored components or loose connections. Clean the module periodically to remove dust and debris, as these can affect the performance and heat dissipation. Monitor the operating temperature of the module during normal operation; if it exceeds the recommended range, investigate the cause, which could be due to a cooling system issue or excessive load. Check the status of the LEDs on the module, as they can provide valuable information about the operational status and potential faults. If any malfunctions are detected, refer to the troubleshooting section of the product manual or contact GE’s technical support for further assistance.

Product Guarantee

GE stands firmly behind the quality of the GE UCSC H1 IS420UCSCH1A – F – VO.1 – A. The module undergoes strict quality control during the manufacturing process to meet high – performance standards. GE typically offers a comprehensive warranty, often spanning a specific period, which covers manufacturing defects. In case of any quality – related issues within the warranty period, GE’s global technical support team is readily available. They can provide detailed guidance on installation, troubleshooting, and, if necessary, arrange for the repair or replacement of the IS420UCSCH1A – F – VO.1 – A module. This demonstrates GE’s commitment to customer satisfaction and the long – term reliability of their product in industrial applications, giving users confidence in the module’s performance over its lifespan.