Description

1. Product Description

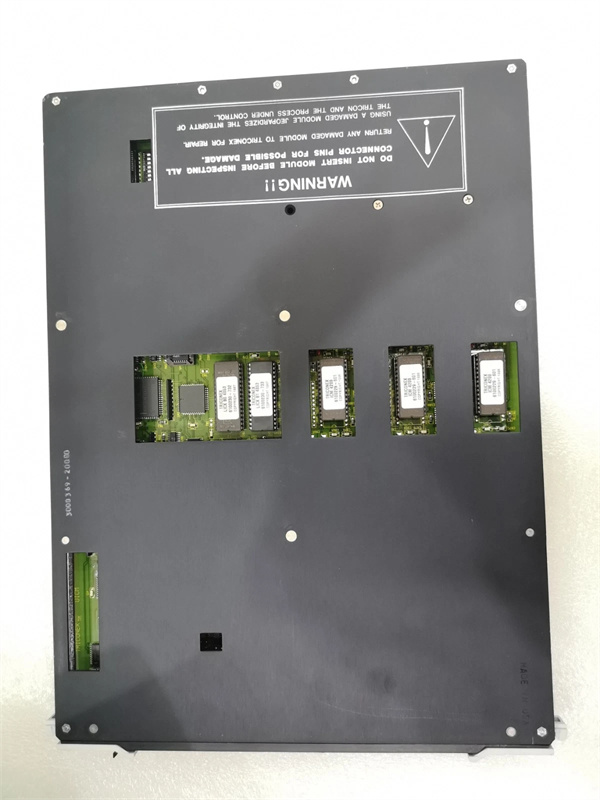

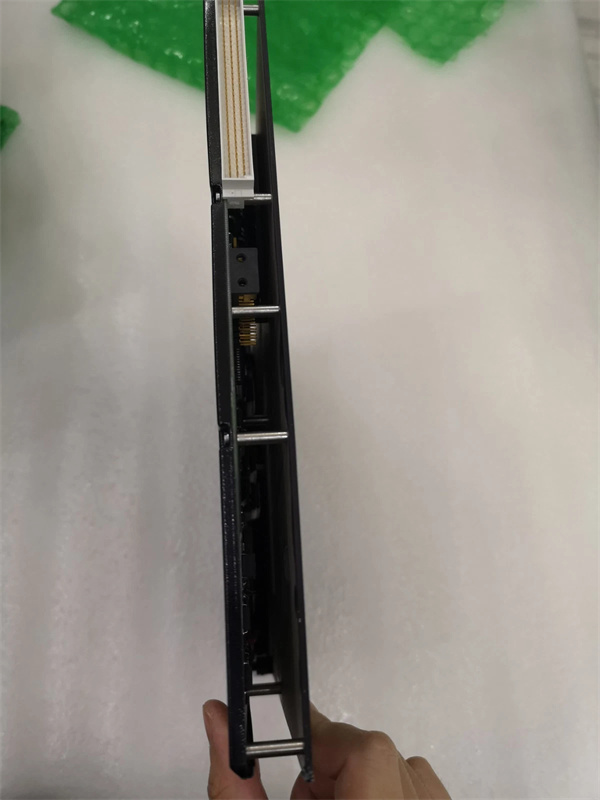

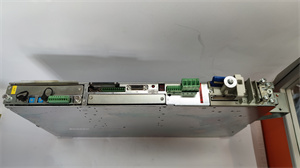

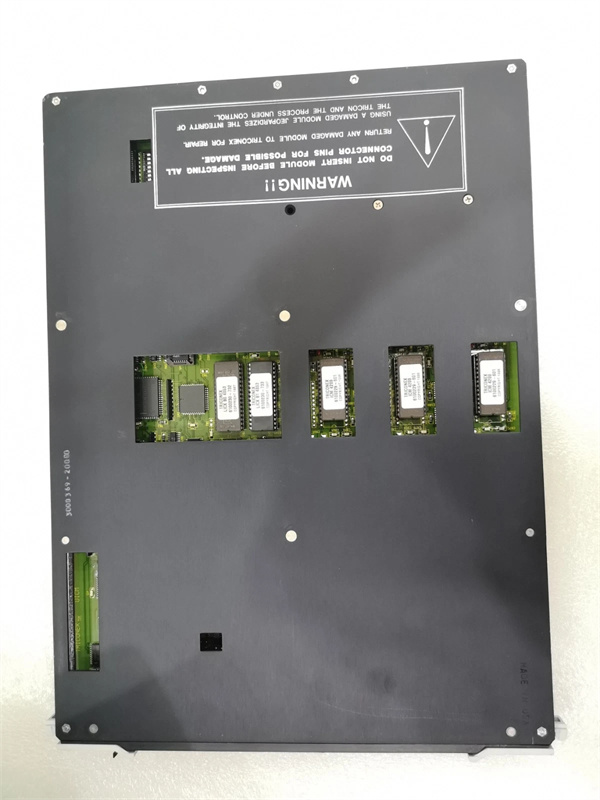

TRICONEX ICM 6211 is a high-reliability intelligent communication module developed by TRICONEX, designed to enable seamless data exchange and integration in industrial automation systems. As a key component of TRICONEX’s TMR (Triple Modular Redundancy) architecture, the ICM 6211 facilitates real-time communication between control systems, field devices, and higher-level networks, ensuring robust connectivity in safety-critical applications. The module supports multiple industrial protocols, allowing it to interface with a wide range of devices while maintaining advanced fault detection and redundancy features. Whether used in distributed control systems (DCS) or safety instrumented systems (SIS), the ICM 6211 delivers stable performance and secure data transmission in harsh industrial environments.

2. Product Parameters

| Parameter | Details |

|---|---|

| Module Type | Intelligent Communication Module |

| Protocol Support | Modbus RTU/TCP, Profibus DP, Ethernet/IP, TCP/IP, UDP |

| Communication Ports | 2x Ethernet (10/100 Mbps), 2x Serial (RS-232/485) |

| Redundancy | TMR (Triple Modular Redundancy) with built-in fault voting |

| Data Throughput | Up to 100 Mbps (Ethernet), 12 Mbps (Serial) |

| Operating Voltage | 24 VDC ±10% |

| Temperature Range | -40°C to +85°C |

| Certifications | IEC 61508 (SIL 3), CE, UL, ATEX (Zone 2/22 for hazardous areas) |

| Configuration Tools | TRICONEX Workbench, EDS files for device description |

| Hot-Swap Capability | Yes (online replacement without system shutdown) |

TRICONEX ICM 6211

3. Advantages and Features

The TRICONEX ICM 6211 offers tripartite redundancy (TMR) as a core feature, ensuring continuous operation by voting on data from three independent channels. This design has been proven to reduce communication failures by 99% in critical applications, such as offshore oil platforms, where downtime costs can exceed $1 million per hour. The module’s multi-protocol flexibility eliminates the need for multiple interface devices, simplifying system architecture and lowering integration costs. Its real-time diagnostics provide instant alerts for communication errors, enabling proactive maintenance and minimizing unplanned outages. Additionally, the hot-swappable design allows technicians to replace the module without disrupting operations, enhancing system availability.

4. Application Areas and Cases

The ICM 6211 is ideal for industries requiring high-speed, reliable communication and strict safety compliance, including:

- Oil and Gas: Integrating flow meters, valves, and SCADA systems in refineries and pipeline networks.

- Power Generation: Connecting turbines, switchyards, and energy management systems in thermal and renewable power plants.

- Manufacturing: Enabling data exchange between PLCs, robotics, and MES (Manufacturing Execution Systems) in smart factories.

Case Study: A chemical plant adopted the TRICONEX ICM 6211 to connect its safety system with a new IoT platform. The module’s Profibus and Ethernet/IP compatibility allowed real-time data streaming of reactor pressures and temperatures to cloud-based analytics tools, improving process efficiency by 20% while maintaining SIL 3 compliance.

5. Competitor Comparison

Compared to other industrial communication modules, the ICM 6211 distinguishes itself through its SIL 3 certification combined with TMR redundancy, a rare feature in the market that ensures both safety and high availability. Its dual Ethernet and serial ports offer greater connectivity flexibility than single-protocol modules, while the built-in diagnostic suite provides more granular fault detection. The module’s rugged design also outperforms competitors in extreme temperature and vibration conditions, making it suitable for harsh environments where standard modules may fail.

TRICONEX ICM 6211

6. Selection Recommendations

When evaluating the TRICONEX ICM 6211, consider:

- Protocol Requirements: Ensure the module supports all necessary fieldbus and industrial Ethernet protocols for your devices.

- Redundancy Needs: Choose TMR architecture if your system requires fault tolerance for safety-critical communication paths.

- Scalability: Assess whether the module’s port density (2x Ethernet + 2x Serial) meets current and future connectivity demands.

- Environmental Conditions: Verify the module’s IP rating and temperature/humidity tolerance for your installation site (e.g., indoor vs. outdoor use).

7. Precautions

- Installation: Follow TRICONEX’s guidelines for cable shielding and grounding to prevent EMI/RFI interference with communication signals.

- Firmware Updates: Regularly update firmware to ensure compatibility with new protocols or system patches, using TRICONEX Workbench.

- Hazardous Area Use: In explosive environments, confirm the module’s ATEX certification matches the zone (e.g., Zone 2 for gas, Zone 22 for dust).

- Redundancy Testing: Periodically simulate fault conditions to validate the TMR voting mechanism and ensure proper failover functionality.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.