Description

Product Overview

The GE PV2121ED160012CT is a communication module designed to meet the demands of industrial and power – related applications, proudly brought to you by General Electric. In the complex landscape of industrial automation and power system management, this module plays a crucial role in facilitating seamless data transfer and communication.

It is engineered to be a reliable data – handling component. With its specific configuration capabilities, it can manage different types of reporting mechanisms. For instance, in the case of buffered reports, it allows only one client to enable the relevant reporting attribute at a time, ensuring exclusive access to the associated buffer until the connection is closed or the attribute is disabled. On the other hand, for unbuffered reports, up to six clients can simultaneously enable the reporting attribute, each having independent access to a copy of the relevant data structure. This flexibility in handling reporting makes it suitable for various industrial setups where data distribution and access control are vital. Whether it’s in a power plant monitoring critical equipment status or an industrial manufacturing facility coordinating production processes, the GE PV2121ED160012CT communication module provides the necessary means to keep the data flow organized and efficient.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | PV2121ED160012CT |

| Manufacturer | General Electric |

| Product Type | Communication Module |

| Reporting Frequency | 2 Hz for service |

| Buffered Report Access | Only one client can enable RptEna of BRCB at a time; associated client has exclusive access until connection closed or RptEna disabled |

| Unbuffered Report Access | Up to six clients can enable RptEna of URCB at a time; each client has independent access to a copy of URCB |

| IntgPd Resolution | 1 ms (client – settable, but integrity report sent when period expires, with report sent within 500 ms of IntgPd expiration) |

| Resv Attribute | Writable, but SEL – 710 does not support reservations; writing URCB fields gives client its own URCB copy |

| Origin | USA |

| Warranty | Seven – day acceptance period, one – year warranty period |

| Delivery Time | 1 – 3 working days |

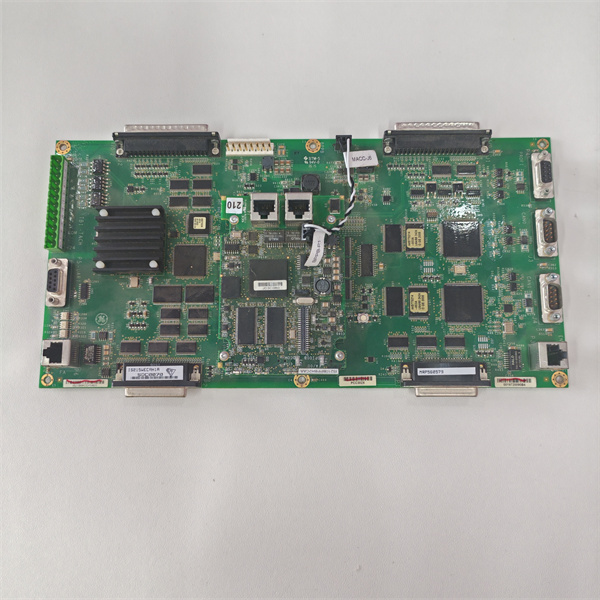

IS210MACCH1AKH

Main Features and Advantages

Flexible Reporting Mechanisms

The GE PV2121ED160012CT offers distinct ways to handle reports. The buffered report system, with its single – client – enabled access, is beneficial in scenarios where data integrity and exclusive access are crucial. For example, in a power grid control center, when a particular operation requires real – time and uninterrupted access to specific data, the buffered report feature ensures that only the authorized client can access and act on that data. In contrast, the unbuffered report system, allowing multiple clients to access data simultaneously, is ideal for situations like large – scale industrial monitoring where different departments or systems need to access the same set of data for their respective operations, such as quality control and production planning in a manufacturing plant.

High – Frequency Reporting

With a 2 Hz reporting service rate, the module can quickly transmit data. In applications where real – time information is essential, like in a fast – paced manufacturing process where any delay in data transmission can lead to production inefficiencies or in a power plant where immediate response to equipment status changes is required, the PV2121ED160012CT ensures that the latest data is available promptly. This high – frequency reporting helps in making timely decisions and maintaining the smooth operation of the overall system.

Precise Time – related Settings

The ability to set the IntgPd (Integrity Period) with a resolution of 1 ms gives users fine – grained control over when integrity reports are sent. This is extremely useful in systems where precise timing of data updates is critical. For instance, in a highly synchronized industrial process where different machines need to operate based on the exact status of other components, the accurate setting of IntgPd ensures that the data used for coordination is up – to – date and relevant, minimizing the risk of miscommunication and potential production errors.

Application Field

In power generation plants, the GE PV2121ED160012CT is extensively used for monitoring and controlling various aspects of the power – generation process. It can be used to communicate data from sensors placed on generators, transformers, and other critical equipment. For example, it can relay information about the temperature, vibration, and electrical parameters of these components to the central control system. This enables operators to monitor the health of the equipment in real – time and take preventive measures in case of any anomalies, ensuring the stable and efficient operation of the power plant.

Industrial manufacturing facilities also rely on this module. In a large – scale automotive manufacturing plant, for instance, the PV2121ED160012CT can be used to transfer data between different production lines, robots, and control systems. It helps in coordinating the movement of parts, controlling the speed of conveyor belts, and ensuring that the overall manufacturing process is synchronized. By facilitating seamless communication, it contributes to improving production efficiency, reducing downtime, and enhancing product quality.

In smart grid applications, the module plays a role in enabling communication between different grid components. It can transfer data related to power consumption, voltage levels, and load distribution. This information is used by grid operators to optimize power flow, manage peak loads, and ensure the reliability of the power supply. The GE PV2121ED160012CT thus helps in making the smart grid more intelligent and responsive to the changing demands of electricity users.

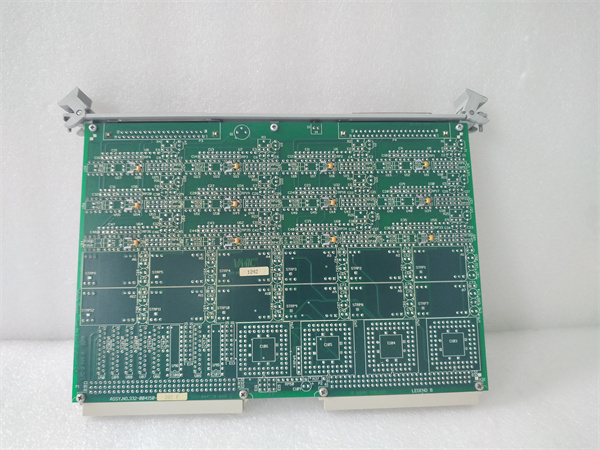

IC697MDL653

Related Products

- GE IC693PWR330G: This is a power supply module from GE. While the PV2121ED160012CT focuses on communication functions, the IC693PWR330G provides the necessary electrical power for the overall system. They often work together in industrial setups where a stable power supply is required to support the communication operations of the PV2121ED160012CT and other components in the system.

- GE VME – MB – Z004: A module that may be part of the same VME – based system as the PV2121ED160012CT. It could have different functions, such as providing additional I/O capabilities or acting as a bridge between different subsystems. In an industrial control system using VME architecture, these two modules might interact to enable a more comprehensive control and monitoring solution.

- GE SEL – 710: Although not directly a communication module like the PV2121ED160012CT, it is related in terms of data handling. The SEL – 710 has its own data – related features, and the PV2121ED160012CT may interact with it in certain industrial applications. For example, the PV2121ED160012CT might transfer data to the SEL – 710 for further processing or analysis in a power system protection and control setup.

- GE other communication modules: There are other communication modules in GE’s product line. Some may have different communication protocols, bandwidth capabilities, or be designed for specific industries or applications. For example, there could be modules optimized for wireless communication in remote industrial sites, while the PV2121ED160012CT is more focused on wired communication within a local industrial network.

- GE industrial control modules: These modules are used for controlling industrial processes. The PV2121ED160012CT can supply the control modules with relevant data, such as sensor readings or status information, enabling them to make informed control decisions. In a manufacturing process, the control modules can use the data from the PV2121ED160012CT to adjust the operation of machinery and ensure the smooth running of the production line.

Installation and Maintenance

Pre – installation preparation: Before installing the GE PV2121ED160012CT, ensure that the power to the system it will be integrated into is turned off to avoid electrical hazards. Thoroughly inspect the module for any visible signs of damage during transportation. Familiarize yourself with the overall system architecture and the communication protocols it uses. Check the compatibility of the PV2121ED160012CT with other components in the system, especially in terms of electrical interfaces and data – handling capabilities. Prepare the necessary tools for physical installation, such as screwdrivers if it needs to be mounted in a chassis. Also, make sure the installation environment meets the module’s requirements in terms of temperature, humidity, and electromagnetic interference.

Maintenance recommendations: Regularly monitor the PV2121ED160012CT for any signs of abnormal operation. Check the data transmission status to ensure that reports are being sent and received correctly at the expected frequencies. If there are any issues with data communication, first check the connections, both physical and logical. Clean the module periodically to remove dust and debris, as these can affect its performance over time. In case of hardware failures, refer to the manufacturer’s documentation for troubleshooting steps. If a particular reporting function fails, check the relevant settings and configurations. Keep the module’s firmware updated if available, as this can improve performance, fix bugs, and enhance compatibility with other system components.

Product Guarantee

GE stands firmly behind the quality of the GE PV2121ED160012CT. During the manufacturing process, strict quality – control measures are implemented to ensure that each module meets high – industry standards. The product comes with a seven – day acceptance period and a one – year warranty. In the event of any manufacturing defects within the warranty period, GE offers comprehensive after – sales service. This includes free repair or replacement of the module, along with technical support from its team of experts. GE’s global network of support centers is available to assist customers promptly. Whether it’s installation – related queries, troubleshooting communication issues, or advice on system integration, customers can rely on GE’s expertise. This commitment not only reflects GE’s confidence in the reliability and performance of the PV2121ED160012CT but also provides industrial customers with the assurance they need to operate their systems with peace of mind.