Description

Product Overview

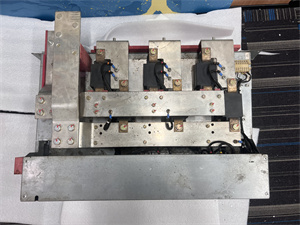

The GE MVR1600 – 4601 is a remarkable fast delta rectifier, a solid – state device that plays a pivotal role in power conversion within industrial settings. It is designed to efficiently convert alternating current (AC) into direct current (DC), serving as a fundamental building block for numerous industrial power systems.

As part of GE’s product portfolio, the MVR1600 – 4601 is engineered to meet the rigorous demands of industrial applications. With a continuous DC current output of 1600 amps, it can handle substantial power loads. The module is suitable for input voltages ranging from 380 to 500 Vac, providing flexibility in different electrical environments. It then outputs a DC voltage within the range of 130 to 375 vdc, which is compatible with a wide array of downstream equipment. This rectifier module is particularly well – suited for powering DC motors, drives, and other industrial equipment, ensuring stable and reliable operation.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | MVR1600 – 4601 |

| Manufacturer | General Electric (GE) |

| Product Type | Fast Delta Rectifier |

| Continuous DC Current Output | 1600 amps |

| Input Voltage Range | 380 – 500 Vac |

| Output Voltage Range | 130 – 375 vdc |

| Cooling Method | Air – cooled |

| Weight | Approximately 2 kg (varies based on source) |

| Dimensions | Specifics not fully consistent across sources, but generally compact for industrial use |

| Package Type | Carton |

| Certification | CE, UL (as per some sources indicating compliance with international safety standards) |

MVR1600-4601

Main Features and Advantages

High – Capacity Current Output

The GE MVR1600 – 4601 offers an impressive continuous DC current output of 1600 amps. This high – capacity output makes it ideal for power – hungry industrial equipment, ensuring that machinery can operate at full capacity without power – related bottlenecks. Whether it’s driving large – scale DC motors in manufacturing plants or powering industrial drives, the module can handle the load with ease.

Wide Input Voltage Range

With an input voltage range spanning from 380 to 500 Vac, the rectifier module can be used in various industrial locations with different power supply standards. This versatility eliminates the need for complex and costly voltage conversion systems in many cases. It can adapt to the electrical infrastructure of different factories, power plants, or other industrial facilities, enhancing its applicability across a wide range of industries.

Compact and Lightweight Design

Despite its powerful performance capabilities, the MVR1600 – 4601 features a compact and lightweight design. This makes it easy to install in areas with limited space, such as within electrical cabinets or on machinery where space is at a premium. The reduced weight also simplifies handling during installation and maintenance, reducing the risk of injury and making the process more efficient.

Air – Cooled Design

The air – cooled design of the module is a significant advantage. It allows for natural heat dissipation, eliminating the need for additional complex cooling systems like liquid – cooling setups. This not only reduces the overall cost of the system but also enhances its reliability, as there are fewer components that can potentially fail. The air – cooled design is also more environmentally friendly, as it does not require the use of cooling fluids.

Application Field

Chemical Processing

In chemical processing plants, the GE MVR1600 – 4601 is used to power DC – driven equipment such as pumps, agitators, and compressors. These devices are crucial for processes like mixing chemicals, transporting fluids, and maintaining pressure within reaction vessels. The stable DC power provided by the rectifier module ensures the precise operation of these machines, which is essential for consistent chemical production and quality control.

Oil and Gas Refining

Within the oil and gas refining industry, the rectifier module plays a vital role. It powers DC motors that drive pumps used to transfer crude oil, refined products, and various process fluids. In addition, it can be used to supply power to control systems and instrumentation in refineries. The ability of the MVR1600 – 4601 to handle high – power loads and its wide input voltage range make it suitable for the demanding electrical requirements of oil and gas refining facilities.

Power Generation

In power generation plants, whether they are based on fossil fuels, renewables like wind or solar, or other sources, the MVR1600 – 4601 can be used in multiple ways. For example, it can convert AC power from generators into DC power for battery charging systems, which are used for backup power in case of emergencies. It can also power DC – operated equipment within the plant, such as certain types of fans, valves, and control devices, contributing to the overall stable operation of the power generation process.

Water and Wastewater Treatment

Water and wastewater treatment plants rely on a variety of DC – powered equipment, and the GE MVR1600 – 4601 can meet their power needs. It can supply power to DC motors that drive pumps for water circulation, filtration systems, and sludge handling equipment. The stable DC power helps in maintaining the proper flow and treatment processes, ensuring the production of clean water and the effective treatment of wastewater.

MVR1600-4601

Related Products

- GE MVR1600 – [Other Variants]: These are likely to be similar rectifier modules within the MVR1600 series. They may have different current or voltage ratings, or additional features such as enhanced cooling mechanisms or more precise voltage regulation, catering to specific industrial applications with different power requirements.

- GE MVRL2100/4601: This is a liquid – cooled rectifier module from GE. While the MVR1600 – 4601 is air – cooled, the MVRL2100/4601 uses liquid cooling, which may be more suitable for applications where higher heat dissipation is required, such as in high – power density systems. It also has a different maximum DC output voltage and may have unique design features for specific industrial uses.

- GE – Branded AC – DC Converters (Other Models): There are other AC – DC converter models from GE. Some may be designed for lower – power applications, while others may offer different conversion efficiencies or have additional built – in protection features. These can be alternatives or complementary products depending on the scale and requirements of the industrial power conversion task.

- GE Power Supplies with Different Outputs: These power supplies may have different voltage and current output characteristics compared to the MVR1600 – 4601. They could be used in parallel with the rectifier module in some cases to meet the diverse power needs of complex industrial systems, or as standalone power sources for equipment with different power requirements.

- GE Control Modules for Power Systems: These control modules can work in tandem with the MVR1600 – 4601 to regulate and manage the power output. They can monitor the rectifier’s performance, adjust voltage and current levels as needed, and ensure the safe and efficient operation of the overall power system in which the rectifier is integrated.

Installation and Maintenance

Pre – installation preparation: Before installing the GE MVR1600 – 4601, it is crucial to turn off the power supply to the entire system to avoid electrical accidents. Carefully check the compatibility of the module with the existing electrical infrastructure, ensuring that the input voltage range of the module matches the available AC power supply. Inspect the module for any visible signs of damage during transit, such as cracks or loose components. Follow the installation manual provided by GE meticulously, which will guide you on proper mounting techniques, wiring connections, and grounding procedures. Use appropriate tools and ensure that all connections are secure to prevent electrical arcing or power loss.

Maintenance recommendations: Regularly monitor the performance of the MVR1600 – 4601 by checking the input and output voltages and currents using calibrated measuring equipment. Ensure that they are within the specified ranges as per the product specifications. Inspect the module for any signs of overheating, such as discolored components or an abnormal smell. Clean the module periodically to remove dust and debris, especially from the air – cooling fins, as these can impede heat dissipation. Check the wiring connections for any signs of looseness or corrosion. If any issues are detected, refer to the troubleshooting section of the manual or contact GE’s technical support for assistance. Replace any worn – out or damaged parts promptly with genuine GE components to maintain the integrity and performance of the rectifier module.

Maintenance recommendations: Regularly monitor the performance of the MVR1600 – 4601 by checking the input and output voltages and currents using calibrated measuring equipment. Ensure that they are within the specified ranges as per the product specifications. Inspect the module for any signs of overheating, such as discolored components or an abnormal smell. Clean the module periodically to remove dust and debris, especially from the air – cooling fins, as these can impede heat dissipation. Check the wiring connections for any signs of looseness or corrosion. If any issues are detected, refer to the troubleshooting section of the manual or contact GE’s technical support for assistance. Replace any worn – out or damaged parts promptly with genuine GE components to maintain the integrity and performance of the rectifier module.

Product Guarantee

GE stands firmly behind the quality of the GE MVR1600 – 4601 rectifier module. The product typically comes with a comprehensive warranty, the duration of which is clearly specified in the product documentation. During this warranty period, if there are any manufacturing defects, GE will, at its discretion, repair or replace the module free of charge. GE’s global network of technical support teams is available to assist customers around the clock. Whether it’s providing guidance during installation, helping with troubleshooting operational problems, or offering advice on maintenance, GE’s experts are committed to ensuring the optimal performance of the MVR1600 – 4601. With strict quality control measures implemented throughout the production process, GE demonstrates its confidence in the reliability of this module, reflecting its long – standing dedication to customer satisfaction in the industrial automation and power system markets.