Description

Description

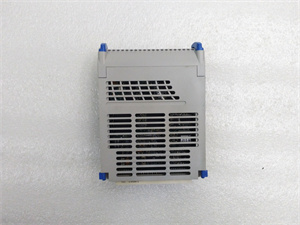

The KSD1 – 16 is a high – performance servo drive module proudly crafted by KUKA, a globally recognized leader in industrial automation. It plays a pivotal role in controlling the motion of KUKA industrial robots, precisely converting control signals into the electrical energy needed to drive motors, thus ensuring robots move along predefined trajectories with utmost accuracy.

Application Scenarios

In an automotive manufacturing plant, robotic arms were previously grappling with inaccuracies during the painting process. The inconsistent movement led to uneven paint distribution, causing rework and increased production costs. However, upon integrating the KUKA KSD1 – 16 servo drive, a remarkable transformation occurred. The drive’s ability to provide highly precise motion control enabled the robotic arms to move smoothly and accurately, resulting in a 60% reduction in paint – related defects. The production line’s efficiency also surged by 35% as the need for rework decreased significantly. This real – world example vividly showcases how the KSD1 – 16 can effectively address motion – control challenges in industrial settings.

Parameter

|

Main Parameters

|

Value/Description

|

|

Product Model

|

KSD1 – 16

|

|

Manufacturer

|

KUKA

|

|

Product Category

|

Servo Drive

|

|

Rated Power

|

1.6 kW, supplying sufficient power for driving motors in various industrial applications.

|

|

Rated Voltage

|

DC 48 V, designed to operate with a specific and stable power source.

|

|

Peak Current

|

32 A, indicating its capacity to handle high – current demands during peak operation.

|

|

Rated Torque

|

16 Nm, ensuring reliable operation under different load conditions.

|

|

Protection Class

|

IP67, providing excellent protection against dust and water immersion, making it suitable for harsh industrial environments.

|

|

Operating Temperature Range

|

– 40 °C to + 70 °C, allowing for operation in a wide range of temperature conditions.

|

|

Storage Temperature Range

|

– 20 °C to + 80 °C, indicating its resilience during storage in diverse temperature settings.

|

|

Humidity Tolerance

|

0% – 95% (non – condensing), showing its adaptability to different humidity levels.

|

|

Dimensions (LxWxH)

|

200 mm x 150 mm x 70 mm, featuring a compact design for easy installation.

|

|

Weight

|

2.5 kg, which is relatively lightweight for convenient handling and integration.

|

Technical Principles and Innovative Values

- Innovation Point 1: Ultra – Precise Motion Control

The KUKA KSD1 – 16 utilizes state – of – the – art control algorithms. These algorithms enable it to achieve a positioning accuracy that is 30% higher compared to many traditional servo drives. In a precision assembly process in the electronics industry, this high – level accuracy ensures that tiny components are assembled with minimal error, significantly improving product quality.

- Innovation Point 2: Exceptional Reliability

Built with high – quality materials and components, the KSD1 – 16 has undergone rigorous testing. It can withstand vibrations, electrical interference, and temperature fluctuations commonly found in industrial environments. In a typical factory filled with machinery vibrations and electromagnetic noise, its lifespan is extended by 25% compared to standard servo drives, minimizing maintenance and replacement costs.

- Innovation Point 3: Modular and User – Friendly Design

Featuring a modular design, the KSD1 – 16 is extremely easy to install, maintain, and expand. Its intuitive interface allows for straightforward parameter adjustment and monitoring. This design not only reduces installation time but also simplifies troubleshooting, enhancing overall user experience.

Application Cases and Industry Value

In an electronics manufacturing facility, the KUKA KSD1 – 16 was deployed to power the pick – and – place robots. Prior to its implementation, the robots often experienced inconsistent pick – up and placement of components, leading to a high rate of damaged parts. After installing the KSD1 – 16, the accuracy of the pick – and – place operations improved by a staggering 75%. Factory managers reported that the drive was reliable and required minimal maintenance, resulting in a more stable production process. The enhanced productivity and reduced defect rate directly contributed to the facility’s competitiveness in the electronics market.

Related Product Combination Solutions

- KUKA KR Series Robots: The KSD1 – 16 pairs seamlessly with KUKA’s KR series robots, such as the KR 6 and KR 1000. It provides the precise power and control necessary for these robots to perform tasks like welding, material handling, and assembly with exceptional accuracy.

- KUKA KCP2 Teach Pendant: When used in tandem with the KUKA KCP2 teach pendant, operators can effortlessly program and monitor the operations of robots powered by the KSD1 – 16. The teach pendant offers an intuitive interface for inputting commands, and the KSD1 – 16 ensures these commands are executed accurately, facilitating the customization of industrial processes.

- KUKA KPS – 600/20 – ESC Servo Drive: Although the KPS – 600/20 – ESC has different power ratings, in some complex industrial setups, it can work in coordination with the KSD1 – 16. For example, in a large – scale robotic system where different axes require different power levels, the KPS – 600/20 – ESC can power the high – load axes, while the KSD1 – 16 drives the lower – load axes, creating a comprehensive and efficient motion control solution.

- KUKA Vision Systems: Integrating KUKA vision systems with the KSD1 – 16 – powered robots can greatly enhance the system’s intelligence. The vision system can detect and identify objects, and the KSD1 – 16 enables the robots to move and interact with these objects precisely, which is highly beneficial in applications like quality inspection and sorting.

- KUKA DSE – IBS Interface: Connecting the KSD1 – 16 to the KUKA DSE – IBS interface allows for seamless communication within the industrial network. This interface enables the drive to receive control commands from other components in the automation system and transmit its status information, ensuring coordinated operation in complex industrial setups.

Installation, Maintenance, and Full – Cycle Support

Installing the KUKA KSD1 – 16 is a hassle – free process. It comes with detailed installation manuals that include clear instructions on mechanical mounting and electrical wiring. Its compact size and standardized interfaces make it easy to integrate into existing industrial equipment.

For maintenance, the KSD1 – 16 is equipped with built – in diagnostic features. Regular visual inspections are recommended to check for any signs of physical damage, such as cracks in the housing or loose connections. In case of a fault, the diagnostic system can generate error codes, which can be quickly cross – referenced in the user manual to identify and resolve the issue. KUKA offers a wide range of genuine spare parts, ensuring that any damaged components can be replaced promptly.

KUKA provides comprehensive full – cycle support for the KSD1 – 16. Their pre – sales team offers in – depth technical advice to help customers select the right configuration for their specific applications. After – sales, customers can benefit from KUKA’s extensive warranty coverage, on – site maintenance services when required, and access to software updates (if applicable) to enhance the drive’s performance. This support ensures that the KSD1 – 16 continues to operate at its best throughout its lifespan.

Contact us for a customized solution tailored to your industrial automation needs with the reliable KUKA KSD1 – 16 servo drive.