Description

Product Overview

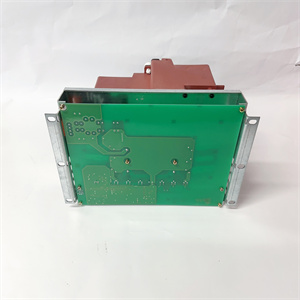

The ABB KUC755AE117 3BHB005243R0117 is a high-performance robot controller designed for ABB’s industrial robotics systems, particularly those in the IRC5 controller family. Engineered to manage the motion, logic, and communication of robotic arms, this controller serves as the “brain” of automated manufacturing systems, enabling precise control in applications such as pick-and-place, welding, painting, and assembly. The model KUC755AE117 (part number 3BHB005243R0117) is optimized for mid-to-large-scale robots, offering advanced features for flexibility, reliability, and scalability in demanding industrial environments.

As part of ABB’s IRC5 platform, the controller integrates seamlessly with ABB’s robot hardware (e.g., IRB series robots) and software tools (e.g., RobotStudio), providing a unified solution for automation. It supports multiple robots and external axes, making it suitable for complex cell setups where coordination between multiple devices is critical. The KUC755AE117 emphasizes real-time control, high-speed processing, and robust connectivity, ensuring smooth operation in 24/7 production lines across industries like automotive, electronics, and logistics.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | KUC755AE117 3BHB005243R0117 |

| Manufacturer | ABB |

| Product Type | Robot Controller (IRC5 Series) |

| Processor | Multi-core ARM processor (high-performance) |

| Memory | 4 GB RAM, 32 GB SSD |

| Communication Interfaces | Ethernet (1 Gbps), PROFINET, EtherCAT, USB 3.0, RS-485 |

| Robot Support | Up to 4 robots or 16 axes (including external axes) |

| Programming Languages | ABB RobotWare (RAPID), C++, Python (via plugins) |

| Safety Features | SafeMove2 (ISO 10218-1/2 compliant), emergency stop, safeguarded stop |

| Power Supply | 200–240 V AC (single-phase) or 380–480 V AC (three-phase) |

| Operating Temperature | 5°C to 45°C (ambient, non-condensing) |

| Dimensions (W×H×D) | Approx. 600 mm × 200 mm × 500 mm |

| Mounting Method | Rack-mounted or standalone cabinet |

| Certification | CE, UL, cUL, ISO 10218, IEC 61508 (SIL2-ready) |

KUC755AE117 3BHB005243R0117

Main Features and Advantages

1. Advanced Motion Control

- High Precision: Supports ABB’s TrueMove and QuickMove technologies for accurate path following (±0.02 mm repeatability) and high-speed motion, ideal for applications requiring both speed and precision (e.g., electronics assembly).

- Multi-Axis Coordination: Manages complex robot movements, including synchronized motion with external axes (e.g., conveyors, positioners).

2. Flexible Programming and Integration

- RobotWare Software Suite: Includes pre-installed software modules for specific applications (e.g., RobotWare-Painting, RobotWare-Welding), reducing programming time.

- Open Architecture: Supports custom plugins and third-party software via APIs, enabling integration with IoT platforms (e.g., ABB Ability™) for predictive maintenance and analytics.

3. Safety and Reliability

- SafeMove2: Built-in safety functions allow robots to operate alongside humans in collaborative setups, monitoring speed, position, and force to prevent collisions.

- Redundancy Options: Optional dual-core processing and redundant power supplies ensure continuous operation in critical applications (e.g., automotive body shops).

4. Scalability and Connectivity

- Modular Design: Expandable via I/O modules (e.g., DSQC 652), fieldbus adapters (e.g., DSQC 377A for PROFINET), and vision systems (e.g., ABB PickMaster).

- Industrial IoT Ready: Connects to ABB’s Ability™ Manufacturing Operations Management (MOM) for real-time data monitoring, remote diagnostics, and OEE (Overall Equipment Effectiveness) optimization.

KUC755AE117 3BHB005243R0117

Application Fields

The KUC755AE117 is deployed in a wide range of industries:

- Automotive: Controls spot welding, painting, and material handling robots in vehicle assembly lines.

- Electronics: Enables precise pick-and-place of tiny components (e.g., PCBs, semiconductors) with high repeatability.

- Logistics: Manages palletizing, depalletizing, and sorting robots in warehouses and distribution centers.

- Metal Fabrication: Supports robotic welding (MIG, TIG), cutting, and bending for metal processing.

- Food and Beverage: Controls hygienic robots for packaging, labeling, and quality inspection in cleanroom environments.

Key benefits include reduced cycle times, improved first-pass yield, and simplified retooling for product changeovers, making it a critical component in smart factory initiatives.

Related Products

- Robot Models: Compatible with ABB’s IRB 6700 (heavy-duty), IRB 4600 (medium payload), and IRB 1600 (small robot) series.

- Software Tools:

- RobotStudio: 3D simulation and programming software for offline robot programming.

- RobotWare-OS: The controller’s operating system, with regular updates for new features and security patches.

- Peripherals:

- DSQC 652 I/O Module: Provides digital inputs/outputs for connecting sensors and actuators.

- DSQC 345B Communication Module: Enables EtherCAT or PROFINET connectivity.

- IRC5 Teach Pendant: Handheld device for manual robot programming and jogging.

- Safety Solutions:

- SafeMove2 Software: Enhances collaborative robotics safety.

- GuardMaster Safety Relays: Integrated with the controller for emergency stop circuits.

Installation and Maintenance

Installation Steps:

- Mounting: Install the controller in a rack or standalone cabinet with proper ventilation (avoid direct sunlight or extreme temperatures).

- Cabling: Connect the robot arm via the Drive Module (e.g., KPS 6001), power supply, and Ethernet/fieldbus cables for communication with PLCs or HMIs.

- Software Setup: Use RobotStudio to configure the robot model, install application-specific software (e.g., RobotWare-Welding), and upload RAPID programs.

- Calibration: Perform robot calibration (e.g., using the MicroCal tool) to ensure accurate motion.

Maintenance Tips:

- Regular Checks: Monitor controller diagnostics via the teach pendant or RobotStudio for error logs, firmware updates, and disk space.

- Cooling System: Clean dust filters quarterly to prevent overheating (critical in dusty environments like metalworking).

- Backup: Schedule automatic backups of RAPID programs and system configurations to a USB drive or network drive.

- Spare Parts: Keep essential components on hand (e.g., power supplies, fan units) for quick replacement during downtime.

Product Guarantee

ABB offers a 2-year standard warranty for the KUC755AE117, covering defects in materials and workmanship. For extended reliability, customers can opt for ABB’s Service Agreements, which include proactive maintenance, priority technical support, and firmware updates. ABB’s global service network provides 24/7 emergency support, on-site repairs, and training programs to ensure optimal performance throughout the controller’s lifecycle.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.