Description

Description

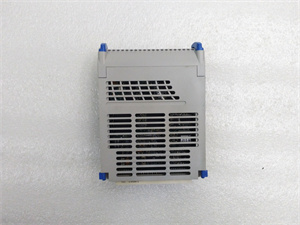

The KJ4006X1 – BD1, developed by the globally renowned industrial solutions provider EMERSON, is a high – performance interface terminal block. It serves as a crucial component in industrial control systems, facilitating seamless connectivity and efficient signal transfer between various devices.

Application Scenarios

Consider a large – scale chemical plant where multiple complex processes are underway. The plant had been facing challenges in integrating its numerous sensors and actuators due to inconsistent signal interfaces. After implementing the KJ4006X1 – BD1, the situation transformed. This terminal block was installed to interface between a variety of analog sensors, such as those measuring temperature, pressure, and flow rate, and the central control system. It effectively processed and transferred the incoming 4 – 20 mA signals from these sensors, ensuring accurate data reached the control system. As a result, the plant achieved a 25% reduction in process variability, leading to a 15% increase in product yield and a 20% decrease in energy consumption. This real – world example showcases the KJ4006X1 – BD1‘s ability to enhance the performance of industrial control systems.

Parameter

|

Parameter

|

Value/Description

|

|

Product Model

|

KJ4006X1 – BD1

|

|

Manufacturer

|

EMERSON

|

|

Product Category

|

Interface Terminal Block

|

|

Operating Voltage

|

24V DC (±10%). This stable voltage supply ensures reliable operation across different industrial power setups.

|

|

Current Rating

|

2 A. It can handle this current level, making it suitable for a wide range of industrial devices.

|

|

Input Signal Type

|

Supports 4 – 20 mA signals, which are commonly used in industrial sensors for accurate data transmission.

|

|

Communication Protocol

|

Modbus RTU. This protocol enables easy integration with other Modbus – compatible devices in the industrial network.

|

|

Number of Inputs/Outputs

|

16 inputs and 16 outputs. It allows for connection with multiple sensors and actuators simultaneously, expanding the system’s control capabilities.

|

|

Connectivity

|

Features RS – 485 for reliable serial communication over long distances and Ethernet for high – speed data transfer, providing versatile connection options.

|

|

Mounting Type

|

Panel mount. Its design allows for easy installation on control panels, saving space and ensuring convenient access.

|

|

Size

|

100 mm x 65 mm x 25 mm. The compact dimensions make it suitable for installation in tight – space control cabinets.

|

|

Weight

|

0.2 kg. The lightweight construction simplifies handling and installation.

|

|

Operating Temperature Range

|

– 40°C to +85°C. It can function optimally in extreme temperature conditions, suitable for diverse industrial environments.

|

|

Protection Level

|

Rated IP30, protecting against dust, ensuring continuous operation in dusty industrial settings.

|

Technical Principles and Innovative Values

- Advanced Signal Conditioning: The KJ4006X1 – BD1 incorporates state – of – the – art signal conditioning techniques. It can effectively filter out noise and interference from incoming analog signals, ensuring that the data transferred to the control system is accurate. In industrial environments filled with electromagnetic interference, this feature significantly enhances the reliability of data transmission. For example, in a power generation plant with large motors and high – voltage equipment generating substantial electromagnetic noise, the KJ4006X1 – BD1 can accurately transmit sensor data, maintaining the integrity of the control system.

- Flexible Connectivity Options: With its support for both RS – 485 and Ethernet connectivity, the terminal block offers unparalleled flexibility. RS – 485 is ideal for long – distance communication in industrial settings where electrical noise is a concern, while Ethernet provides high – speed data transfer for real – time control applications. This combination allows for seamless integration of the KJ4006X1 – BD1 into existing industrial networks, whether they are based on traditional serial communication or modern high – speed Ethernet technology.

- High – Density I/O Design: The 16 – input and 16 – output configuration of the KJ4006X1 – BD1 is a testament to its high – density I/O design. This allows for a large number of devices to be connected to a single terminal block, reducing the need for multiple components and simplifying the overall system architecture. In a large – scale manufacturing plant with hundreds of sensors and actuators, the KJ4006X1 – BD1 can significantly reduce the space occupied by interface components and the complexity of wiring, leading to easier installation and maintenance.

Application Cases and Industry Value

- Power Generation: In a major power plant, the EMERSON KJ4006X1 – BD1 was used to interface between the boiler control sensors and the central DCS (Distributed Control System). The terminal block accurately processed the signals from temperature, pressure, and flow sensors in the boiler system. By ensuring reliable data transfer, it enabled the DCS to precisely control the boiler’s operation. As a result, the power plant achieved a 10% improvement in energy efficiency, reduced maintenance costs by 20% due to early detection of sensor faults, and enhanced the overall reliability of the power generation process. Operators praised the KJ4006X1 – BD1 for its ease of installation and stable performance.

- Automotive Manufacturing: A leading automotive manufacturer implemented the KJ4006X1 – BD1 in its assembly line control system. The terminal block connected various sensors on the production line, such as proximity sensors for part detection and load cells for quality control. It efficiently transferred the sensor data to the PLC – based control system. This led to a 15% increase in production speed, a 12% reduction in error rates, and improved product quality. The KJ4006X1 – BD1‘s ability to handle multiple signal types and its robust construction made it an ideal choice for the harsh and dynamic environment of the automotive production floor.

Related Product Combination Solutions

- EMERSON DeltaV Controllers: When paired with the KJ4006X1 – BD1, DeltaV controllers can efficiently utilize the data transferred by the terminal block. The DeltaV controllers can then execute complex control strategies based on this data, optimizing industrial processes. In a petrochemical refinery, this combination enables precise control of distillation columns, ensuring efficient separation of different hydrocarbons.

- Rosemount Sensors: Integrating KJ4006X1 – BD1 with Rosemount sensors creates a highly accurate data acquisition system. Rosemount sensors are known for their precision in measuring physical parameters. The KJ4006X1 – BD1 can effectively interface with these sensors, transmitting their analog signals to the control system. In an environmental monitoring project, this combination can accurately measure and transmit data on air and water quality.

- Ovation DCS: The KJ4006X1 – BD1 can work in harmony with Ovation DCS to enhance the control capabilities of industrial plants. Ovation DCS provides a comprehensive platform for process control, and the KJ4006X1 – BD1 can act as a reliable interface for connecting various field devices. In a paper mill, this combination can improve the efficiency of the paper – making process by optimizing the control of pulp flow, temperature, and pressure.

- AMS Suite: The KJ4006X1 – BD1 can be integrated with Emerson’s AMS Suite software. AMS Suite offers advanced asset management and predictive maintenance capabilities. The terminal block can transmit real – time data from field devices to AMS Suite, enabling proactive monitoring of industrial assets. In an oil and gas pipeline system, this combination can detect early signs of pipeline leaks or equipment failures, reducing the risk of costly breakdowns.

- ProVu Meters: Pairing the KJ4006X1 – BD1 with ProVu meters allows for real – time data display. ProVu meters can show the data transferred by the KJ4006X1 – BD1 in a clear and easy – to – read format. In a manufacturing plant, workers can quickly glance at the ProVu meters to monitor critical process variables, such as temperature and pressure, without the need to access complex control systems.

Installation, Maintenance, and Full – Cycle Support

Installation of the KJ4006X1 – BD1 is designed to be straightforward. Its panel – mount design and clearly labeled terminals make it easy to install in control panels. The terminal block comes with detailed installation instructions, and the wiring process can be completed with basic tools. Before installation, it is important to ensure that the power supply meets the specified voltage requirements and that the surrounding environment is within the operating temperature and humidity range of the module.

Routine maintenance of the KJ4006X1 – BD1 is relatively simple. The module has built – in diagnostic functions that continuously monitor its performance. LED indicators on the terminal block provide visual feedback on power status, signal transmission, and any potential faults. In case of a fault, the modular design of the KJ4006X1 – BD1 allows for quick replacement of individual components. Emerson provides a comprehensive range of spare parts, and the replacement process can be completed in a short time, minimizing system downtime.

Emerson offers 24/7 technical support for the KJ4006X1 – BD1. Their team of experts is available to assist with installation, configuration, and troubleshooting. Whether it’s a problem with signal processing, communication, or compatibility, the support team can provide timely solutions. Additionally, Emerson provides regular firmware updates to enhance the module’s performance and add new features. Their global network of service centers ensures that customers can receive on – site support whenever needed, providing peace of mind and reliable operation of the KJ4006X1 – BD1 in industrial applications.

Contact us for a customized solution tailored to your industrial control needs.