Description

Product Overview

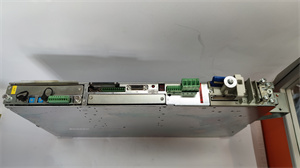

The GE IS420UCSCH2A – C – V0.1 – A is a high – performance dual – core controller within the esteemed Mark VIe series, crafted by General Electric. Engineered to meet the complex demands of modern industrial automation, this controller serves as a crucial component in various industrial setups.

This IS420UCSCH2A – C – V0.1 – A controller is designed to operate in tandem with the QNX Neutrino operating system, ensuring high – reliability and high – speed performance. It leverages EFA (Embedded Field Agent) technology, enabling seamless connection to Predix cloud – based applications for real – time data delivery. Although it lacks built – in application I/O capabilities, it can be effectively used within a redundancy set. In such a configuration, it gains access to all I/O networks linked to each controller in the set, thereby receiving vital input data. The IS420UCSCH2A – C – V0.1 – A is well – equipped to handle complex control tasks, making it a preferred choice for industries where precision and stability are of utmost importance.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS420UCSCH2A – C – V0.1 – A |

| Manufacturer | GE |

| Product Type | Dual – Core Controller |

| Processor | Intel EP80579 600 MHz |

| Memory | 4 GB DDR3 – 1333 SDRAM |

| Ethernet Ports | Six RJ45 |

| Redundancy Support | TMR, Simplex, Dual |

| Operating System Compatibility | QNX Neutrino |

| Application Suitability | IONet, Functional Safety Loops |

| Operating Temperature | 0 to 65 °C |

| Power Supply | 18 – 36 V dc, 12 – watt |

IS420UCSCH2A-C-V0.1-A

Main Features and Advantages

High – speed processing: The GE IS420UCSCH2A – C – V0.1 – A comes with an Intel EP80579 600 MHz processor. This powerful processor enables high – speed data processing, allowing it to manage complex industrial operations with ease. Whether it’s handling large amounts of sensor data or executing intricate control algorithms, the controller can keep up with the demands of real – time industrial processes.

Ample memory: With 4 GB DDR3 – 1333 SDRAM, the controller has sufficient memory to store and manage large datasets. This is beneficial for applications that require handling of extensive historical data, running complex software algorithms, or multitasking between different control functions. It ensures smooth operation even under heavy workloads, preventing system slowdowns or crashes.

Multiple communication ports: The six RJ45 Ethernet ports facilitate seamless communication with other industrial components. This high – level connectivity enables the IS420UCSCH2A – C – V0.1 – A to integrate into existing industrial networks effortlessly. It can communicate with sensors, actuators, other controllers, and monitoring systems, enhancing overall network efficiency and data flow within the industrial setup.

Redundancy options: Supporting various redundancy options such as TMR (Triple Modular Redundancy), simplex, and dual, the controller ensures operational safety. In critical industrial applications where downtime can be costly, these redundancy features minimize the risk of system failures. In a TMR configuration, for example, the controller can continue operating even if one of the modules fails, maintaining continuous control and monitoring of industrial processes.

Ample memory: With 4 GB DDR3 – 1333 SDRAM, the controller has sufficient memory to store and manage large datasets. This is beneficial for applications that require handling of extensive historical data, running complex software algorithms, or multitasking between different control functions. It ensures smooth operation even under heavy workloads, preventing system slowdowns or crashes.

Multiple communication ports: The six RJ45 Ethernet ports facilitate seamless communication with other industrial components. This high – level connectivity enables the IS420UCSCH2A – C – V0.1 – A to integrate into existing industrial networks effortlessly. It can communicate with sensors, actuators, other controllers, and monitoring systems, enhancing overall network efficiency and data flow within the industrial setup.

Redundancy options: Supporting various redundancy options such as TMR (Triple Modular Redundancy), simplex, and dual, the controller ensures operational safety. In critical industrial applications where downtime can be costly, these redundancy features minimize the risk of system failures. In a TMR configuration, for example, the controller can continue operating even if one of the modules fails, maintaining continuous control and monitoring of industrial processes.

Application Field

In power generation, the GE IS420UCSCH2A – C – V0.1 – A is extensively used for controlling gas turbines, steam turbines, and in combined – cycle power plants. It can precisely regulate the speed, temperature, and other critical parameters of these power – generating equipment. By maintaining optimal operating conditions, it helps in maximizing power generation efficiency and minimizing fuel consumption.

The manufacturing industry also benefits significantly from this controller. In automated production lines, it can manage robotic arms, conveyor belts, and other manufacturing equipment. It ensures synchronized operation of these components, reducing production errors and increasing throughput. For instance, in an automotive manufacturing plant, the IS420UCSCH2A – C – V0.1 – A can control the movement of robotic arms during the assembly process, ensuring accurate part placement.

In the process industries, such as chemical plants and oil refineries, the controller plays a vital role in process control. It can monitor and control variables like pressure, flow rate, and chemical composition. By maintaining tight control over these variables, it helps in ensuring product quality, safety, and compliance with industry regulations.

IS420UCSCH2A-C-V0.1-A

Related Products

- GE IS420UCSCH1A: Similar to the IS420UCSCH2A – C – V0.1 – A, it is also a Mark VIe controller. However, it may have different processing capabilities or port configurations. It could be a more basic version in the series, suitable for applications with less complex control requirements.

- GE IS220UCSAH1A: Designed for the Mark VI system, this controller serves a similar purpose but has its own unique features. It may have different power requirements or be optimized for different types of industrial applications, such as specific types of turbine control.

- GE IONet Applications: These are software applications that can be used in conjunction with the IS420UCSCH2A – C – V0.1 – A. They enhance the controller’s functionality, allowing for more complex control strategies and better integration with other parts of the industrial system.

- GE QNX Neutrino Operating System: The operating system on which the IS420UCSCH2A – C – V0.1 – A runs. Updates or different versions of this operating system can impact the controller’s performance and compatibility with other software and hardware components.

- GE Redundancy Sets Components: Other components that can be part of the redundancy set when the IS420UCSCH2A – C – V0.1 – A is used in a redundant configuration. These components work together to ensure high – availability and reliability in industrial operations.

Installation and Maintenance

Pre – installation preparation: Before installing the GE IS420UCSCH2A – C – V0.1 – A, ensure that the UCSC device is directly mounted onto a suitable installation base. Leave at least about 4 inches of air gap above and below the UCSC. Also, make sure that the working temperature envelope is maintained approximately 1 inch away from any point on the UCSC controller. Verify that the power supply meets the 18 – 36 V dc, 12 – watt requirements.

Maintenance recommendations: Regularly check the controller for any signs of physical damage, such as cracks or loose connections. Monitor the temperature of the operating environment to ensure it stays within the 0 – 65 °C range. Update the software and firmware as recommended by GE to benefit from the latest features, bug fixes, and security enhancements. If the controller is part of a redundancy set, periodically test the redundancy functionality to ensure its proper operation.

Product Guarantee

GE stands firmly behind the quality of the GE IS420UCSCH2A – C – V0.1 – A. The product undergoes strict quality – control procedures during manufacturing to meet high – industry standards. GE typically offers a warranty that covers manufacturing defects for a specified period. In case of any quality – related issues within the warranty period, GE’s global technical support team is readily available. They can provide detailed guidance on installation, troubleshooting, and, if necessary, arrange for the repair or replacement of the IS420UCSCH2A – C – V0.1 – A promptly. This reflects GE’s commitment to delivering reliable and high – performing products for industrial automation, ensuring long – term customer satisfaction.