Description

Product Overview

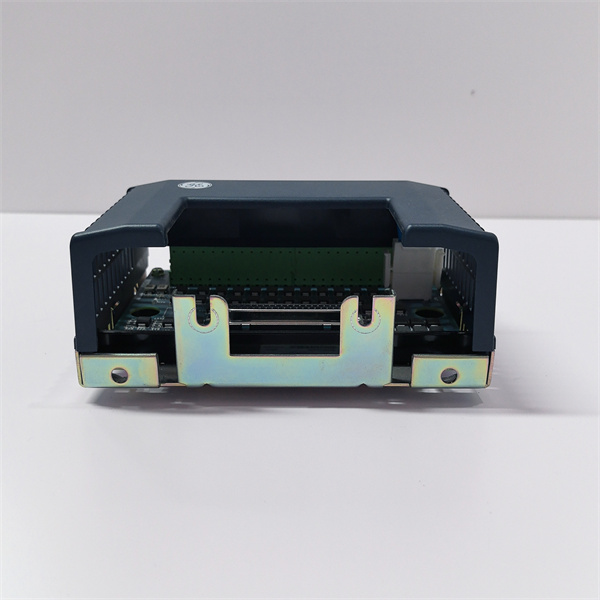

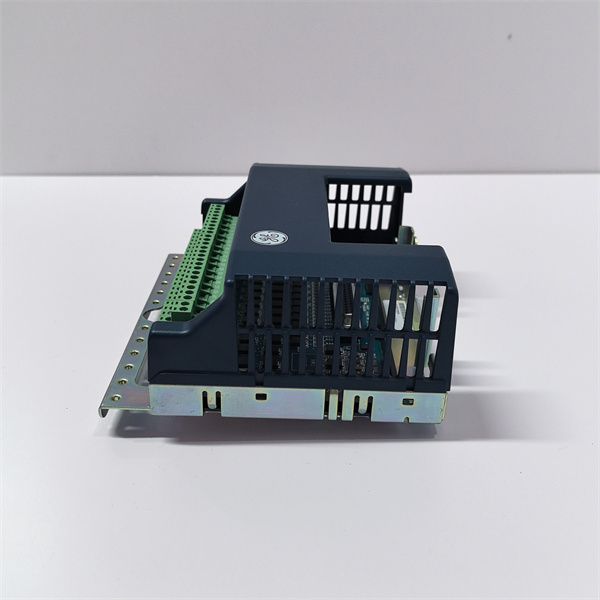

The General Electric IS410STCIS2A and IS400STCIS2AFF are integral components within GE’s industrial automation product lineup. The IS410STCIS2A is a compact contact input terminal board, designed specifically for use in GE’s Mark VIe series of distributed turbine control systems. It plays a crucial role in receiving and processing input signals from a wide range of field devices, acting as a bridge between the physical sensors and the control system.

With its 24 contact inputs, the IS410STCIS2A can handle multiple input signals simultaneously, making it suitable for complex industrial setups. It features a compact design, which is ideal for space – constrained environments where every bit of space counts. As for the IS400STCIS2AFF, while specific details are less prevalent, it is likely related in function, perhaps offering additional features or compatibility options within the same system framework. These products are positioned as reliable and efficient solutions for industries that require precise control and monitoring in their operations, enhancing the overall performance and reliability of the industrial automation systems they are a part of.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS410STCIS2A / IS400STCIS2AFF |

| Manufacturer | General Electric |

| Product Type | Contact Input Terminal Board (IS410STCIS2A) – nature of IS400STCIS2AFF less clear but likely related |

| Input Voltage (IS410STCIS2A) | 24 V DC |

| Number of Input Channels (IS410STCIS2A) | 24 |

| Mounting Options (IS410STCIS2A) | DIN – rail or flat mounting |

| Operating Temperature Range | – 20 °C to + 60 °C |

| Humidity Range | 5% – 95% non – condensing |

| Dimensions (IS410STCIS2A) | Compact (exact dimensions need to be sourced from product manual) |

| Compatibility | Works with GE Mark VIe series systems |

IS410STCIS2A IS400STCIS2AFF

Main Features and Advantages

Compact Design

The IS410STCIS2A has a compact form factor, making it highly suitable for installations where space is at a premium. This allows for easy integration into existing control panels or systems without the need for extensive re – engineering.

Multiple Input Channels

Featuring 24 contact inputs, it can interface with numerous field devices simultaneously. This enables comprehensive monitoring and control of a wide array of industrial processes, from sensing the status of switches to detecting the operation of various sensors.

Versatile Mounting

With options for both DIN – rail and flat mounting, the IS410STCIS2A offers flexibility in installation. This means it can be easily mounted in different types of enclosures or control cabinets, depending on the specific requirements of the industrial setup.

Noise Suppression

It is equipped with noise suppression features to protect against electrical interference. In industrial environments where electromagnetic interference is common, this ensures that the input signals are accurately received and processed, minimizing the risk of false readings or system malfunctions.

System Compatibility

Both the IS410STCIS2A and potentially the IS400STCIS2AFF are designed to work seamlessly with GE’s Mark VIe series systems. This compatibility ensures smooth integration within the overall industrial automation framework, enabling efficient communication and coordination between different components.

IS410STCIS2A IS400STCIS2AFF

Application Field

In the power generation industry, the GE IS410STCIS2A (and related IS400STCIS2AFF) can be used in gas turbine control systems. The 24 – channel contact inputs can monitor various signals such as the status of valves, sensors for temperature and pressure, and the operation of auxiliary equipment. This helps in precisely controlling the turbine’s operation, optimizing power output, and ensuring safe and reliable operation.

Chemical processing plants also benefit from these products. The IS410STCIS2A can receive input signals from sensors that monitor chemical levels, flow rates, and reaction conditions. By accurately processing these signals, it enables the control system to regulate the chemical processes, ensuring product quality and preventing any potential hazards.

In oil and gas refining, the compact and reliable nature of the IS410STCIS2A makes it suitable for use in monitoring and controlling equipment in refineries. It can interface with a variety of field devices, helping to manage the refining process efficiently, from the initial separation of crude oil components to the final production of refined products.

Water and wastewater treatment facilities can utilize these products to monitor the status of pumps, valves, and sensors that measure water quality parameters. The IS410STCIS2A can process the input signals and send them to the control system, which then adjusts the treatment process accordingly to ensure clean water output and proper wastewater disposal.

Related Products

- IS410STCIS4A: Likely a variant of the IS410STCIS2A, perhaps with different input voltage capabilities or additional features. It may be used in scenarios where the 24 – channel, 24 V DC input of the IS410STCIS2A is not sufficient, such as handling higher – voltage input signals or having more channels for a more extensive monitoring setup.

- IS410TBCIS1C: This product is related to the IS410STCIS2A within the Mark VIe system. It might be designed for a different type of input or control function, like handling a different type of contact input or being part of a redundant control setup, providing an alternative or complementary solution for specific industrial applications.

- IS220PPRFH1A: A Profibus PPRF pack. It can work in tandem with the IS410STCIS2A in industrial networks. The IS410STCIS2A receives input signals, and the IS220PPRFH1A can help in transmitting these signals over a Profibus network, enabling communication with other devices in a more complex industrial automation setup.

- IS220PSVOH1A: A servo control pack. In an industrial system where servo – controlled devices are present, the IS410STCIS2A can provide input signals related to the overall process, and the IS220PSVOH1A can use these signals to control the servo – motors accurately, ensuring smooth and precise operation of machinery.

- IS220PAICH1A: An analog in/out basic pack. While the IS410STCIS2A deals with contact inputs, the IS220PAICH1A can handle analog signals. In an industrial environment where both digital (contact – based) and analog signals need to be processed and integrated, these two products can work together to provide a comprehensive input/output solution for the control system.

Installation and Maintenance

Pre – installation preparation: Before installing the GE IS410STCIS2A (and considering potential use with IS400STCIS2AFF), carefully read the product installation manual. Ensure that the installation environment meets the specified temperature and humidity requirements. Check the power supply to confirm it can provide a stable 24 V DC for the IS410STCIS2A. If using DIN – rail mounting, verify that the DIN – rail is in good condition and properly installed. For flat mounting, prepare a suitable flat surface. Also, make sure to handle the product with care to avoid electrostatic discharge, which could damage the sensitive components.

Maintenance recommendations: Regularly inspect the IS410STCIS2A for any signs of physical damage, such as cracks or loose connections. Check the input channels to ensure they are accurately detecting signals. Clean the unit periodically to remove dust and debris, as these can affect its performance over time. If there are any software – related components (if applicable), keep the firmware updated to the latest version provided by GE. In case of any malfunction, refer to the troubleshooting section of the product manual or contact GE’s technical support team for assistance.

Product Guarantee

General Electric stands behind the quality of the IS410STCIS2A and, by association, the related IS400STCIS2AFF. GE ensures high – quality manufacturing through strict quality control processes. The products are typically covered by a standard warranty period, during which any manufacturing defects will be rectified. GE’s global network of technical support teams is available to assist customers. Whether it’s help with installation, troubleshooting, or general product – related queries, customers can rely on GE’s expertise. This guarantee not only reflects GE’s confidence in the product but also their commitment to ensuring that industrial automation systems powered by these components operate reliably and efficiently for years to come.