Description

Product Overview

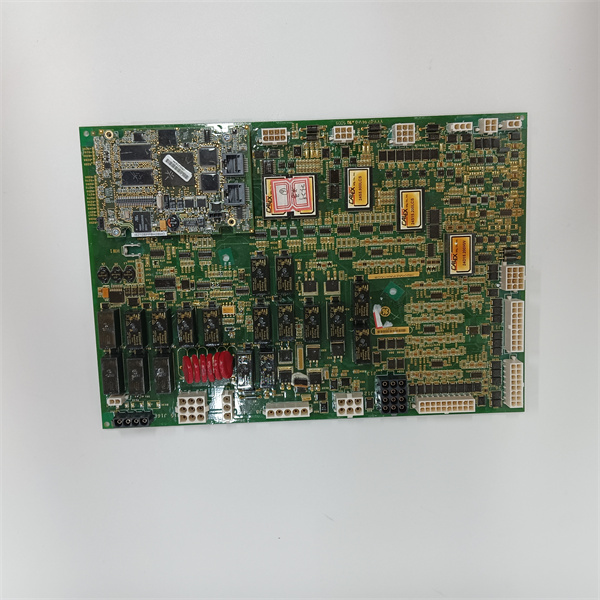

The GE IS230TNSVH3A is a high – performance analog input module meticulously designed for industrial control systems by General Electric. It stands as an integral component within the industrial automation landscape, ensuring seamless data acquisition and monitoring processes. As part of GE’s advanced product lineup, the IS230TNSVH3A is engineered to meet the rigorous demands of various industrial applications. It serves as a crucial link between field sensors and control systems, accurately capturing analog signals and converting them into digital data that can be processed and analyzed. This module plays a pivotal role in maintaining the efficiency and reliability of industrial operations, whether in manufacturing plants, power generation facilities, or process control industries.

Technical Specifications

|

Parameter Name

|

Parameter Value

|

|

Product Model

|

IS230TNSVH3A

|

|

Manufacturer

|

General Electric

|

|

Product Type

|

Analog Input Module

|

|

Input Channels

|

8

|

|

Input Range

|

– 10 to +10 VDC or 4 to 20 mA

|

|

Resolution

|

16 – bit

|

|

Sampling Rate

|

Up to 10 Hz per channel

|

|

Operating Voltage

|

24 VDC

|

|

Environmental Rating

|

IP20

|

|

Certifications

|

CE, UL, CSA

|

|

Module Dimensions

|

240 * 250 * 55 mm

|

|

Weight

|

1.5 kg

|

IS200AEPAH1ACB

Main Features and Advantages

Precise Data Acquisition

With 8 input channels and a high 16 – bit resolution, the GE IS230TNSVH3A can precisely measure and digitize analog signals. Whether it’s detecting minute changes in voltage or current, this module ensures that the data collected from sensors is highly accurate. For example, in a chemical processing plant, it can accurately monitor the flow rate of various chemicals using the 4 – 20 mA input range, enabling precise control of the production process.

Wide Input Range Compatibility

The ability to handle input ranges from – 10 to +10 VDC or 4 to 20 mA makes the IS230TNSVH3A extremely versatile. It can interface with a wide variety of sensors, from temperature sensors that output voltage signals to pressure sensors that use current signals. This compatibility reduces the need for additional signal conditioning equipment, simplifying the overall system design.

Robust Design for Industrial Environments

Rated IP20, the module is protected against solid objects such as dust, which is common in industrial settings. Operating on 24 VDC, it is designed to withstand electrical fluctuations typical in industrial power supplies. The CE, UL, and CSA certifications further attest to its safety and reliability, making it suitable for use in diverse industrial applications across different regions.

IS215WETAH1BB IS200WETAH1AGC

Application Field

Manufacturing Industry

In manufacturing plants, the GE IS230TNSVH3A is used to monitor and control various processes. For instance, in an automotive assembly line, it can be connected to sensors that measure the torque of robotic arms during the tightening of bolts. By accurately collecting and transmitting this data, it ensures that the assembly process is consistent and of high quality, reducing the risk of defective products.

Power Generation

Power plants, whether they are gas – fired, coal – fired, or hydro – powered, rely on the IS230TNSVH3A for monitoring critical parameters. It can be used to measure the temperature and pressure of steam in a steam turbine power plant. Based on the data collected, the control system can adjust the operation of the turbine to optimize power generation efficiency and prevent equipment failures.

Process Control Industries

Industries like chemical, petrochemical, and food and beverage use the GE IS230TNSVH3A extensively. In a petrochemical refinery, it can monitor the level of various petroleum products in storage tanks using level sensors that output analog signals. This data is then used to control the filling and emptying processes, ensuring smooth and safe operations.

Related Products

- GE IS230STCIH6A: While the GE IS230TNSVH3A focuses on analog input, the IS230STCIH6A might be related to discrete turbine control functions. They can be part of a larger GE industrial control system, where the IS230TNSVH3A provides analog data that the IS230STCIH6A can use in its control algorithms.

- GE IC695ALG600: An analog – to – digital converter module, similar to the IS230TNSVH3A in terms of handling analog signals. However, it may have different input channel numbers, resolution, or application focus. The IC695ALG600 might be more suitable for applications with different signal – handling requirements, but both can be used in industrial control setups to manage analog data.

- GE IC695ALG704: An analog output module, in contrast to the input – focused IS230TNSVH3A. In an industrial control loop, the IS230TNSVH3A can feed analog input data to a controller, which then uses the IC695ALG704 to send out analog control signals to actuators, completing the control process.

- GE IS200TBAOH1C: Another module in GE’s product range. Although details are scarce, it could potentially be used in a related industrial control context. It might be involved in tasks like signal conditioning or communication within the system, complementing the functionality of the IS230TNSVH3A.

- GE IS200STURH4AEC: This module may have different functions, perhaps related to turbine control or data processing. In a complex industrial control system, it can work in tandem with the IS230TNSVH3A, with the IS230TNSVH3A providing analog input data that the IS200STURH4AEC can further process or use for control purposes.

Installation and Maintenance

Pre – installation preparation: Before installing the GE IS230TNSVH3A, ensure that the power supply to the industrial control system is turned off. Check the installation location to ensure it meets the environmental requirements, such as being within the IP20 – rated conditions, free from excessive dust and moisture. Verify that the 24 VDC power supply is stable and properly configured. Also, confirm that the connections to the sensors and the control system are correctly wired according to the module’s specifications.

Maintenance recommendations: Regularly check the status of the IS230TNSVH3A by monitoring the data it collects. Ensure that the input signals are within the expected range. Clean the module periodically to remove any dust that may have accumulated, as dust can affect its performance over time. Check the power supply voltage regularly to ensure it remains at 24 VDC. In case of any abnormal data readings or module malfunctions, refer to the product manual for troubleshooting steps or contact GE’s technical support for assistance.

Product Guarantee

General Electric offers a comprehensive product guarantee for the GE IS230TNSVH3A. The module undergoes strict quality control during manufacturing to ensure its reliability and performance. GE provides a standard warranty period, during which any defects in materials or workmanship will be rectified at no cost to the customer. Their team of experienced technical experts is available to offer support for installation, configuration, and troubleshooting. In case of any issues with the IS230TNSVH3A, customers can rely on GE’s customer service to respond promptly and resolve the problem effectively. This commitment reflects GE’s confidence in the quality of the product and its dedication to providing a seamless experience for industrial users.