Description

Product Overview

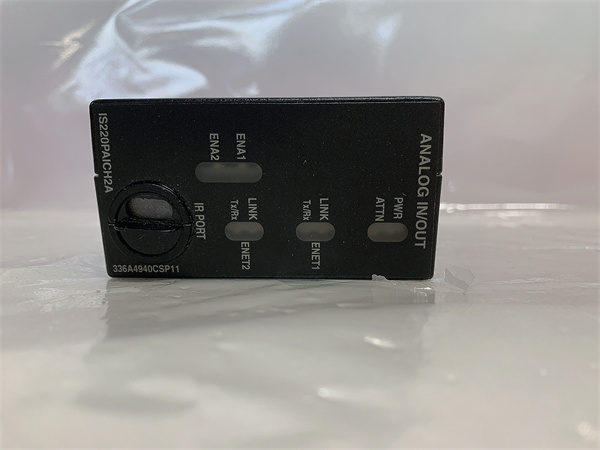

The GE IS230TNPAH2A is a high – performance analog input module crafted by General Electric, a global leader in industrial automation and power management solutions. Engineered for industrial automation systems, it occupies a pivotal position in scenarios where precise data acquisition and signal processing are of utmost importance.

As part of GE’s comprehensive range of industrial control components, the GE IS230TNPAH2A is designed to handle a variety of input signals. It can accurately measure and convert analog signals from sensors and other field devices into digital data that can be easily processed by the control system. This module is widely used in industrial control applications, acting as a reliable interface between the physical world of sensors and the digital control realm, ensuring seamless communication and accurate control.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS230TNPAH2A |

| Manufacturer | GE |

| Product Type | Analog Input Module |

| Input Channels | 8 channels |

| Input Range | – 10 V to + 10 V |

| Resolution | 16 – bit |

| Accuracy | ± 0.1% of reading |

| Sampling Rate | Up to 1 MHz |

| Communication Interface | Modbus RTU, Profibus DP |

| Power Supply | 24 V DC |

| Operating Temperature | – 40 °C to + 85 °C |

| Storage Temperature | – 55 °C to + 105 °C |

| Certification | CE, UL, CSA |

Main Features and Advantages

High – Resolution Data Acquisition

The GE IS230TNPAH2A boasts a 16 – bit resolution, enabling it to capture even the slightest variations in analog input signals. This high – resolution capability is crucial in applications where precision is key, such as in pharmaceutical manufacturing, where accurate monitoring of temperature, pressure, and flow rate is essential for maintaining product quality. It ensures that the control system receives highly detailed data, leading to more precise control actions.

Wide Input Range and Compatibility

With an input range of – 10 V to + 10 V, this module can handle a diverse set of analog signals from different types of sensors. Whether it’s a voltage – output sensor in a chemical plant or a current – output sensor in a power generation facility, the IS230TNPAH2A can interface with them effectively. This wide input range, combined with its compatibility with common industrial communication protocols like Modbus RTU and Profibus DP, makes it a versatile choice for various industrial setups.

Robust Design for Harsh Environments

Built to withstand the rigors of industrial environments, the GE IS230TNPAH2A has an operating temperature range from – 40 °C to + 85 °C. This allows it to be used in extreme cold regions, such as in Arctic oil and gas operations, or in high – temperature environments like steel mills. Additionally, its compliance with CE, UL, and CSA certifications ensures that it meets international safety and quality standards, providing users with confidence in its performance and reliability.

Application Field

Power Generation

In power generation plants, be it gas – fired, coal – fired, or hydroelectric, the GE IS230TNPAH2A plays a vital role. It can be used to monitor parameters such as turbine temperature, generator voltage, and fuel flow rate. For example, in a gas – turbine power plant, the module can receive analog signals from temperature sensors installed on the turbine blades. By accurately measuring these temperatures, the control system can adjust the fuel – air mixture to optimize combustion efficiency, reducing fuel consumption and emissions while ensuring stable power generation.

Manufacturing

In manufacturing industries, from automotive to electronics, the IS230TNPAH2A is used to monitor and control production processes. In an automotive assembly line, it can connect to sensors that measure the torque of bolts during the vehicle assembly process. The module’s high – accuracy data acquisition helps in ensuring that each bolt is tightened to the correct specification, improving the quality and safety of the vehicles produced. In an electronics manufacturing plant, it can monitor the temperature and humidity in the cleanroom environment, maintaining optimal conditions for the production of sensitive electronic components.

Process Industries

Industries such as chemical, petrochemical, and food and beverage rely on the GE IS230TNPAH2A for process control. In a chemical reactor, the module can receive analog signals from sensors that measure the concentration of reactants, the pH level of the reaction mixture, and the pressure inside the reactor. Based on this accurate data, the control system can adjust the flow rates of reactants, the addition of catalysts, and other process variables to ensure efficient and safe chemical reactions. In a food and beverage factory, it can monitor the temperature and pressure during the pasteurization process, ensuring the quality and safety of the products.

Related Products

- GE IS230SNAIH2A: It is also an analog input module from GE. However, it may have different input channel configurations or be optimized for different types of analog signals compared to the IS230TNPAH2A. For example, it could have a different input range or resolution, making it suitable for applications with specific signal – handling requirements.

- GE IS230SRTDH2A: This is an RTD (Resistance Temperature Detector) input module. Unlike the IS230TNPAH2A which is a general – purpose analog input module, the IS230SRTDH2A is specifically designed to interface with RTD sensors for accurate temperature measurement. It is used in applications where precise temperature monitoring is crucial, such as in industrial ovens or refrigeration systems.

- GE IS230SNRTH2A: A module with a different function, perhaps related to signal conditioning or communication in a specific industrial control context. It may work in tandem with the IS230TNPAH2A in a larger control system, but its role is more focused on tasks like filtering and amplifying signals before they are processed by the main control unit.

- GE IS230TNCIH4C: Another module in the IS230 series. It might have a different set of features, such as different communication protocols supported or a different number of input channels. It could be designed for applications that require a more customized approach to analog input handling compared to the standard IS230TNPAH2A.

- GE IS230STAOH2A: An analog output module, which has the opposite function of the IS230TNPAH2A. While the IS230TNPAH2A is used for inputting and processing analog signals, the IS230STAOH2A is used to send out analog control signals to actuators or other devices in the industrial control system, such as valves or motors.

Installation and Maintenance

Pre – installation preparation: Before installing the GE IS230TNPAH2A, carefully review the installation manual provided by GE. Ensure that the power supply available at the installation site is 24 V DC as required by the module. Check the physical location where it will be installed for any signs of excessive dust, moisture, or mechanical stress. If it is to be mounted on a DIN – rail, make sure the DIN – rail is in good condition and properly installed. Verify that the communication cables to be connected to the module for Modbus RTU or Profibus DP communication are of the correct type and in good working order.

Maintenance recommendations: Regularly inspect the IS230TNPAH2A for any signs of physical damage, such as cracks in the casing or loose connections. Clean the module periodically, especially if it is installed in a dusty environment, using a dry, lint – free cloth to prevent dust accumulation that could affect its performance. Monitor the input signals using appropriate monitoring tools to ensure that the module is accurately measuring and converting analog signals. If any issues are detected, such as incorrect readings or communication failures, refer to the troubleshooting guide in the user manual. In case of complex problems, contact GE’s technical support for further assistance.

Product Guarantee

GE stands firmly behind the quality of the GE IS230TNPAH2A analog input module. The product undergoes rigorous testing during the manufacturing process to meet high – quality standards. GE offers a standard warranty period, during which any defects in materials or workmanship will be rectified free of charge. Their experienced technical support team is available to assist customers with installation, configuration, and any technical issues that may arise during the product’s lifespan. Whether it’s a problem with the module’s input channels, communication interfaces, or overall performance, GE is committed to providing timely and effective solutions. This gives customers confidence in their investment and ensures the long – term, reliable operation of the IS230TNPAH2A in various industrial applications.