Description

Product Overview

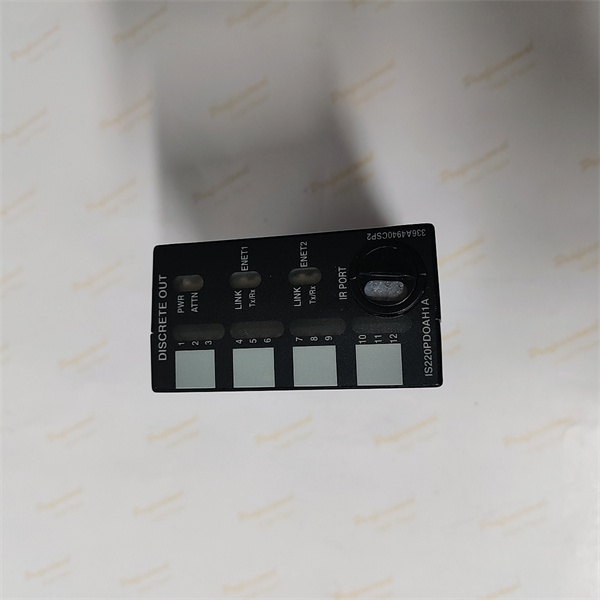

The GE IS220PDOAH1A is a discrete output module, part of the renowned GE Mark VIe series. Engineered by General Electric, a global leader in industrial technology, this module serves as a critical link in distributed turbine control systems. Its primary function is to offer an electrical interface between up to two input – output Ethernet networks and a discrete output terminal board.

This module is designed to handle complex control tasks with precision. With the ability to control up to 12 relays and accept terminal – board – specific feedback, it enables seamless integration with various industrial devices. Embedded within the GE IS220PDOAH1A is a processor board equipped with state – of – the – art components. This includes high – speed processors, along with flash and RAM memory, ensuring efficient data handling and quick response times. It plays a pivotal role in industrial automation setups, especially those related to power generation and heavy – machinery control, by providing reliable and accurate control signals.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS220PDOAH1A |

| Manufacturer | GE |

| Product Type | Discrete Output Module |

| Series | Mark VIe |

| Processor | 32 – bit RISC CPU 266 mHz |

| Memory | Flash and RAM (specific capacities not provided in source but present for data handling) |

| Communication Ports | Two Ethernet ports (10/100BaseTX for connection with UDH and IONet) |

| Input Voltage | +32 V dc to 18 V dc |

| Operating Temperature | – 30 °C to 65 °C (- 22 °F to 149 °F) |

| Output Control | Can control up to 12 relays |

| Terminal Compatibility | Compatible with specific terminal boards for feedback |

| Power Consumption | [Not specified, but operates with provided input voltage range] |

| Physical Dimensions | [Not given in source, but designed to fit standard industrial setups] |

| Weight | [Not provided in source] |

IS220PDOAH1A

Main Features and Advantages

High – Performance Control: The GE IS220PDOAH1A‘s 32 – bit RISC CPU running at 266 mHz allows for rapid processing of control commands. This ensures that the relays are controlled precisely and in a timely manner, crucial for applications where split – second decisions are required, such as in power generation plants during load – shedding operations.

Flexible Connectivity: With two Ethernet ports, it can easily integrate into existing industrial networks. Whether it’s connecting to a central control system or communicating with other I/O modules, the Ethernet connectivity enables seamless data transfer. This flexibility makes it suitable for a wide range of industrial setups, from small – scale manufacturing units to large – scale power generation facilities.

Reliable Feedback Mechanism: Its ability to accept terminal – board – specific feedback provides an added layer of reliability. The module can monitor the status of the connected devices through this feedback, allowing for real – time adjustments. For example, in a manufacturing process, if a relay – controlled actuator fails to operate as expected, the feedback will prompt the GE IS220PDOAH1A to take corrective action, reducing downtime.

Redundancy – Friendly: As part of the Mark VIe series, which is known for its support of redundant systems, the GE IS220PDOAH1A can be used in setups where system reliability is of utmost importance. In critical applications like aerospace manufacturing or oil refineries, redundant configurations of this module can be implemented to ensure continuous operation even in the event of a component failure.

Flexible Connectivity: With two Ethernet ports, it can easily integrate into existing industrial networks. Whether it’s connecting to a central control system or communicating with other I/O modules, the Ethernet connectivity enables seamless data transfer. This flexibility makes it suitable for a wide range of industrial setups, from small – scale manufacturing units to large – scale power generation facilities.

Reliable Feedback Mechanism: Its ability to accept terminal – board – specific feedback provides an added layer of reliability. The module can monitor the status of the connected devices through this feedback, allowing for real – time adjustments. For example, in a manufacturing process, if a relay – controlled actuator fails to operate as expected, the feedback will prompt the GE IS220PDOAH1A to take corrective action, reducing downtime.

Redundancy – Friendly: As part of the Mark VIe series, which is known for its support of redundant systems, the GE IS220PDOAH1A can be used in setups where system reliability is of utmost importance. In critical applications like aerospace manufacturing or oil refineries, redundant configurations of this module can be implemented to ensure continuous operation even in the event of a component failure.

Application Field

Power Generation: In power plants, the GE IS220PDOAH1A is used to control various electrical components. It can manage the switching of circuit breakers, control the operation of pumps and fans in the cooling systems, and regulate the excitation of generators. For instance, during the start – up and shut – down procedures of a gas – fired power plant, this module ensures that the relays controlling the fuel supply and exhaust systems operate in the correct sequence.

Industrial Manufacturing: In manufacturing facilities, it plays a key role in controlling automated production lines. It can be used to operate solenoid valves that control the flow of fluids in chemical manufacturing processes or to manage the movement of robotic arms in automotive assembly lines. The precise control and feedback capabilities of the GE IS220PDOAH1A help in maintaining high – quality production standards and minimizing errors.

Transportation Infrastructure: In transportation – related industrial applications, such as in the control systems of subway trains or cargo handling equipment in ports, this module is utilized. It can control the relays that operate the brakes, doors, and other critical components of subway trains, ensuring safe and efficient transportation. In port cargo handling, it manages the movement of cranes and conveyor belts, optimizing the flow of goods.

Industrial Manufacturing: In manufacturing facilities, it plays a key role in controlling automated production lines. It can be used to operate solenoid valves that control the flow of fluids in chemical manufacturing processes or to manage the movement of robotic arms in automotive assembly lines. The precise control and feedback capabilities of the GE IS220PDOAH1A help in maintaining high – quality production standards and minimizing errors.

Transportation Infrastructure: In transportation – related industrial applications, such as in the control systems of subway trains or cargo handling equipment in ports, this module is utilized. It can control the relays that operate the brakes, doors, and other critical components of subway trains, ensuring safe and efficient transportation. In port cargo handling, it manages the movement of cranes and conveyor belts, optimizing the flow of goods.

IS220PDOAH1A

Related Products

GE IS220PDIAH1A: This is an I/O module with two Ethernet ports. While the GE IS220PDOAH1A focuses on discrete output, the IS220PDIAH1A likely combines both input and output capabilities, providing a more comprehensive I/O solution for industrial control systems.

GE IS220PAICH1A: An analog I/O pack designed for the GE Mark VI series. It is used for handling analog signals, unlike the GE IS220PDOAH1A which deals with discrete outputs. Together, they can be used in complex industrial setups where both analog and discrete signals need to be managed.

GE IS220PDIOH1A: Another I/O component module with two Ethernet ports, a local processor, and a data – acquisition board. It may offer more advanced data – handling features compared to the GE IS220PDOAH1A, potentially being used in applications that require more complex data processing and control algorithms.

GE IS210DRTDH1A: Although details are scarce, it is likely part of the same product ecosystem. It may have different functionality, perhaps related to data acquisition or signal conditioning, and can be used in conjunction with the GE IS220PDOAH1A to enhance the overall performance of an industrial control system.

GE IS210DTCIH1A: Similar to the above, it is likely another module within the GE industrial control product line. It may be designed for specific tasks such as digital signal processing or communication protocol handling, complementing the discrete output functions of the GE IS220PDOAH1A.

GE IS220PAICH1A: An analog I/O pack designed for the GE Mark VI series. It is used for handling analog signals, unlike the GE IS220PDOAH1A which deals with discrete outputs. Together, they can be used in complex industrial setups where both analog and discrete signals need to be managed.

GE IS220PDIOH1A: Another I/O component module with two Ethernet ports, a local processor, and a data – acquisition board. It may offer more advanced data – handling features compared to the GE IS220PDOAH1A, potentially being used in applications that require more complex data processing and control algorithms.

GE IS210DRTDH1A: Although details are scarce, it is likely part of the same product ecosystem. It may have different functionality, perhaps related to data acquisition or signal conditioning, and can be used in conjunction with the GE IS220PDOAH1A to enhance the overall performance of an industrial control system.

GE IS210DTCIH1A: Similar to the above, it is likely another module within the GE industrial control product line. It may be designed for specific tasks such as digital signal processing or communication protocol handling, complementing the discrete output functions of the GE IS220PDOAH1A.

Installation and Maintenance

Pre – installation preparation: Before installing the GE IS220PDOAH1A, ensure that the selected terminal board is safely installed. The module should be directly inserted into the terminal – board connector. Use the threaded bolts near the Ethernet ports to mechanically secure the I/O module. These bolts fit into the dedicated mounting brackets of the terminal board. Ensure that no right – angled force is applied to the DC – 37 pin connector between the I/O module and the terminal board. According to the system configuration, connect 1 – 2 network cables. The I/O module can function on either port, but when using a dual – connection, it is common to connect ENET1 to the network related to the R controller. Insert the connector on the side of the I/O module to connect it to the power source. Since the I/O component has built – in soft – start capabilities to control current surges, there is no need to disconnect the power on the cable before insertion. Use the ToolboxST application to configure the I/O module as required.

Maintenance recommendations: Regularly check the GE IS220PDOAH1A for any signs of physical damage, such as cracks in the casing or loose connections. Monitor the operating temperature, as it should remain within the specified – 30 °C to 65 °C range. Clean the module periodically to remove dust and debris that could affect its performance. Check the status of the relays and ensure that they are operating correctly. If any issues are detected, refer to the product manual for troubleshooting steps or contact GE’s technical support.

Maintenance recommendations: Regularly check the GE IS220PDOAH1A for any signs of physical damage, such as cracks in the casing or loose connections. Monitor the operating temperature, as it should remain within the specified – 30 °C to 65 °C range. Clean the module periodically to remove dust and debris that could affect its performance. Check the status of the relays and ensure that they are operating correctly. If any issues are detected, refer to the product manual for troubleshooting steps or contact GE’s technical support.

Product Guarantee

GE stands firmly behind the quality of the GE IS220PDOAH1A. The module undergoes rigorous quality – control procedures during manufacturing to meet high – industry standards. GE typically provides a comprehensive warranty, covering manufacturing defects for a specified period. In case of any quality – related issues within the warranty period, GE’s global technical support team is readily available. They can offer detailed guidance on installation, troubleshooting, and, if necessary, arrange for the repair or replacement of the GE IS220PDOAH1A. This reflects GE’s commitment to customer satisfaction and the long – term reliability of the product in industrial applications.