Description

Product Overview

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

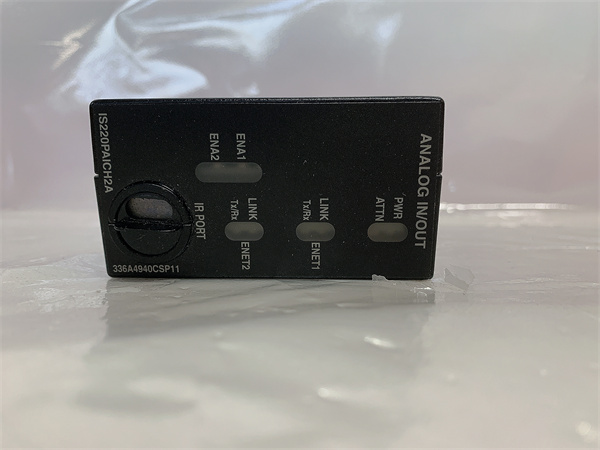

| Product Model | IS220PAICH2A |

| Manufacturer | GE |

| Product Type | Communication Module |

| Communication Rate | 100/1000Mbps |

| Input Signal Type | Analog |

| Output Signal Capacity | 200mA |

| Power Supply | AC220V (input stability: ≤10%, frequency stability: ≤2%) |

| DC Output Voltage (24V) | Output fluctuation ≤5% |

| DC Output Voltage (48V) | Output fluctuation ≤10% |

| Physical Dimensions | [Specify dimensions if available] |

| Installation Method | Backplane 插装 |

| Operating Temperature Range | [Mention temperature range if known] |

IS220PAICH2A

Main Features and Advantages

High – speed communication: With a communication rate of 100/1000Mbps, the IS220PAICH2A enables rapid data transfer between different parts of the automation system. This high – speed communication is essential for real – time control and monitoring, allowing for quick response to process changes and ensuring optimal system performance.

Analog signal handling: Capable of handling analog input and output signals with a 200mA capacity, the module offers precise control over industrial processes. This is particularly useful in applications where accurate measurement and control of variables such as temperature, pressure, and flow are critical.

Good compatibility: It is highly compatible with other components in GE’s industrial control product line, as well as with many third – party devices, making it easy to integrate into existing automation systems. This compatibility reduces the complexity of system design and implementation.

Application Field

The GE IS220PAICH2A communication module finds extensive applications across various industries. In the chemical industry, it is used to control and monitor chemical reactions, ensuring the safety and efficiency of production processes. For example, in a petrochemical plant, the module can transmit data related to temperature, pressure, and chemical composition in real – time, allowing operators to make timely adjustments.

In the oil and gas sector, the IS220PAICH2A is crucial for remote monitoring and control of oil wells, pipelines, and refineries. It enables seamless communication between field devices and control centers, facilitating the efficient operation of the entire oil and gas production chain.

The module also plays a significant role in the manufacturing industry. In a large – scale manufacturing plant, it can be used to connect different production lines and automated machinery, ensuring smooth coordination and synchronization of production processes. This helps to improve productivity, reduce downtime, and enhance product quality.

Moreover, in power generation facilities, the GE IS220PAICH2A is utilized to monitor and control power generation equipment, such as turbines and generators, ensuring stable power supply.

IS220PAICH2A

Related Products

IC200PWR102: A power supply module by GE. It provides the necessary electrical power for the operation of components like the IS220PAICH2A in an industrial control setup. The IS220PAICH2A depends on a stable power supply from IC200PWR102 to function properly.

IS220PDIAH1A: Another GE module. It may be used in a similar DCS or PLC environment as the IS220PAICH2A, but it likely has different input/output characteristics or communication protocols, catering to different requirements within the industrial control system.

CI854K01 (ABB): Although from a different brand (ABB), it serves a similar communication – related function in ABB’s automation systems. It can be considered as an alternative in cases where ABB – based systems are preferred over GE – based ones.

MPRC086444 – 005 (ABB): This ABB product might be related to communication or control in ABB’s industrial setups. While it has a different brand origin than the IS220PAICH2A, it can be used for comparison purposes when evaluating communication solutions for industrial applications.

Installation and Maintenance

Maintenance recommendations: Regularly inspect the IS220PAICH2A module for any signs of physical damage, such as cracks or loose connections. Clean the module periodically to remove dust and debris that could affect its performance. Monitor the communication performance of the module, and if there are any abnormal delays or data transfer errors, check for possible issues like network congestion or faulty cables. In case of any suspected module failure, follow GE’s official troubleshooting procedures to identify and resolve the problem.