Description

Product Overview

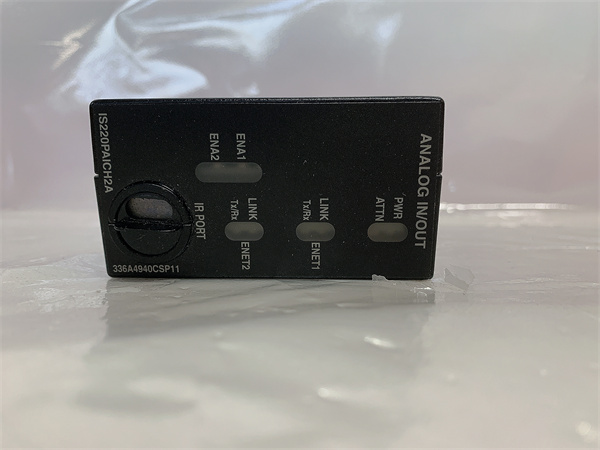

The GE IS220PAICH2A is a high – performance analog input/output interface module designed by General Electric for its Mark VIe turbine control system. As a crucial component within the industrial automation and control ecosystem, this module is engineered to handle the complex and precise requirements of turbine operations. It serves as a vital link between the physical sensors and actuators in the turbine system and the central control unit, enabling seamless data acquisition and control signal transmission.

The GE IS220PAICH2A is specifically crafted to process analog signals with high accuracy. It can interface with a wide range of sensors that measure critical parameters such as temperature, pressure, and flow rate in gas and steam turbines. By converting these physical measurements into digital signals that can be easily processed by the control system, the module allows for real – time monitoring and precise control of the turbine’s operation. This ensures that the turbine operates at peak efficiency, while also providing the necessary safeguards to prevent potential failures and ensure safety. Its integration into the Mark VIe system further enhances the overall reliability and performance of the turbine control setup, making it an indispensable part of modern power generation and industrial processes that rely on turbines.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS220PAICH2A |

| Manufacturer | GE |

| Product Type | Analog Input/Output Interface Module |

| Input Voltage Range | -10 V to 10 V |

| Output Voltage Range | -10 V to 10 V |

| Resolution | 16 – bit |

| Number of Input Channels | 8 |

| Number of Output Channels | 8 |

| Sampling Rate | Up to 1000 samples per second |

| Communication Protocol | Genius Bus |

| Operating Temperature Range | -20 °C to +55 °C |

| Humidity Range | 5% – 95% (non – condensing) |

| Dimensions | 17.8 cm x 10.2 cm x 3.8 cm |

| Weight | 0.8 kg |

IS220PAICH2A

Main Features and Advantages

High – precision signal processing: The GE IS220PAICH2A boasts a 16 – bit resolution, which allows for highly accurate analog – to – digital and digital – to – analog conversion. This high level of precision ensures that the data collected from sensors and the control signals sent to actuators are extremely accurate, enabling precise control of turbine operations. For example, it can accurately measure minute changes in temperature or pressure, which is crucial for maintaining optimal turbine performance.

Multiple channels: With 8 input and 8 output channels, the module offers great flexibility in connecting to a variety of sensors and actuators. This enables it to handle multiple parameters simultaneously, reducing the need for additional interface modules and simplifying the overall system design. It can be used to monitor and control different aspects of the turbine, such as fuel flow, blade position, and exhaust gas temperature, all within a single module.

Fast sampling rate: The module has a sampling rate of up to 1000 samples per second, ensuring that it can capture rapid changes in the analog signals. This real – time data acquisition capability is essential for applications where quick response times are required, such as in the event of sudden changes in load or abnormal operating conditions. It allows the control system to react promptly and make necessary adjustments to maintain stable turbine operation.

Reliable communication: The IS220PAICH2A uses the Genius Bus communication protocol, which provides a reliable and high – speed data transfer mechanism. This ensures seamless integration with other components in the Mark VIe system, enabling efficient data sharing and coordinated control. The communication protocol also offers error – checking and correction features, enhancing the overall reliability of the system.

Wide operating range: Designed to operate in a temperature range of -20 °C to +55 °C and a humidity range of 5% – 95% (non – condensing), the module can withstand harsh industrial environments. This makes it suitable for use in a variety of applications, from power plants in extreme climates to industrial facilities with challenging operating conditions.

IS220PAICH2A

Application Field

The GE IS220PAICH2A is predominantly used in power generation plants that utilize gas and steam turbines. In these facilities, it plays a crucial role in monitoring and controlling the turbine’s operation. For instance, it can measure the temperature of the turbine blades, the pressure of the steam or gas, and the flow rate of the fuel. Based on this data, the control system can adjust the turbine’s operation to optimize power generation efficiency, reduce fuel consumption, and minimize emissions.

In the oil and gas industry, the module is used in turbine – driven compressors and pumps. It helps in monitoring the performance of these critical equipment by measuring parameters such as pressure, flow, and temperature. By ensuring the efficient operation of these turbines, it contributes to the smooth running of the oil and gas production and transportation processes.

The IS220PAICH2A also finds applications in industrial manufacturing processes that rely on turbines for power or mechanical drive. For example, in large – scale manufacturing plants, it can be used to control the speed and performance of turbines that drive conveyor belts, robotic arms, or other production equipment. This helps in maintaining consistent production quality and increasing overall productivity.

Related Products

- GE IS220PAICH1A: A related model in the same series, likely with similar functionality but may have some differences in specific features or specifications. It could serve as an alternative or a complementary module depending on the specific requirements of the turbine control system.

- GE IS220PPRFH1B: This is a PROFIBUS Master Gateway I/O module that can work in conjunction with the IS220PAICH2A. While the IS220PAICH2A focuses on analog input/output, the IS220PPRFH1B facilitates communication with other devices on the PROFIBUS network, enabling a more comprehensive and integrated control system.

- GE IS200SPIDG1A: An accessory ID terminal board that can be used with the IS220PAICH2A to provide additional functionality or improve the connection and installation process. It may help in organizing and managing the wiring and connections associated with the analog input/output module.

- GE IS220UCSAH1A: Another module in the GE product line that can be part of the same turbine control system. It may handle different aspects of the control system, such as power supply management or digital signal processing, and can work in harmony with the IS220PAICH2A to ensure the overall operation of the system.

- GE IS220TRTDH1A: A thermocouple and RTD input module that can be used alongside the IS220PAICH2A. It is specifically designed for handling temperature – related inputs from thermocouples and resistance temperature detectors, while the IS220PAICH2A can handle a broader range of analog signals, creating a more complete solution for turbine parameter monitoring and control.

Installation and Maintenance

Pre – installation preparation: Before installing the GE IS220PAICH2A, ensure that the power to the system is turned off to prevent any electrical hazards. Carefully inspect the module for any visible signs of damage during transit. Familiarize yourself with the installation manual, which provides detailed instructions on how to properly mount the module onto the appropriate chassis or rack. Check the compatibility of the module with the existing control system, including the power supply requirements and communication interfaces. Make sure that all the sensors and actuators that will be connected to the module are properly calibrated and in good working condition.

Maintenance recommendations: Regularly monitor the IS220PAICH2A for any abnormal behavior, such as incorrect readings or communication errors. Check the indicator lights on the module to quickly identify any issues. Periodically clean the module to remove dust and debris, as these can affect its performance over time. Inspect the connections of all cables and wires to ensure they are secure. If any problems are detected, refer to the troubleshooting section of the product manual. Consider performing regular calibration of the module to maintain its accuracy, especially if it is used in applications where precise measurements are critical. In case of complex issues, contact GE’s technical support team for assistance.

Product Guarantee

GE stands firmly behind the quality of the IS220PAICH2A. The product comes with a comprehensive quality assurance program. During the specified warranty period, if the module is found to have defects in materials or workmanship, GE will provide free repair or replacement services. Their dedicated technical support team is readily available to assist customers with any installation – related queries, troubleshooting complex issues, or providing advice on optimizing the module’s performance. GE’s commitment to quality and customer satisfaction reflects its confidence in the IS220PAICH2A and its ability to perform reliably in diverse and demanding industrial applications. This ensures that customers can rely on the module for their critical turbine control needs, knowing that they have the support of a trusted industry leader.