Description

Product Overview

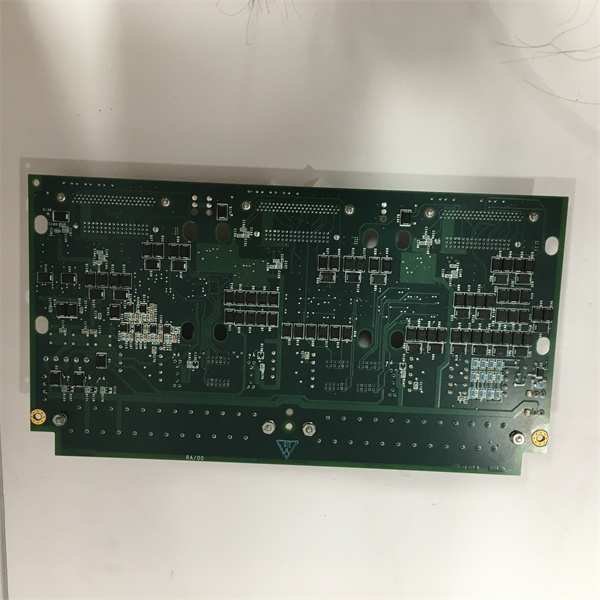

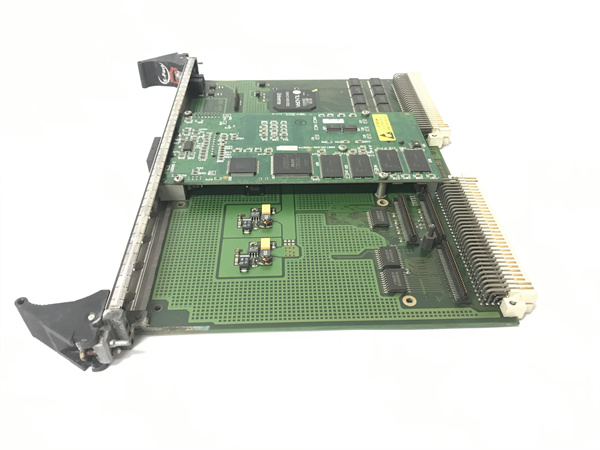

The GE IS215VCMIH2BB is a pivotal VME bus master controller board within GE’s esteemed Mark VI turbine control system series. Engineered with precision, it plays a fundamental role in industrial automation, especially in scenarios involving gas, steam, and wind turbine control systems. This board serves as a crucial communication interface, facilitating seamless data exchange between the controller and I/O boards. It also manages the identification of boards within the rack and their associated terminal boards, ensuring organized and efficient system operation. As part of the Mark VI series, which is renowned for its reliability and advanced control capabilities, the IS215VCMIH2BB contributes significantly to enhancing the overall performance and stability of turbine – related control processes. It is designed to handle complex data traffic and control signals, making it an essential component for optimizing the operation of industrial power generation and distribution systems.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS215VCMIH2BB |

| Manufacturer | GE |

| Product Type | VME Bus Master Controller Board |

| Series | Mark VI |

| Board Type | 6U high VME board, 0.787 inches wide |

| Processor | Texas Instruments TMS320C32 (32 – bit digital signal processor) |

| Memory | 32 KB dual – port memory (32 – bit transfer configuration), 256k x 32 SRAM, 512k x 8 – VCMIH B (flash memory) |

| Communication Interfaces | 3 IONet 10Base2 Ethernet ports (BNC connection, 10 Mbits/sec), 1 RS – 232C serial port (D – type plug connector, 9600 baud) |

| Input Voltage | [Specify the applicable input voltage range, if available] |

| Output Voltage | [Specify the output voltage details, if relevant] |

| Operating Temperature | 0 °C – 45 °C |

| Dimensions | 15.9 cm high x 10.2 cm wide |

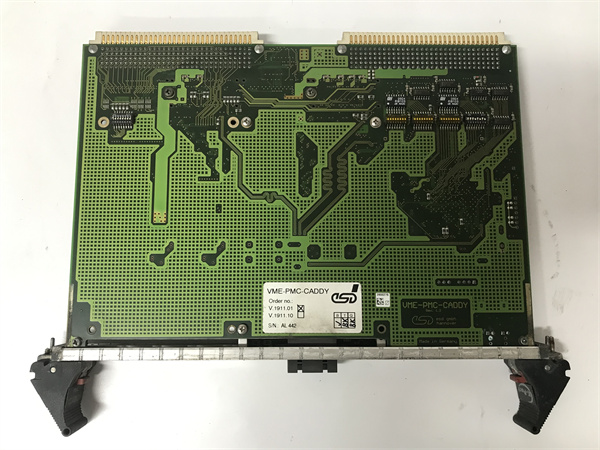

VME-PMC-CADDY

Main Features and Advantages

Robust Communication Capabilities

The GE IS215VCMIH2BB comes equipped with multiple communication interfaces. Its three IONet 10Base2 Ethernet ports enable high – speed data transfer, which is crucial for real – time monitoring and control in industrial settings. The 10 Mbits/sec speed ensures that data related to turbine operations, such as sensor readings and control commands, can be transmitted quickly and accurately. The inclusion of an RS – 232C serial port allows for additional connectivity options, facilitating communication with other devices that may not support Ethernet. This versatility in communication interfaces makes it easier to integrate the board into existing industrial automation networks.

Precise Data Processing

Powered by the Texas Instruments TMS320C32 32 – bit digital signal processor, the IS215VCMIH2BB is capable of handling complex data processing tasks. This high – performance processor can quickly analyze sensor data, execute control algorithms, and make real – time decisions. Whether it’s processing data related to turbine speed, temperature, or pressure, the board can ensure that the control system responds promptly and accurately, optimizing the performance of the turbine and reducing the risk of operational failures.

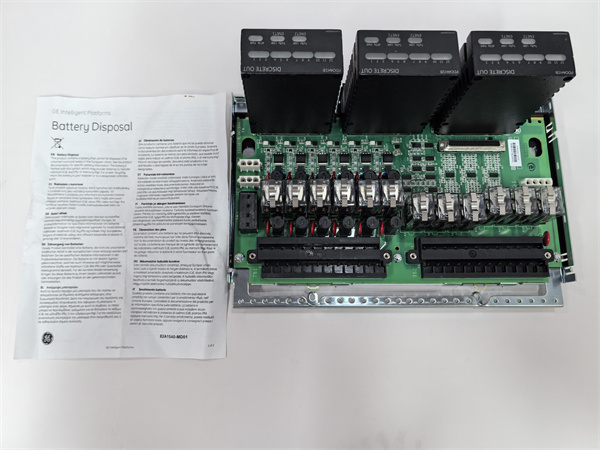

Efficient Board Management

As a VME bus master, the GE IS215VCMIH2BB manages the IDs of boards within the rack and associated terminal boards. This efficient board management system streamlines the operation of the entire control system. By clearly identifying each component, it becomes easier to troubleshoot any issues that may arise. For example, if there is a problem with a specific I/O board, the IS215VCMIH2BB can quickly pinpoint the board based on its ID, saving time and effort during maintenance and repair processes.

High Reliability in Design

With its conformal coated PCB, the IS215VCMIH2BB is well – equipped to withstand harsh industrial environments. The conformal coating protects the board from dust, moisture, and other contaminants, ensuring its reliable operation over an extended period. Additionally, the board’s design includes built – in diagnostic features, such as monitoring and alarming of internal power buses. This allows for early detection of potential issues, such as power supply problems, enabling proactive maintenance to prevent system failures.

IS215WETAH1BB IS200WETAH1AGC

Application Field

In the power generation industry, the GE IS215VCMIH2BB is widely used in gas, steam, and wind turbine control systems. In gas turbine power plants, it plays a critical role in monitoring and controlling the combustion process, ensuring efficient fuel utilization and minimizing emissions. By processing data from various sensors, it can adjust the fuel – air ratio in real – time, optimizing the performance of the gas turbine.

In steam turbine power plants, the IS215VCMIH2BB is responsible for controlling the steam flow, turbine speed, and generator output. It ensures that the steam turbine operates at its optimal efficiency, maximizing power generation. For wind turbines, the board helps in regulating the pitch of the blades and controlling the generator speed based on wind conditions. This ensures that the wind turbine can capture the maximum amount of wind energy while protecting the equipment from damage due to excessive wind speeds.

Moreover, in industrial manufacturing plants that use turbines for power generation or mechanical drive applications, the GE IS215VCMIH2BB is essential for maintaining the smooth operation of the turbines. It enables precise control of the turbines, which in turn supports the reliable operation of the manufacturing processes, ensuring consistent product quality.

Related Products

- IS215VCMIH1: An earlier version of the VCMI board. It has a different set of features compared to the IS215VCMIH2BB. For example, it may have fewer IONet ports or different memory configurations, making it suitable for applications with less demanding communication and data – handling requirements.

- IS420UCSBH1A: A UCSB controller module from GE. It works in tandem with the IS215VCMIH2BB in the Mark VIe system. While the IS215VCMIH2BB focuses on communication and board management, the IS420UCSBH1A is more involved in executing specific application – control system logic.

- IS215ACLE: An application control layer module in GE’s product lineup. It can be used in combination with the IS215VCMIH2BB in certain industrial automation setups. The IS215ACLE is a microprocessor – powered controller that can handle various communication – related tasks, complementing the functions of the IS215VCMIH2BB.

- IS200VCMIH2BCC: Another board related to the Mark VI system. It may have similar functionality to the IS215VCMIH2BB but could differ in terms of specific features, such as input/output capabilities or processing speed, making it suitable for different application scenarios within the turbine control domain.

- IS215UCVEM10A: This product might have a connection with the IS215VCMIH2BB in terms of system integration. It could be involved in aspects like voltage regulation or signal conditioning that support the overall operation of the system where the IS215VCMIH2BB is used.

Installation and Maintenance

Pre – installation preparation: Before installing the GE IS215VCMIH2BB, ensure that the installation environment meets the specified temperature and humidity requirements. Check the power supply to confirm it is within the appropriate range for the board. Clean the installation area to prevent dust and debris from affecting the board’s performance. When installing the board in the VME rack, make sure to align it correctly with the connectors and secure it firmly using the appropriate mounting hardware. Also, double – check all the communication and power cable connections to ensure they are properly plugged in.

Maintenance recommendations: Regularly inspect the IS215VCMIH2BB for any signs of physical damage, such as cracks or loose components. Check the status of the LEDs on the board to monitor its operational health. If any LEDs indicate an issue, refer to the product manual for troubleshooting steps. Clean the board periodically to remove any accumulated dust, as this can affect heat dissipation and potentially lead to performance issues. Additionally, keep the firmware of the board up – to – date to benefit from the latest improvements in functionality and stability. If any problems persist, contact GE’s technical support for further assistance.

Product Guarantee

GE offers a comprehensive product guarantee for the IS215VCMIH2BB. The company stands behind the quality of the board, ensuring that it is free from defects in materials and workmanship. There is a standard warranty period during which, if the board malfunctions due to non – user – induced reasons, GE will provide repair or replacement services at no cost. Their dedicated technical support team is available to assist customers with any queries regarding installation, operation, or maintenance. GE’s commitment to quality and customer satisfaction means that users can rely on the IS215VCMIH2BB to perform reliably in their industrial applications, with the assurance that any issues will be promptly addressed.