Description

Product Overview

The GE IS215UCVEH2AE is a crucial component within GE’s industrial control product portfolio, specifically designed for use in turbine control systems. It is part of the Mark VIe series, which is renowned for its advanced automation and control capabilities in power generation and other heavy – industrial applications. This module serves as a high – performance controller, responsible for processing and managing critical control signals and data related to turbine operations. It interfaces with various sensors and actuators, ensuring seamless communication to maintain the optimal performance and safety of the turbine. By accurately executing control algorithms, the GE IS215UCVEH2AE enables precise regulation of turbine speed, power output, and other essential parameters, playing a vital role in enhancing the efficiency and reliability of industrial processes.

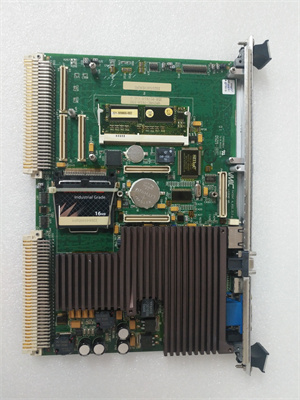

The GE VMIVME – 017614 – 132 (also identified as 350 – 017614 – 132D) is a versatile single – board computer module. It is engineered to be a key building block in industrial automation and data – acquisition systems. As part of the VMIC product line, it offers powerful computing capabilities, allowing it to handle complex tasks such as real – time data processing, control logic execution, and communication management. The module is designed to integrate seamlessly with other components in a VMEbus – based system, enabling efficient data transfer and system – wide coordination. Whether it’s used in manufacturing plants to control production lines or in research facilities for data – intensive experiments, the GE VMIVME – 017614 – 132 provides the processing power and flexibility required to meet diverse industrial and scientific needs.

Technical Specifications

| Parameter Name | GE IS215UCVEH2AE | GE VMIVME – 017614 – 132 |

|---|---|---|

| Product Model | IS215UCVEH2AE | VMIVME – 017614 – 132 (350 – 017614 – 132D) |

| Manufacturer | General Electric | General Electric |

| Product Type | Turbine Control Module | Single – Board Computer Module |

| Processor | [Specific Processor Model, e.g., High – performance embedded processor] | [e.g., Intel – based processor, depending on version] |

| Memory | [Specify RAM and Flash Memory Capacity, e.g., 256 MB RAM, 128 MB Flash] | [e.g., Up to 1 GB DDR RAM] |

| Communication Interfaces | Ethernet, Serial Ports, VMEbus | Ethernet (10/100/1000Base – T), VMEbus, PMC Expansion Interface |

| Input/Output Channels | Multiple analog and digital I/O channels for turbine – related signals | Varies based on expansion capabilities, supports various I/O cards via PMC slots |

| Operating Temperature Range | – 40°C to + 70°C | – 40°C to + 85°C |

| Dimensions | [Provide Length x Width x Height, e.g., 150 mm x 100 mm x 30 mm] | [e.g., 160 mm x 100 mm x 25 mm] |

| Weight | [Specify in grams or kilograms, e.g., 0.4 kg] | [e.g., 0.35 kg] |

| Power Supply | [e.g., 24 VDC] | [e.g., 5 VDC, 12 VDC] |

| Data Transfer Rate | High – speed for real – time turbine control | Up to 1 Gbps for Ethernet, high – speed within VMEbus |

IS215UCVEH2AE VMIVME-017614-132 350-017614-132D

Main Features and Advantages

GE IS215UCVEH2AE

Advanced control algorithms: The GE IS215UCVEH2AE is equipped with sophisticated control algorithms specifically tailored for turbine operations. These algorithms enable precise regulation of turbine speed, load sharing, and power output, ensuring stable and efficient operation even under varying operating conditions. This level of control is essential for maximizing power generation efficiency and minimizing wear and tear on turbine components.

Reliable communication: With multiple communication interfaces, including Ethernet and VMEbus, the IS215UCVEH2AE ensures reliable and high – speed communication with other system components. It can quickly exchange data with sensors, actuators, and other control modules, enabling real – time monitoring and control of the turbine. This seamless communication reduces the risk of data loss or delays, enhancing the overall reliability of the turbine control system.

Robust design: Built to withstand harsh industrial environments, the GE IS215UCVEH2AE has a rugged construction. It can operate within a wide temperature range and is resistant to electrical noise, vibrations, and dust. This robust design ensures long – term reliable operation, reducing maintenance requirements and downtime in critical industrial applications.

Reliable communication: With multiple communication interfaces, including Ethernet and VMEbus, the IS215UCVEH2AE ensures reliable and high – speed communication with other system components. It can quickly exchange data with sensors, actuators, and other control modules, enabling real – time monitoring and control of the turbine. This seamless communication reduces the risk of data loss or delays, enhancing the overall reliability of the turbine control system.

Robust design: Built to withstand harsh industrial environments, the GE IS215UCVEH2AE has a rugged construction. It can operate within a wide temperature range and is resistant to electrical noise, vibrations, and dust. This robust design ensures long – term reliable operation, reducing maintenance requirements and downtime in critical industrial applications.

GE VMIVME – 017614 – 132

Powerful computing performance: The GE VMIVME – 017614 – 132 offers powerful computing capabilities, thanks to its high – performance processor and ample memory. It can handle complex data – processing tasks, such as real – time analytics, machine – learning algorithms, and control – logic execution, with ease. This makes it suitable for applications that require high – speed and accurate data processing, such as advanced manufacturing automation and scientific research.

Flexible expansion options: The module features a PMC expansion interface, which allows users to customize its functionality by adding various I/O cards. This flexibility enables it to adapt to different application requirements, whether it’s adding more analog or digital I/O channels, communication interfaces, or specialized processing capabilities. It provides a cost – effective solution for building scalable and customized industrial automation systems.

High – speed communication: With support for high – speed Ethernet and VMEbus communication, the VMIVME – 017614 – 132 enables fast data transfer within the system. This ensures that data can be quickly shared between different components, enabling real – time control and monitoring. The high – speed communication also allows for seamless integration with other devices and systems, enhancing the overall connectivity and interoperability of the industrial automation setup.

Flexible expansion options: The module features a PMC expansion interface, which allows users to customize its functionality by adding various I/O cards. This flexibility enables it to adapt to different application requirements, whether it’s adding more analog or digital I/O channels, communication interfaces, or specialized processing capabilities. It provides a cost – effective solution for building scalable and customized industrial automation systems.

High – speed communication: With support for high – speed Ethernet and VMEbus communication, the VMIVME – 017614 – 132 enables fast data transfer within the system. This ensures that data can be quickly shared between different components, enabling real – time control and monitoring. The high – speed communication also allows for seamless integration with other devices and systems, enhancing the overall connectivity and interoperability of the industrial automation setup.

IS215UCVEH2AE VMIVME-017614-132 350-017614-132D

Application Field

GE IS215UCVEH2AE

Power generation: In power plants, the GE IS215UCVEH2AE is widely used in gas and steam turbine control systems. It plays a crucial role in optimizing power generation by precisely controlling turbine operations. For example, it can adjust the fuel supply and steam flow to match the grid demand, ensuring stable power output and efficient energy conversion. It also monitors critical turbine parameters, such as temperature, pressure, and vibration, to detect potential issues early and prevent costly breakdowns.

Industrial manufacturing: In industries that use turbines for mechanical drive applications, such as oil refineries, chemical plants, and paper mills, the IS215UCVEH2AE is used to control and monitor turbine – driven equipment. It ensures the smooth operation of turbines, which are essential for powering pumps, compressors, and other machinery. By maintaining optimal turbine performance, it helps improve production efficiency, reduce energy consumption, and enhance product quality.

Industrial manufacturing: In industries that use turbines for mechanical drive applications, such as oil refineries, chemical plants, and paper mills, the IS215UCVEH2AE is used to control and monitor turbine – driven equipment. It ensures the smooth operation of turbines, which are essential for powering pumps, compressors, and other machinery. By maintaining optimal turbine performance, it helps improve production efficiency, reduce energy consumption, and enhance product quality.

GE VMIVME – 017614 – 132

Manufacturing automation: In manufacturing plants, the GE VMIVME – 017614 – 132 is used to control and automate production processes. It can manage the operation of robotic arms, conveyor belts, and other automated equipment, ensuring precise and efficient production. By processing real – time data from sensors and executing control logic, it can optimize production schedules, improve product quality, and increase productivity.

Data acquisition and monitoring: The module is well – suited for data – acquisition systems in various industries. It can collect data from multiple sensors, such as temperature, pressure, flow, and position sensors, and transmit this data to a central control system for analysis. In applications such as environmental monitoring, quality control, and process optimization, the VMIVME – 017614 – 132 enables real – time data collection and analysis, providing valuable insights for decision – making.

Research and development: In scientific research facilities, the GE VMIVME – 017614 – 132 is used for data – intensive experiments and simulations. It can handle complex data – processing tasks, such as data analysis, algorithm development, and model validation. Its powerful computing capabilities and flexible expansion options make it a valuable tool for researchers in fields such as engineering, physics, and biology.

Data acquisition and monitoring: The module is well – suited for data – acquisition systems in various industries. It can collect data from multiple sensors, such as temperature, pressure, flow, and position sensors, and transmit this data to a central control system for analysis. In applications such as environmental monitoring, quality control, and process optimization, the VMIVME – 017614 – 132 enables real – time data collection and analysis, providing valuable insights for decision – making.

Research and development: In scientific research facilities, the GE VMIVME – 017614 – 132 is used for data – intensive experiments and simulations. It can handle complex data – processing tasks, such as data analysis, algorithm development, and model validation. Its powerful computing capabilities and flexible expansion options make it a valuable tool for researchers in fields such as engineering, physics, and biology.

Related Products

For GE IS215UCVEH2AE

- GE IS215UCVEM06A: Another turbine control module in the Mark VIe series. It shares some similarities with the IS215UCVEH2AE but may have different I/O configurations or control – algorithm focuses. It can be used as an alternative or in complementary setups for turbine control systems, depending on specific application requirements.

- GE IS215UCVGM06A: A UCV controller board that works in conjunction with the IS215UCVEH2AE in Mark VIe systems. It provides additional processing power and control functions, enhancing the overall performance and capabilities of the turbine control system.

- GE IS215UCVEC1A: A communication – interface module designed to facilitate data exchange between the IS215UCVEH2AE and other components in the system. It ensures reliable and high – speed communication, enabling seamless integration of the turbine control module with other parts of the industrial automation setup.

For GE VMIVME – 017614 – 132

- GE VMIVME – 7698: A similar single – board computer module in the VMIC product line. It offers different processor options and features, providing users with more choices based on their specific computing and application requirements. It can be used in place of the VMIVME – 017614 – 132 or in combination with it for more complex industrial automation systems.

- GE VMIVME – 5565: A VMEbus – based data – acquisition module that can be used in conjunction with the VMIVME – 017614 – 132 for enhanced data – acquisition capabilities. It provides additional analog and digital I/O channels, enabling more comprehensive data collection from sensors and other devices.

- GE VMIVME – 3140: A communication – interface module that expands the communication options of the VMIVME – 017614 – 132. It supports various communication protocols, such as Profibus, Modbus, and Ethernet/IP, enabling seamless integration with a wide range of industrial devices and systems.

Installation and Maintenance

Pre – installation preparation

For GE IS215UCVEH2AE: Before installing the GE IS215UCVEH2AE, ensure that the turbine control system is powered off and all safety precautions are in place. Check the installation environment to ensure it meets the temperature, humidity, and vibration requirements specified by the manufacturer. Verify that the VMEbus rack or enclosure where the module will be installed is clean and free from dust and debris. Prepare all the necessary cables and connectors for communication and power connections, and ensure they are in good condition. Follow the detailed installation instructions provided in the product manual to properly mount the module in the designated slot and make all the required connections.

For GE VMIVME – 017614 – 132: Before installing the GE VMIVME – 017614 – 132, power off the VMEbus – based system and ensure a static – free environment. Check the system’s power supply to confirm it can provide the required voltage and current for the module. Inspect the VMEbus backplane and the module’s connectors for any damage. If using PMC expansion cards, ensure they are properly seated and compatible with the VMIVME – 017614 – 132. Carefully insert the module into the appropriate slot on the VMEbus backplane, following the manufacturer’s guidelines, and make all the necessary power and communication connections.

Maintenance recommendations

For GE IS215UCVEH2AE: Regularly monitor the operating status of the GE IS215UCVEH2AE by checking the indicator lights and system diagnostics. Clean the module periodically to remove dust and debris that could affect its performance. Check the communication connections to ensure reliable data transfer. If any abnormal behavior or error messages are detected, refer to the product manual for troubleshooting steps. Periodically update the module’s firmware to benefit from the latest performance improvements and bug fixes. In case of hardware failures, contact GE’s technical support for repair or replacement options.

For GE VMIVME – 017614 – 132: Regularly check the temperature and fan operation of the GE VMIVME – 017614 – 132 to ensure proper cooling. Monitor the data – transfer rates and communication status to detect any potential issues. Clean the module and its connectors regularly to prevent dust accumulation, which can cause electrical problems. If using PMC expansion cards, check their functionality periodically. Keep the module’s firmware up – to – date to maintain optimal performance. In case of any malfunctions, follow the troubleshooting procedures provided in the product manual or seek assistance from GE’s technical support team.

Product Guarantee

GE stands firmly behind the quality and reliability of both the GE IS215UCVEH2AE and the GE VMIVME – 017614 – 132. These products are manufactured using high – quality materials and advanced manufacturing processes, and they undergo rigorous testing to ensure compliance with industry standards. GE offers a comprehensive product guarantee, typically including a warranty period during which any defects in materials or workmanship will be addressed free of charge. In the event of a product failure within the warranty period, GE will provide prompt repair or replacement services. Additionally, GE’s team of experienced technical experts is available to offer support for installation, configuration, and troubleshooting. This commitment to quality and customer service reflects GE’s confidence in the performance and durability of these products, providing customers with peace of mind and ensuring long – term satisfaction.