Description

Product Overview

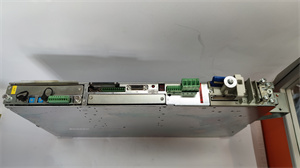

The GE IS215UCVEH2AB is a high – performance VME controller board, integral to the Mark VI series by General Electric. Engineered for industrial automation, it serves as a powerful computing and control hub within complex industrial systems.

This 6U – high, single/single – dual – width, single – board computer is designed to execute turbine application codes with precision. It communicates with other turbine I/O boards via the VME bus when placed in a control module. The IS215UCVEH2AB features an Intel Celeron 300 MHz microprocessor, enabling efficient data processing and control operations. It runs on the QNX operating system, a reliable choice for high – performance industrial applications. The board also has various status LED indicators on its faceplate, which help in monitoring its operational status easily.

The VMIVME – 7614 – 132 is also a significant component in this context. It’s a VMEbus single – board computer. Initially developed for GE’s industrial automation, it comes with features like support for multiple operating systems such as Windows NT, Windows 2000, Linux, VxWorks, QNX, and Solaris. It has a CompactFlash option of up to 512 megabytes for data storage and multiple programmable 16 – bit timer modules, enhancing its versatility for different industrial applications. The 350 – 007614 – 132C might be a related part number, perhaps denoting a specific configuration or version of the VMIVME – 7614 – 132 or having some connection to the overall system where these components are used.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS215UCVEH2AB |

| Manufacturer | General Electric |

| Product Type | VME Controller Board |

| Processor | Intel Celeron 300 MHz |

| Operating System | QNX |

| Memory | 32 MB DRAM (also available with 16 MB flash memory option) |

| Communication Interface | VME bus |

| Redundancy Applications | Simplex or triple modular redundant |

| Required VME Slots | Two |

| Status LED Description | Displays rotating LED patterns, 3 LEDs under top set screw |

| Cooling Method | Forced air cooling |

| Dimensions | Designed to fit 6U VME rack |

| Weight | [No specific value found, but likely designed for easy handling in industrial installations] |

| Certifications | Meets relevant industrial standards |

IS215UCVGH1A

| Parameter Name | Parameter Value |

|---|---|

| Product Model | VMIVME – 7614 – 132 |

| Manufacturer | Abaco Systems (originally developed for GE industrial automation) |

| Product Type | VMEbus Single – Board Computer |

| Processor | Based on single – issue Celeron Socket 370 processor |

| Memory | Up to 1.5 GB DDR SDRAM (varies by configuration) |

| Communication Interface | Ethernet (dual – gigabit options available), VMEbus P2 for HD/floppy drive connection |

| Expansion Slots | One PCI – X, 66 MHz PMC expansion slot |

| Storage | Up to 512 MB IDE CompactFlash (optional) |

| Timer Modules | Three programmable 16 – bit timer modules |

| Operating Temperature | 0 °C to 65 °C (rated temperature range) |

| Dimensions | Designed for VMEbus installations |

| Weight | [No specific value found, but suitable for industrial use] |

| Certifications | Meets relevant industrial standards |

Main Features and Advantages

High – Performance Processing

The IS215UCVEH2AB‘s Intel Celeron 300 MHz processor and the VMIVME – 7614 – 132‘s processing capabilities ensure quick data processing. This allows for rapid response to input signals and efficient execution of control algorithms in industrial processes, such as turbine control in power generation plants.

Reliable Operating System

With QNX as the operating system for IS215UCVEH2AB, it offers high – reliability and real – time performance. QNX is designed to handle the demanding requirements of industrial applications, minimizing the risk of system failures and ensuring smooth operation.

Flexible Memory Options

The IS215UCVEH2AB‘s availability in 32 MB DRAM or 16 MB flash memory configurations gives users the flexibility to choose according to their data storage and processing needs. The VMIVME – 7614 – 132‘s significant memory capacity and storage options like CompactFlash also contribute to its versatility.

Multiple Communication Interfaces

Both components support multiple communication interfaces. The IS215UCVEH2AB uses the VME bus for communication within the industrial control system, while the VMIVME – 7614 – 132 has Ethernet and other interfaces. This enables seamless integration with other devices and systems, facilitating data transfer and control across the industrial network.

Durable Design

Designed for industrial use, these components are built to withstand harsh environments. They can endure temperature variations, humidity, and electromagnetic interference commonly found in industrial settings, ensuring long – term reliable operation.

IS215UCVGH1A

Application Field

In power generation, the GE IS215UCVEH2AB and related VMIVME – 7614 – 132 are crucial for turbine control. They manage the operation of turbines, processing data from various sensors to adjust turbine speed, power output, and other parameters. This ensures efficient power generation and stable power supply.

In the oil and gas industry, these components can be used in remote terminal units (RTUs). They control and monitor equipment such as pumps, compressors, and valves in pipelines and refineries. The high – performance processing and reliable communication features are essential for maintaining the integrity of the oil and gas production process.

Manufacturing industries also benefit from these components. They can be integrated into automated production lines to control robotic arms, conveyor belts, and other manufacturing equipment. The ability to handle complex control algorithms and communicate effectively with other devices enhances production efficiency and product quality.

Related Products

- IS215UCVEM01A: Similar to the IS215UCVEH2AB, it is also a UCVE controller in the Mark VI series. However, it might have some differences in specific features or performance characteristics, providing users with an alternative option depending on their requirements.

- IC200CPU001: A different CPU module by GE. While the IS215UCVEH2AB is part of the Mark VI series with specific functions related to VME – based control, the IC200CPU001 may be designed for other types of industrial control systems or applications with different processing and interface requirements.

- IS215ACLEH1BC: This could be an interface or control – related board. It may work in tandem with the IS215UCVEH2AB to perform additional functions, such as handling specific communication protocols or providing extra control capabilities within the industrial system.

- VMIVME – 2540: Another module in the VMIC/GE Fanuc product line. It has the ability to function as an intelligent counter controller, which is different from the main functions of the VMIVME – 7614 – 132. It can be used in applications where precise counting and control based on counting are required, complementing the VMIVME – 7614 – 132 in more complex industrial setups.

- IS215VCMIH2B: A VME communication interface card. It can enhance the communication capabilities of the IS215UCVEH2AB – based system. By providing additional communication paths or better – optimized data transfer, it helps in integrating the system more effectively with other components in a large – scale industrial automation environment.

Installation and Maintenance

Pre – installation preparation: Before installing the GE IS215UCVEH2AB and VMIVME – 7614 – 132, carefully check the power supply to ensure it meets the voltage and current requirements of the components. The installation area should be clean, free from dust, and within the specified temperature range. For the IS215UCVEH2AB, verify the compatibility with the VME rack and other I/O boards it will be connected to. For the VMIVME – 7614 – 132, check the compatibility with the operating system it will run on and the expansion modules it may be connected to. Ensure that all the necessary tools for installation, such as screwdrivers and anti – static equipment, are available.

Maintenance recommendations: Regularly inspect the IS215UCVEH2AB and VMIVME – 7614 – 132 for any signs of physical damage, such as cracks on the circuit board or loose connections. Monitor their operating temperature and humidity levels to ensure they remain within the specified ranges. Clean the components periodically to remove dust that can accumulate over time and affect performance. Check the communication status of both components to ensure there are no data transfer issues. For the IS215UCVEH2AB, monitor the status LED indicators for any abnormal patterns. If any problems are detected, refer to the product manuals for troubleshooting steps or contact GE’s technical support team for assistance.

Product Guarantee

GE stands firmly behind the quality of the IS215UCVEH2AB and related components. The company ensures that these products are free from defects in materials and workmanship. In case of any quality – related issues during the warranty period, GE provides prompt repair or replacement services. Their team of experienced technicians is available to offer comprehensive technical support, helping customers with installation, configuration, and maintenance queries. GE’s long – standing reputation for reliability in the industrial automation field gives customers confidence in the performance of these components. The company’s commitment to customer satisfaction is evident in its after – sales service, making the IS215UCVEH2AB and related products reliable choices for industrial applications.