Description

Product Overview

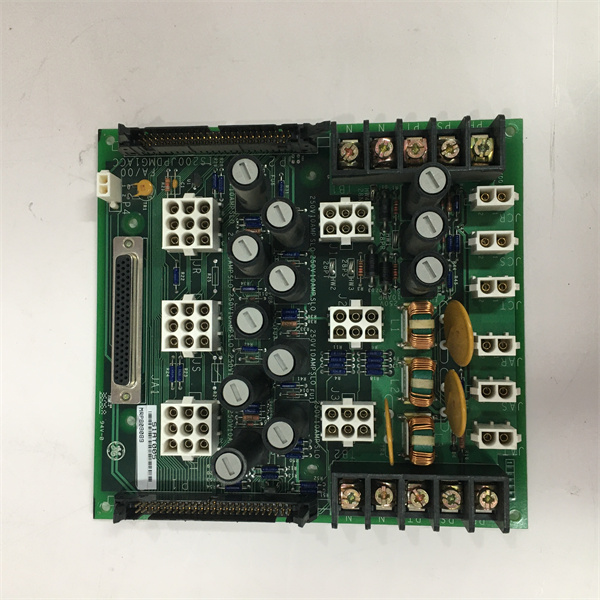

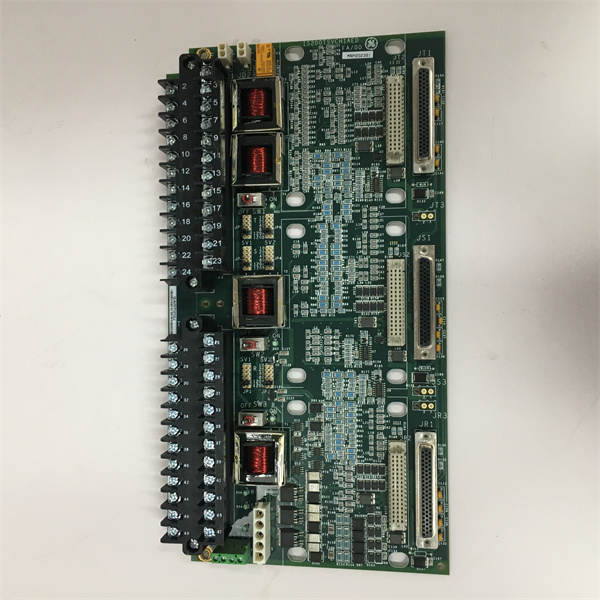

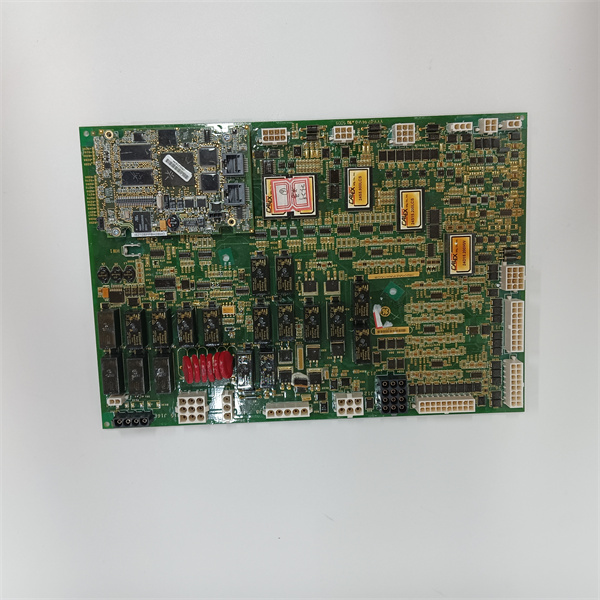

The GE IS210WSVOH1AE is a highly specialized and integral component within the GE industrial automation portfolio, particularly in the context of the Mark VI series used in the Speedtronic control systems. This board serves as a single – channel servo I/O terminal board, designed to perform critical functions in industrial control setups, especially those related to turbine control and monitoring.

It features two servo outputs, which are essential for precisely controlling the movement and operation of servo – based systems. These outputs can accurately regulate the speed, position, or torque of servo – driven devices, ensuring smooth and efficient operation in industrial processes. Additionally, it has I/O capabilities for six LVDT (Linear Variable Differential Transformer) position sensors. LVDT sensors are widely used in industrial applications to measure linear displacement accurately. By interfacing with these sensors, the IS210WSVOH1AE can monitor the position of various mechanical components in real – time, providing crucial feedback for control algorithms. The board also incorporates two active pulse – rate inputs for flow monitoring. This enables it to measure the flow rate of fluids or gases in industrial pipelines by counting the pulses from flow – measuring devices, contributing to better process control and optimization. Overall, the GE IS210WSVOH1AE plays a pivotal role in maintaining the reliability and performance of industrial control systems, enhancing the overall efficiency of industrial operations.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS210WSVOH1AE |

| Manufacturer | GE |

| Product Type | Single – channel servo I/O terminal board |

| Servo Outputs | 2 |

| LVDT Sensor I/O | 6 |

| Active Pulse – rate Inputs | 2 |

| Coil Current (example) | Jumper 120B provides ~120 mA |

| Operating Temperature | -20°C – 60°C |

| Relative Humidity | 5% – 95% non – condensing |

| Input Voltage | [Specify if available, not found in provided data] |

| Output Signal Types | [Details on types for servo outputs, etc., if available] |

| Dimensions (W x H x D) | [Specify if available, not found in provided data] |

| Weight | [Specify if available, not found in provided data] |

| Communication Interface | [Details on how it communicates with other components, if available] |

| Number of Terminals | [Details on the number of connection terminals, if available] |

IS200TSVCH1AED

Main Features and Advantages

Precise Servo Control: With two servo outputs, the GE IS210WSVOH1AE offers high – precision control over servo – based mechanisms. This is crucial in applications such as turbine control, where accurate regulation of speed and position is essential for optimal performance and safety. The board can drive servo motors with great accuracy, ensuring that industrial processes run smoothly and efficiently.

Comprehensive Sensor Integration: The ability to interface with six LVDT position sensors allows for comprehensive position monitoring. LVDT sensors are known for their high accuracy in measuring linear displacement. By integrating these sensors, the IS210WSVOH1AE can provide real – time, highly accurate position data. This is beneficial in applications like robotic arms in manufacturing plants or the control of valves in power generation facilities, where knowing the exact position of components is vital for proper operation.

Efficient Flow Monitoring: The two active pulse – rate inputs enable efficient flow monitoring. In industrial processes involving the transfer of fluids or gases, such as in chemical plants or oil refineries, accurately measuring the flow rate is crucial for process control and optimization. The board can quickly and accurately count the pulses from flow – measuring devices, providing reliable flow rate data that can be used to adjust process parameters and ensure the efficient use of resources.

Reliable Performance in Harsh Environments: Designed to operate within a temperature range of – 20°C to 60°C and a relative humidity of 5% – 95% non – condensing, the IS210WSVOH1AE is built to withstand harsh industrial environments. Whether it’s a hot and humid factory floor or a cold and dry industrial warehouse, the board can maintain its reliable performance, reducing the risk of system failures and downtime.

Comprehensive Sensor Integration: The ability to interface with six LVDT position sensors allows for comprehensive position monitoring. LVDT sensors are known for their high accuracy in measuring linear displacement. By integrating these sensors, the IS210WSVOH1AE can provide real – time, highly accurate position data. This is beneficial in applications like robotic arms in manufacturing plants or the control of valves in power generation facilities, where knowing the exact position of components is vital for proper operation.

Efficient Flow Monitoring: The two active pulse – rate inputs enable efficient flow monitoring. In industrial processes involving the transfer of fluids or gases, such as in chemical plants or oil refineries, accurately measuring the flow rate is crucial for process control and optimization. The board can quickly and accurately count the pulses from flow – measuring devices, providing reliable flow rate data that can be used to adjust process parameters and ensure the efficient use of resources.

Reliable Performance in Harsh Environments: Designed to operate within a temperature range of – 20°C to 60°C and a relative humidity of 5% – 95% non – condensing, the IS210WSVOH1AE is built to withstand harsh industrial environments. Whether it’s a hot and humid factory floor or a cold and dry industrial warehouse, the board can maintain its reliable performance, reducing the risk of system failures and downtime.

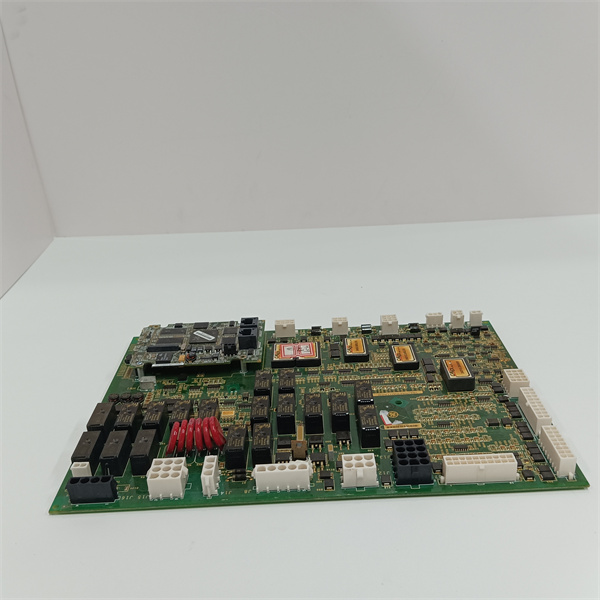

IS200AEPAH1ACB

Application Field

Power Generation: In power plants, especially those with gas turbines, the GE IS210WSVOH1AE is used for turbine control. It can control the servo – actuated components that regulate the fuel supply, air intake, and exhaust systems of the turbine. By monitoring the position of various mechanical parts using LVDT sensors and the flow rate of fuel and air, it ensures that the turbine operates at optimal efficiency, maximizing power output while minimizing fuel consumption.

Manufacturing Industry: In manufacturing plants, the board finds applications in robotic systems. The servo outputs can be used to control the movement of robotic arms, ensuring precise positioning for tasks such as pick – and – place operations, welding, and assembly. The LVDT sensor interfaces can monitor the position of the robotic joints, providing feedback to maintain accuracy. Additionally, in production lines where fluid or gas flow is involved, such as in the manufacturing of food and beverages or pharmaceuticals, the flow – monitoring capabilities of the IS210WSVOH1AE can be used to control the filling and dispensing processes.

Industrial Automation and Control Systems: In general industrial automation setups, this board can be integrated into control systems to manage a variety of processes. For example, in a water treatment plant, it can control the servo – driven valves that regulate the flow of water and chemicals, monitor the position of moving parts in pumps and filters using LVDT sensors, and measure the flow rate of treated water. This helps in ensuring the proper treatment of water and the efficient operation of the plant.

Manufacturing Industry: In manufacturing plants, the board finds applications in robotic systems. The servo outputs can be used to control the movement of robotic arms, ensuring precise positioning for tasks such as pick – and – place operations, welding, and assembly. The LVDT sensor interfaces can monitor the position of the robotic joints, providing feedback to maintain accuracy. Additionally, in production lines where fluid or gas flow is involved, such as in the manufacturing of food and beverages or pharmaceuticals, the flow – monitoring capabilities of the IS210WSVOH1AE can be used to control the filling and dispensing processes.

Industrial Automation and Control Systems: In general industrial automation setups, this board can be integrated into control systems to manage a variety of processes. For example, in a water treatment plant, it can control the servo – driven valves that regulate the flow of water and chemicals, monitor the position of moving parts in pumps and filters using LVDT sensors, and measure the flow rate of treated water. This helps in ensuring the proper treatment of water and the efficient operation of the plant.

Related Products

- GE IS200 series modules: These modules are part of the same Mark VI family. While the IS200 series may have different functions, such as digital signal processing (e.g., IS200DSPXH1D) or power supply management (e.g., IS200WNPSH1A), they can work in tandem with the IS210WSVOH1AE in a larger industrial control system. The IS200 series modules can handle specific control functions, and the IS210WSVOH1AE can provide the necessary I/O capabilities for sensor and actuator integration.

- GE Mark VIe DCS modules: The Mark VIe DCS (Distributed Control System) modules, like the IS210AEAAH1BKE, are designed for more comprehensive plant automation. They offer features such as enhanced communication capabilities, greater processing power, and more extensive I/O options. The IS210WSVOH1AE can be integrated with these modules to provide specific servo and sensor – related functions within the overall DCS framework, contributing to a more integrated and efficient control system.

- Sensor – specific modules: For example, modules that are specifically designed to interface with different types of sensors, such as thermocouple input modules (e.g., GE IS200VTCCH1C) or RTD (Resistance Temperature Detector) input modules (e.g., GE IS200VRTDH1D). These modules can work alongside the IS210WSVOH1AE when more complex sensor setups are required. The IS210WSVOH1AE focuses on LVDT sensors and servo control, while these sensor – specific modules handle other types of sensor inputs, together enabling a more diverse range of sensor – based control in industrial applications.

- Power supply modules: Products like the GE IC695PSA140 are power supply modules. A stable power supply is essential for the reliable operation of the IS210WSVOH1AE. The power supply module needs to provide the correct voltage and current to ensure the board functions properly, especially in industrial environments where power stability can be a challenge.

- Communication modules: Modules such as the GE IC695PBM300 (a Profibus master module) can be used in combination with the IS210WSVOH1AE. These communication modules expand the network connectivity options of the board, allowing it to communicate with other devices in the industrial network using different protocols, such as Profibus. This enables seamless data transfer and control in a multi – device industrial setup where the IS210WSVOH1AE can share its sensor data and receive control commands from other components in the network.

Installation and Maintenance

Pre – installation preparation: Before installing the GE IS210WSVOH1AE, ensure that the target system is powered off. Visually inspect the board for any signs of physical damage during transit. Since it is an electronic component, it is crucial to observe anti – static procedures. Wear an anti – static wrist strap and work on an anti – static mat. Familiarize yourself with the board layout, connectors, and terminals as described in the product manual. Check the compatibility of the IS210WSVOH1AE with the existing system components, including the power supply requirements, available slots in the chassis, and other connected devices. Make sure that the sensors (LVDT) and actuators (servo – related) that will be connected to the board are also in proper working condition and compatible with the board’s specifications.

Maintenance recommendations: Regularly monitor the IS210WSVOH1AE for any abnormal behavior, such as overheating, unusual noises, or incorrect outputs. Check the connections of all cables and wires to ensure they are secure. In case of any issues with the servo control, verify the calibration of the servo motors and the integrity of the servo output signals. If there are problems with the LVDT sensor readings, check the sensor alignment and calibration. Since the board is designed to operate in harsh environments, periodically clean it to remove dust and debris, as these can affect its performance over time. Keep an eye on software – related issues, such as firmware updates, and apply them as recommended by GE to ensure optimal performance and compatibility with other system components.

Maintenance recommendations: Regularly monitor the IS210WSVOH1AE for any abnormal behavior, such as overheating, unusual noises, or incorrect outputs. Check the connections of all cables and wires to ensure they are secure. In case of any issues with the servo control, verify the calibration of the servo motors and the integrity of the servo output signals. If there are problems with the LVDT sensor readings, check the sensor alignment and calibration. Since the board is designed to operate in harsh environments, periodically clean it to remove dust and debris, as these can affect its performance over time. Keep an eye on software – related issues, such as firmware updates, and apply them as recommended by GE to ensure optimal performance and compatibility with other system components.

Product Guarantee

GE provides a comprehensive product guarantee for the GE IS210WSVOH1AE. The company stands firmly behind the quality of the product, ensuring that it is free from defects in materials and workmanship. In case of any quality – related issues during the warranty period, GE offers reliable after – sales service. Their technical support team is readily available to assist customers with installation guidance, troubleshooting technical problems, and providing advice on optimizing the performance of the IS210WSVOH1AE. If a defect is identified, GE will either repair or replace the product promptly, demonstrating their commitment to customer satisfaction and the long – term, trouble – free operation of industrial control systems that rely on this critical I/O terminal board.