Description

Product Overview

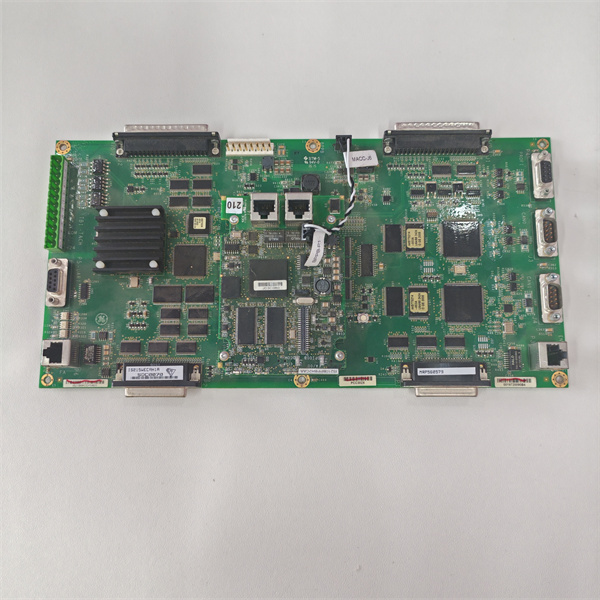

The GE IS210MACCH1AKH is a crucial controller module within the GE Mark VIe control system. General Electric, a globally recognized leader in industrial technology, designed this module to meet the stringent demands of modern industrial automation and control applications.

This module serves as a central processing and control unit, offering high – performance capabilities for real – time data handling and control command execution. It is engineered to manage complex operations, making it suitable for a wide range of industries. For instance, in power generation plants, the IS210MACCH1AKH can precisely control the operation of turbines by processing data from various sensors such as temperature, pressure, and speed sensors. It then adjusts the control parameters to ensure optimal power generation efficiency. In industrial automation settings, it can coordinate the movement of conveyor belts, robotic arms, and other machinery in a manufacturing line, ensuring seamless production flow. Its role in these applications is fundamental to maintaining system stability and maximizing productivity.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS210MACCH1AKH |

| Manufacturer | General Electric |

| Product Type | Controller Module |

| Compatible System | GE Mark VIe |

| Communication Protocols | Ethernet, RS – 232, RS – 485, Modbus (and potentially others for industrial connectivity) |

| Power Input | Industrial standard input voltage range |

| Operating Temperature Range | – 30 °C to 70 °C |

| Dimensions | 3.5 cm x 13 cm x 13.5 cm (approximate, based on related model) |

| Weight | 0.3 kg (approximate, based on related model) |

| Connector Type | 37 – pin connector (approximate, based on related model) |

IS210MACCH1AKH

Main Features and Advantages

High – Performance Processing

The IS210MACCH1AKH is equipped with a powerful processor. This enables it to handle real – time data at high speeds, allowing for quick decision – making and control actions. In a power generation scenario, it can rapidly analyze changes in turbine conditions and adjust the fuel supply or blade angles within milliseconds, ensuring stable power output.

Multitasking Capability

Capable of managing multiple tasks simultaneously, the module is well – suited for complex control scenarios. In an industrial automation plant, it can control the speed of conveyor belts, monitor the operation of robotic arms, and manage the quality control sensors all at the same time, optimizing the overall production process.

Robust Design for Harsh Environments

Designed with industrial durability in mind, the IS210MACCH1AKH can withstand harsh conditions. It is resistant to high temperatures, vibrations, and electromagnetic interference, which are common in industrial settings. This ensures reliable operation even in the most challenging environments, such as inside a power plant with high – temperature turbines or a manufacturing facility with large – scale machinery generating vibrations.

Versatile Communication

Supporting a wide range of industrial – standard communication protocols like Ethernet, RS – 232, RS – 485, and Modbus, the module can easily integrate with other devices and systems. This allows for seamless data exchange between different components of an industrial control network, whether it’s connecting to sensors, actuators, or other control modules.

Application Field

The GE IS210MACCH1AKH has diverse applications across multiple industries.

In the energy production sector, particularly in gas and steam turbine power plants, it plays a critical role. It controls the operation of turbines, monitors their performance, and adjusts parameters to ensure efficient power generation. By precisely controlling the fuel – air mixture and turbine speed, it helps to maximize energy output while minimizing fuel consumption and emissions.

In industrial automation, it is used in manufacturing plants. For example, in an automotive assembly line, the IS210MACCH1AKH can manage the movement of parts on conveyor belts, control the actions of robotic arms during welding and assembly processes, and ensure the proper functioning of quality control sensors. This results in improved production efficiency and product quality.

It also finds applications in the oil and gas industry. Here, it can be used to control the operation of pumps, compressors, and other equipment in oil refineries and gas processing plants. By monitoring and controlling variables such as pressure, flow rate, and temperature, it helps to maintain the safe and efficient operation of these facilities.

IS210MACCH1AKH

Related Products

- IS210MACCH2AKH: Another multi – function I/O controller in the same series. It may have additional I/O capabilities or different communication interface configurations compared to IS210MACCH1AKH, making it suitable for applications with more complex I/O requirements.

- IS210BPPBH2CAA: A process control module from GE. While the IS210MACCH1AKH focuses on overall control and processing, the IS210BPPBH2CAA is more specialized in industrial process management, such as in power generation and oil – gas operations, and may work in tandem with IS210MACCH1AKH in some systems.

- IS210MACCH2AFG: A programmable logic controller within the GE product range. It likely has its own set of features, such as specific programming capabilities or different input – voltage requirements, which can be chosen based on the unique needs of an industrial control application instead of or along with IS210MACCH1AKH.

- IS210MACCH2AEG: Part of GE’s IS200 series, designed for high – reliability in industrial automation. It may offer different levels of performance, memory capacity, or scalability compared to IS210MACCH1AKH, providing options for users with varying system requirements.

- DS200TCEAG1BTF: An emergency – overspeed board in GE’s Speedtronic MKV gas – turbine control system. It has a specialized function of handling turbine overspeed situations, which is different from the general – purpose control functions of IS210MACCH1AKH, but they can both be part of a comprehensive gas – turbine control setup.

Installation and Maintenance

Pre – installation preparation: Before installing the GE IS210MACCH1AKH, ensure that the power to the relevant system is switched off. Check the compatibility of the module with the existing GE Mark VIe system components, including ensuring proper voltage levels and communication interface compatibility. Clean the installation area to prevent dust and debris from interfering with the module’s operation. Inspect the module for any visible signs of damage during transportation.

Maintenance recommendations: Regularly monitor the IS210MACCH1AKH for any abnormal behavior, such as overheating, unusual noises, or communication errors. Periodically clean the module to remove any accumulated dust, as this can affect its performance over time. Check the connection points to ensure they are secure. If any issues are detected, refer to the detailed product manual provided by GE for troubleshooting steps. GE also offers software updates from time to time, so it’s important to keep the module’s software up – to – date to benefit from performance improvements and bug fixes.

Product Guarantee

GE offers a comprehensive product guarantee for the IS210MACCH1AKH. The company is committed to the quality of this controller module, having implemented strict quality – control measures during the manufacturing process. In case of any manufacturing defects within the warranty period, GE provides free repair or replacement services. Their global network of technical support teams is available to offer assistance, whether it’s for installation guidance, troubleshooting technical issues, or providing advice on system optimization. This demonstrates GE’s confidence in the reliability and performance of the IS210MACCH1AKH, giving customers peace of mind when using this module in their industrial applications.